Control method and control system for width centering of steel coil carried by steel coil car

A technology of steel coil car and steel coil, which is applied in the field of continuous processing of metallurgical cold rolling, can solve the problems of strip edge quality, influence, damage to equipment, etc., and achieve the effects of simple implementation, improved automatic production capacity, and easy programming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment, the present invention is further described:

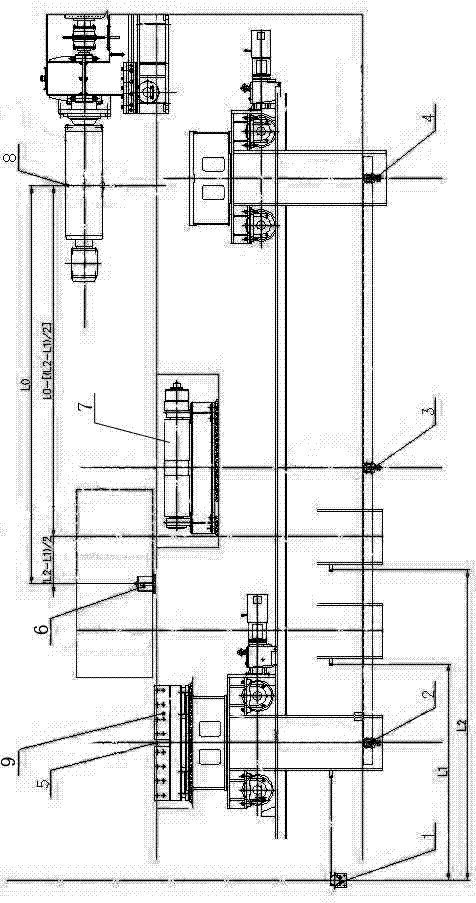

[0020] Such as figure 1 The control system for centering the width of the steel coil carried by the steel coil car includes a saddle seat 9, a ground roller position 7, a reel 8, a steel coil car and a track for the steel coil car, wherein the steel coil car is provided with The V-shaped saddle can be lifted and lowered, and an absolute value rope encoder 1 is installed under the track. The rope of the encoder is connected horizontally with the frame of the steel coil trolley, and the steel coil trolley retreat limit position is respectively installed under the track. Stroke switch 2, coil car advance limit position travel switch 4, steel coil car deceleration position travel switch 3, respectively corresponding to the front and rear limit positions and deceleration positions of the steel coil car, and a coil proximity switch 5, a coil proximity switch 5, and a coil The width d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com