Manufacturing method of multilayer flexible circuit board and manufactured product

A technology for flexible circuit boards and manufacturing methods, applied in multilayer circuit manufacturing, printed circuit manufacturing, circuit substrate materials, etc., can solve the problem of increased power consumption and signal transmission loss, large dielectric constant and loss factor, and poor structural characteristics etc. to achieve low power consumption and high-frequency signal transmission loss, improve production and processing efficiency, and improve signal transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further illustrate the technical means and functions adopted by the present invention to achieve the intended purpose, the specific implementation modes of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0042] An embodiment of the present invention provides a method for manufacturing a multilayer flexible circuit board, including the following steps:

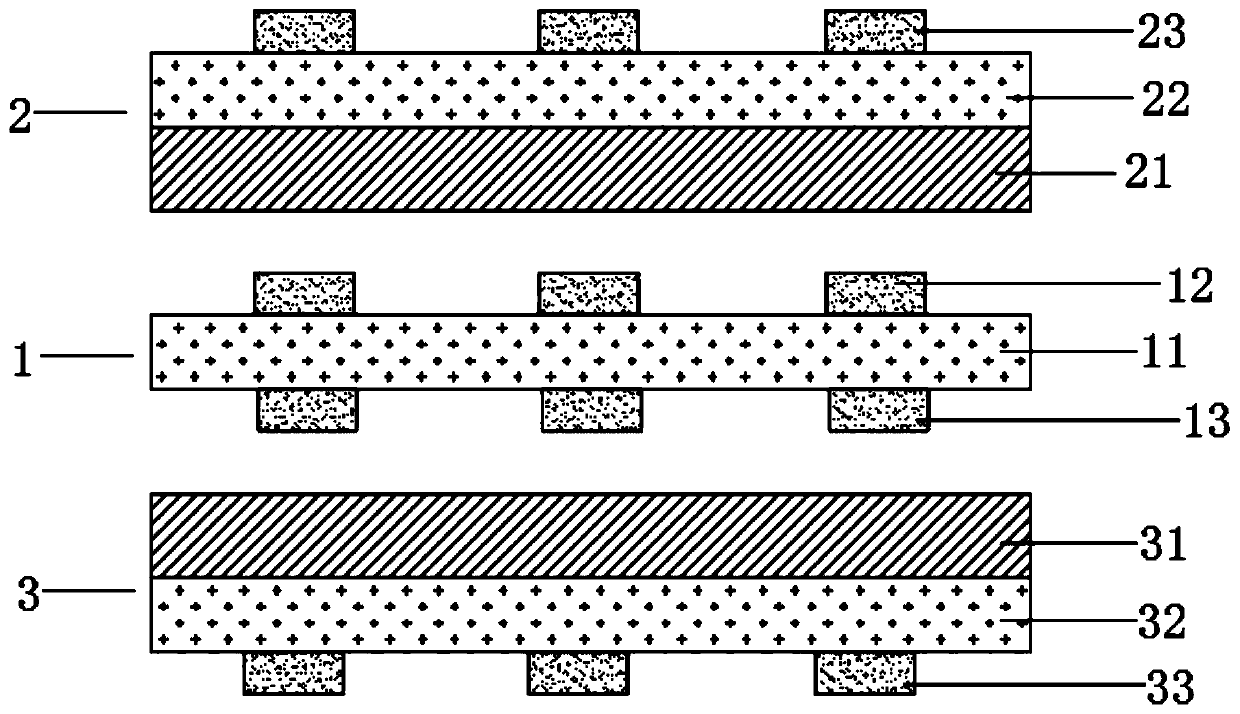

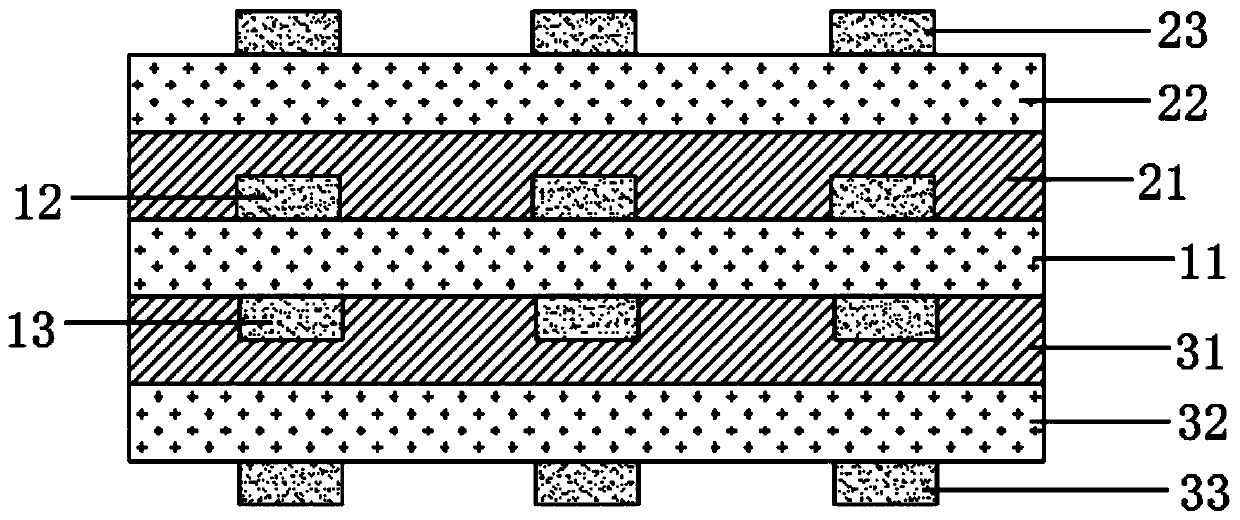

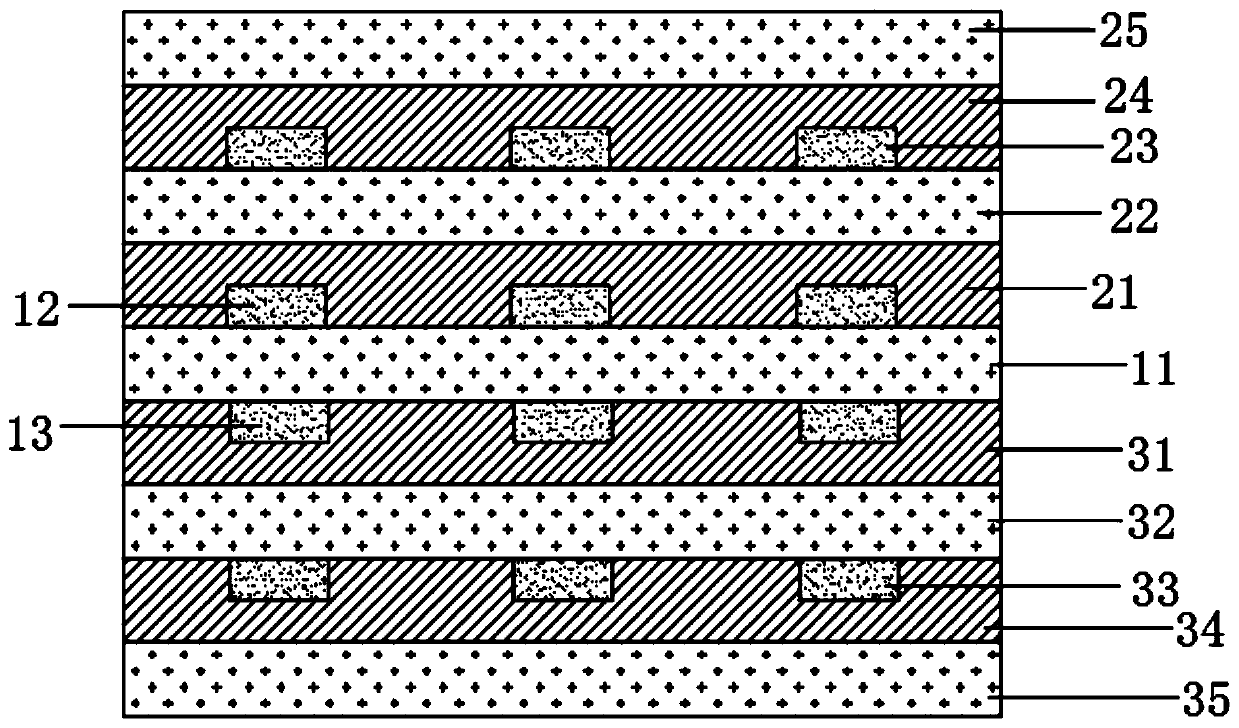

[0043] (1) Making a double-sided FPC flexible board: apply a copper layer on the upper and lower surfaces of the base film, and form a circuit on the copper layer to obtain a double-sided FPC flexible board;

[0044] (2) Make at least one set of new material layer structures

[0045] (2.1) Apply a copper layer on the first surface of the film to form a single panel;

[0046] (2.2) Apply a semi-cured high-frequency material layer on the other surface of the single-sided film to obtain at least one set of new material layer stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com