Two-sided printer adopting vertical printing manner

A technology for printers and printing mechanisms, applied in typewriters, printing, etc., can solve the problems of easy jamming of paper or fabrics, easy dislocation of images, etc., to achieve the effect of overlapping and meeting printing needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

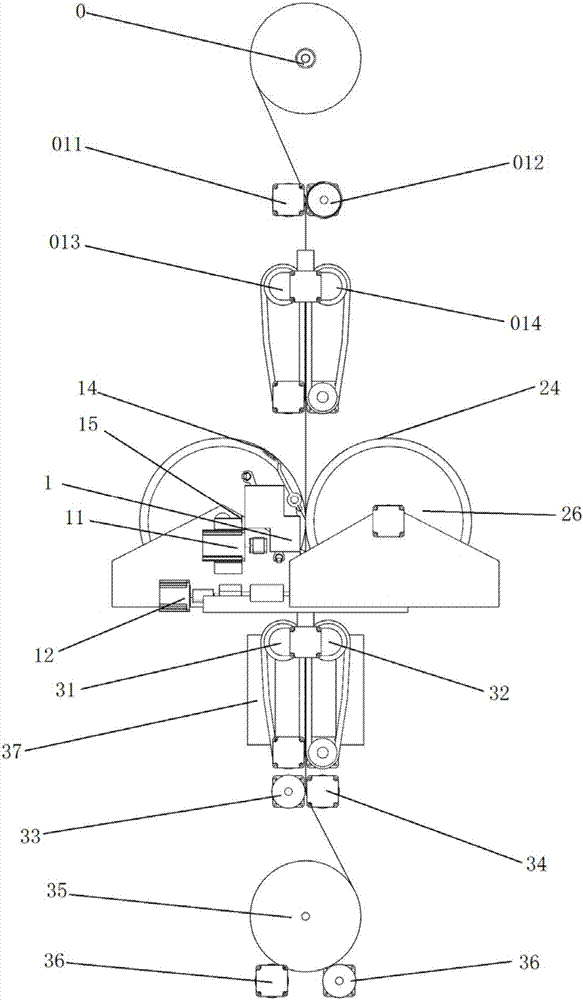

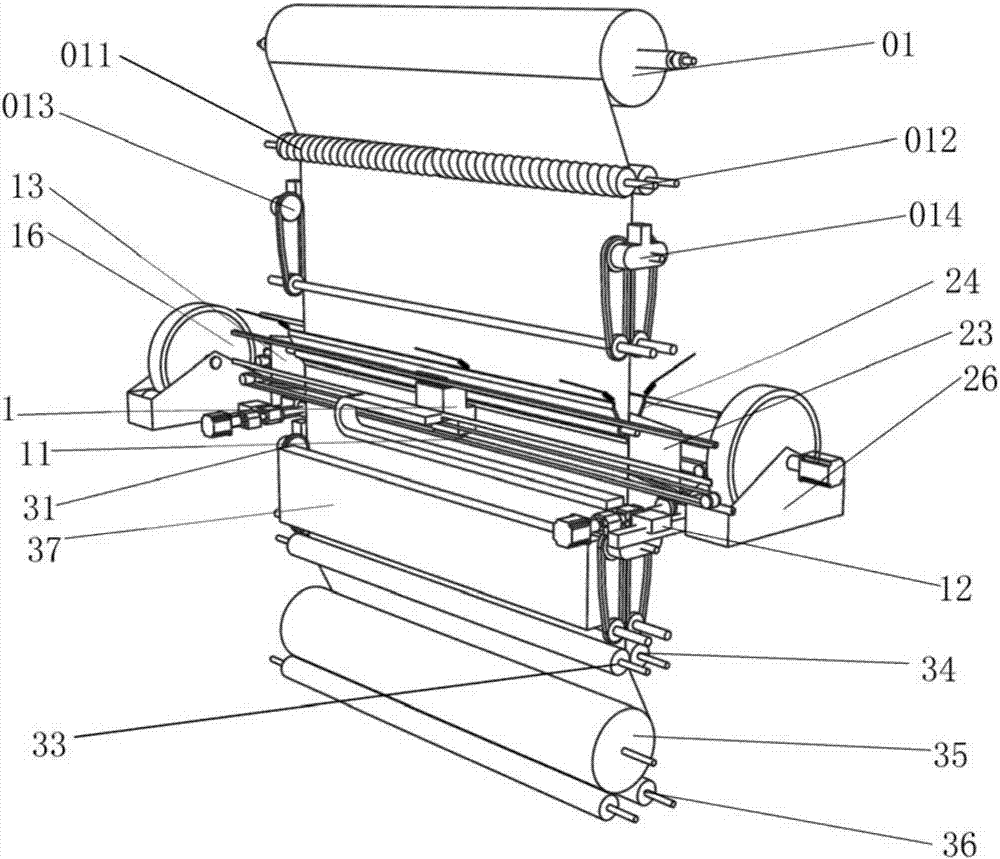

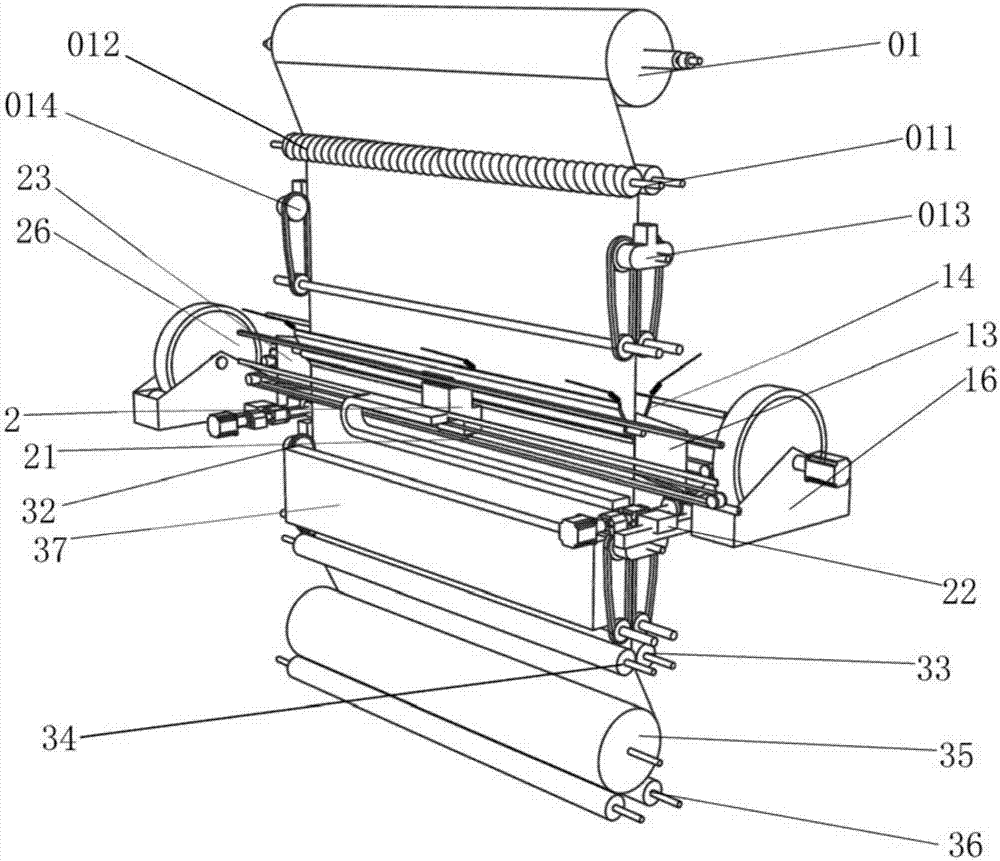

[0042] A double-sided printer that prints vertically, such as figure 1 As shown, including the bracket, the bracket is provided with a cloth feeding mechanism, a printing mechanism and a cloth receiving mechanism. It is arranged on another branch bracket in the bracket. In this embodiment, the cloth feeding mechanism, the printing mechanism and the cloth receiving mechanism are arranged sequentially from top to bottom, and the optimal arrangement is the cloth feeding mechanism, the printing mechanism and the receiving mechanism. The cloth mechanisms are arranged vertically, so that the conveying of the fabric process can be guaranteed. In order to carry out double-sided printing more conveniently, the printing mechanism includes a first printing assembly and a second printing assembly; the first printing assembly is used to print on the first side of the fabric, including the first nozzle 1 for ink output and The first nozzle movement servo system 11 that controls the movemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com