Demand-oriented geometric feature-driving turbine disc structure interactive design method

A design method and geometric feature technology, applied in geometric CAD, computer-aided design, design optimization/simulation, etc., can solve problems such as wasting time, wasting manpower, time-consuming and laborious, and achieve the effect of reducing human resources and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

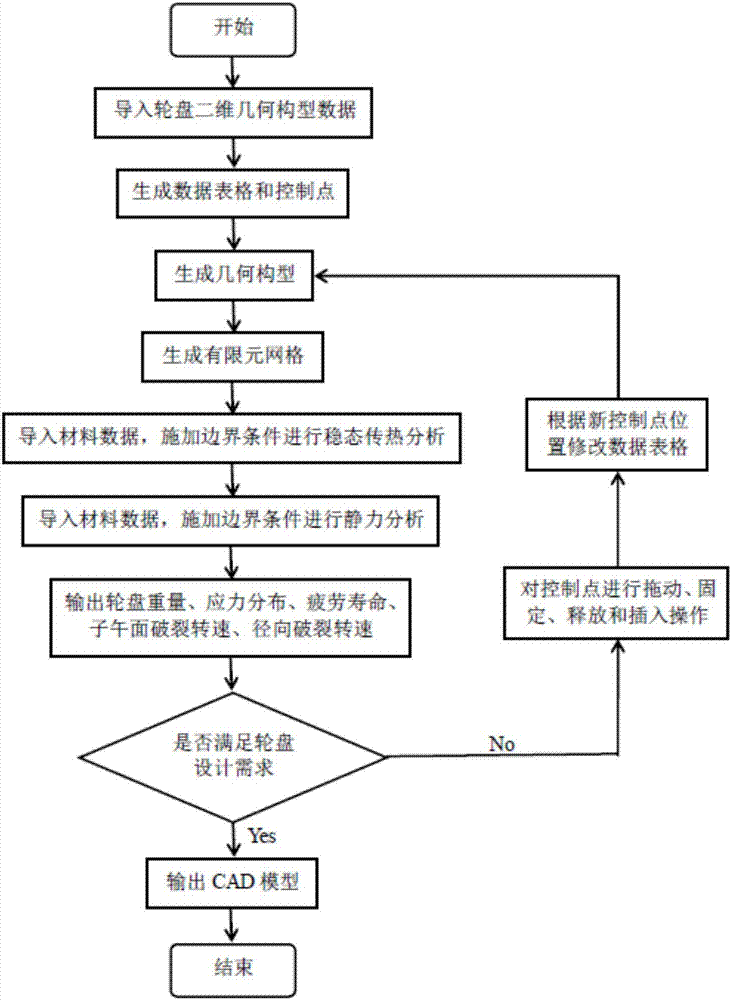

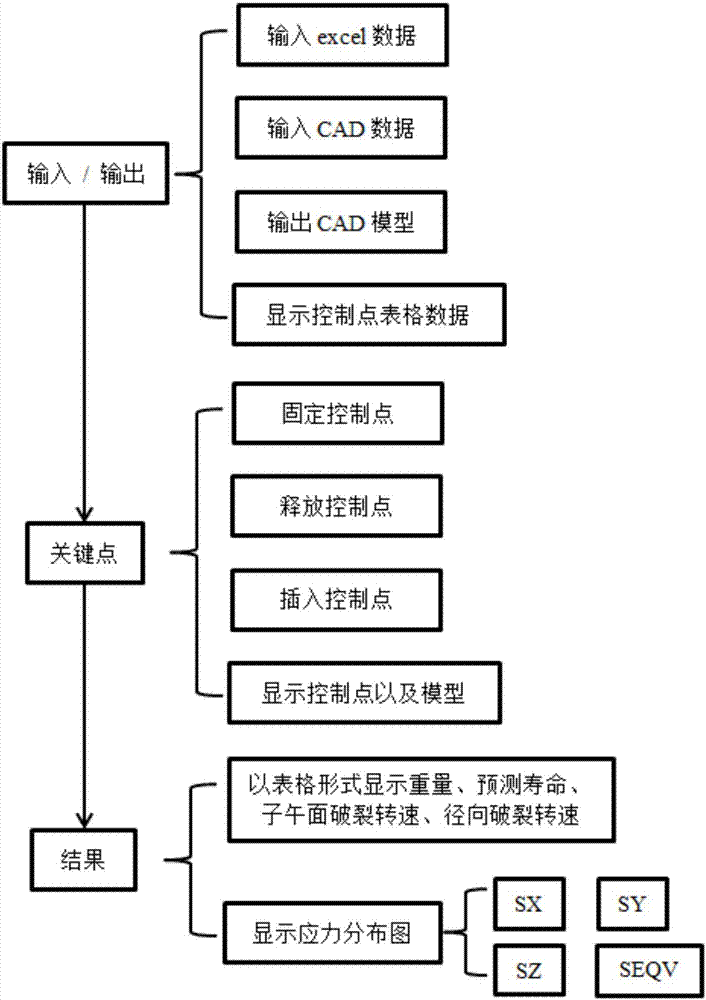

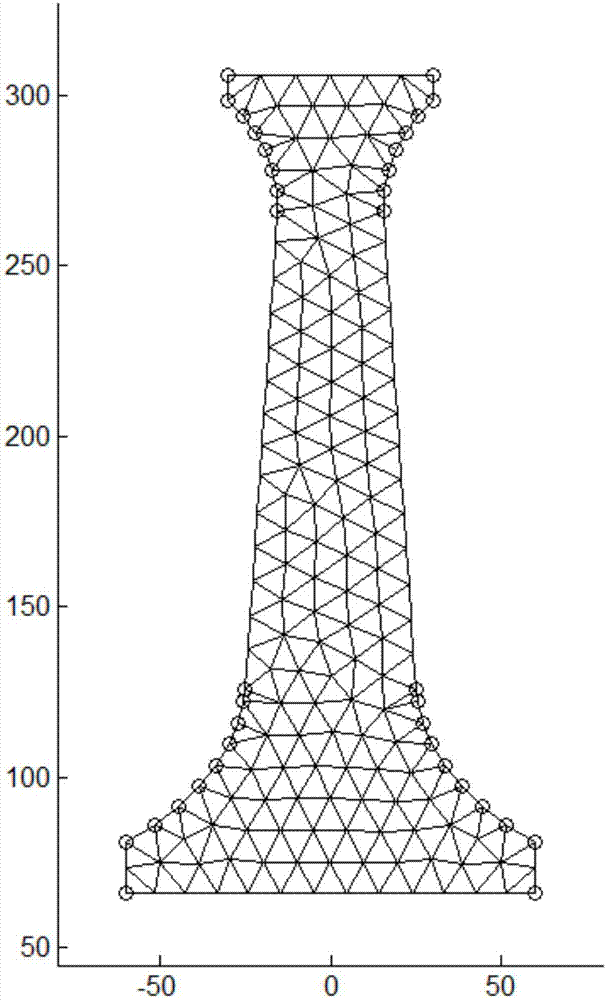

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples; the present invention is a demand-oriented and geometric feature-based driving wheel structure interactive design method, which is to drag and fix the two-dimensional geometric configuration control points of the wheel , release and insert to change the 2D geometric configuration of the roulette, and automatically display the control points of the 2D geometric configuration of the roulette, the coordinate values of the control points of the 2D geometric configuration of the roulette, the weight of the roulette, the results of finite element analysis, and the fatigue life Prediction results, meridian rupture speed and radial rupture speed.

[0039] The flow chart of a demand-oriented interactive design method for driving a wheel structure based on geometric features in the present invention is as follows: figure 1 As shown, the specific steps are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com