Cutting method for wafer with irregularly-distributed chips

A cutting method and irregular technology, which is applied in the field of wafer cutting with irregular distribution of chips, can solve the problems of not being applicable to chip irregular wafer cutting, etc., to improve cutting efficiency, eliminate the influence of rotation angle, and have a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

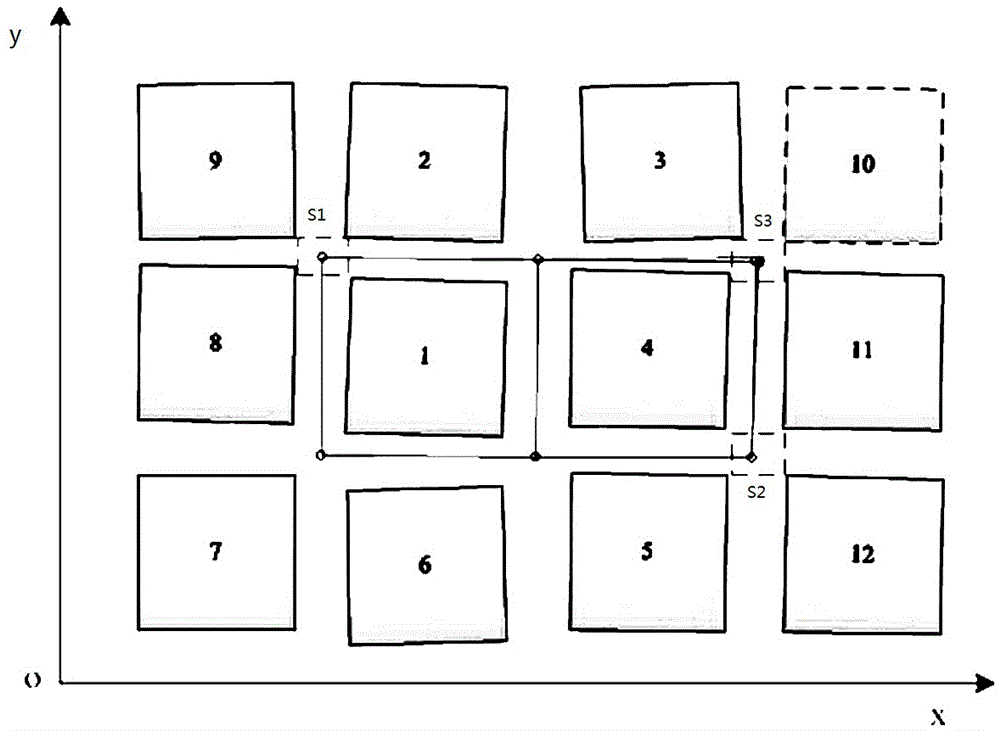

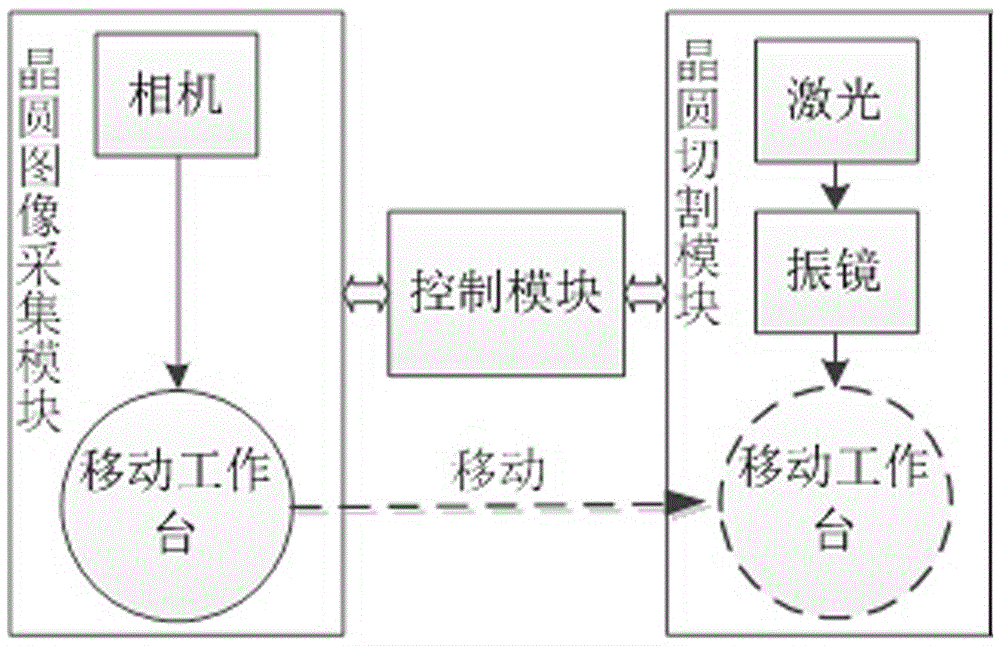

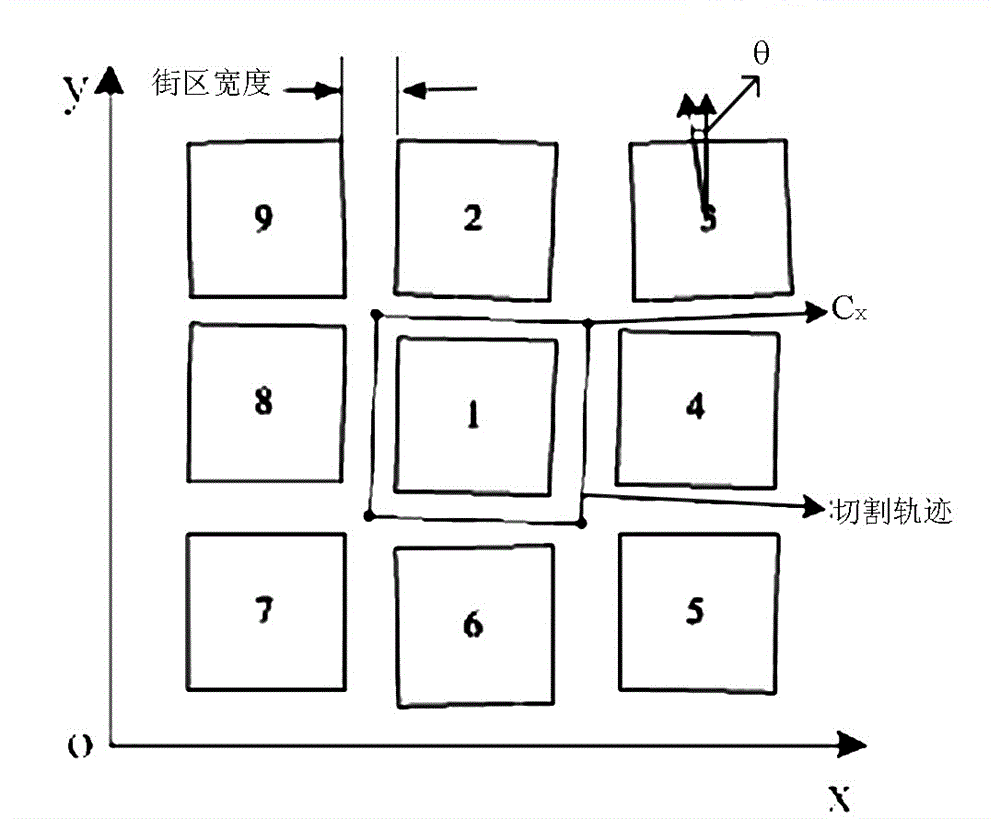

[0053] The present invention proposes a laser cutting method for wafers with irregularly distributed chips. It mainly obtains the center position and rotation angle of the chip through image recognition, calculates each cutting corner of the chip based on this, and cuts each of the intersections of the blocks. The corner points are equalized and corrected, and the position information of the entire wafer is finally obtained, and laser cutting is performed along the cutting track of the chip through a galvanometer. The chip shape in this method can be a polygon such as a quadrilateral, a pentagon, and a hexagon.

[0054] Such as Figure 1-7 As shown, this wafer cutting method with irregular chip distribution uses a mobile worktable and a camera to achieve a full scan of the entire wafer. For each frame of image in the scanning process, a template matching method is used to identify each to-be-processed The center position and rotation angle of the chip, and calculate the center po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com