System capable of realizing optical lens and focal plane assembly high-precision centering, and method capable of realizing optical lens and focal plane assembly high-precision centering

An optical lens, high-precision technology, used in optical components, optics, instruments, etc., can solve problems such as inability to meet requirements, and achieve the effect of simple structure, easy operation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

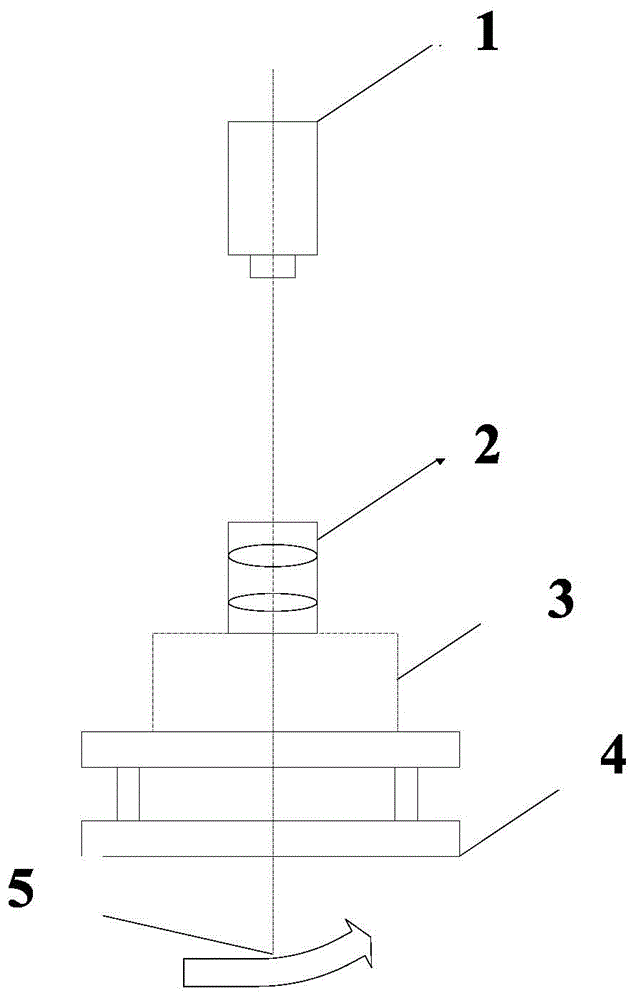

[0015] Such as figure 1 As shown, the present invention provides a system capable of realizing high-precision centering of optical lenses and focal plane components, including an autocollimation centering device 1 , an optical lens 2 , a focal plane component 3 , a two-dimensional adjustment table 4 , and a rotating shaft 5 . The focal plane assembly is set on the two-dimensional adjustment table; the optical lens is set on the focal plane assembly; the rotation shaft is connected to the two-dimensional adjustment table and drives the optical lens and the focal plane assembly to rotate axially around the rotation axis through the two-dimensional adjustment table; The lens and the focal plane assembly are sequentially arranged on the outgoing light path of the autocollimation and centering instrument. The two-dimensional adjustment table can realize translation and pitch adjustment, the translation accuracy is 0.01mm, and the pitch adjustment accuracy is 5".

[0016] Concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com