Method for preparing sand-shaped aluminum oxide

A technology of alumina and aluminum hydroxide, applied in the field of aluminum metallurgy, can solve the problems that boehmite technology cannot be industrialized, it is difficult to meet the problems of sandy alumina, and the decomposition rate of boehmite is low, and it is beneficial to aluminum Electrolysis, easy industrial implementation, saving effect of roasting energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

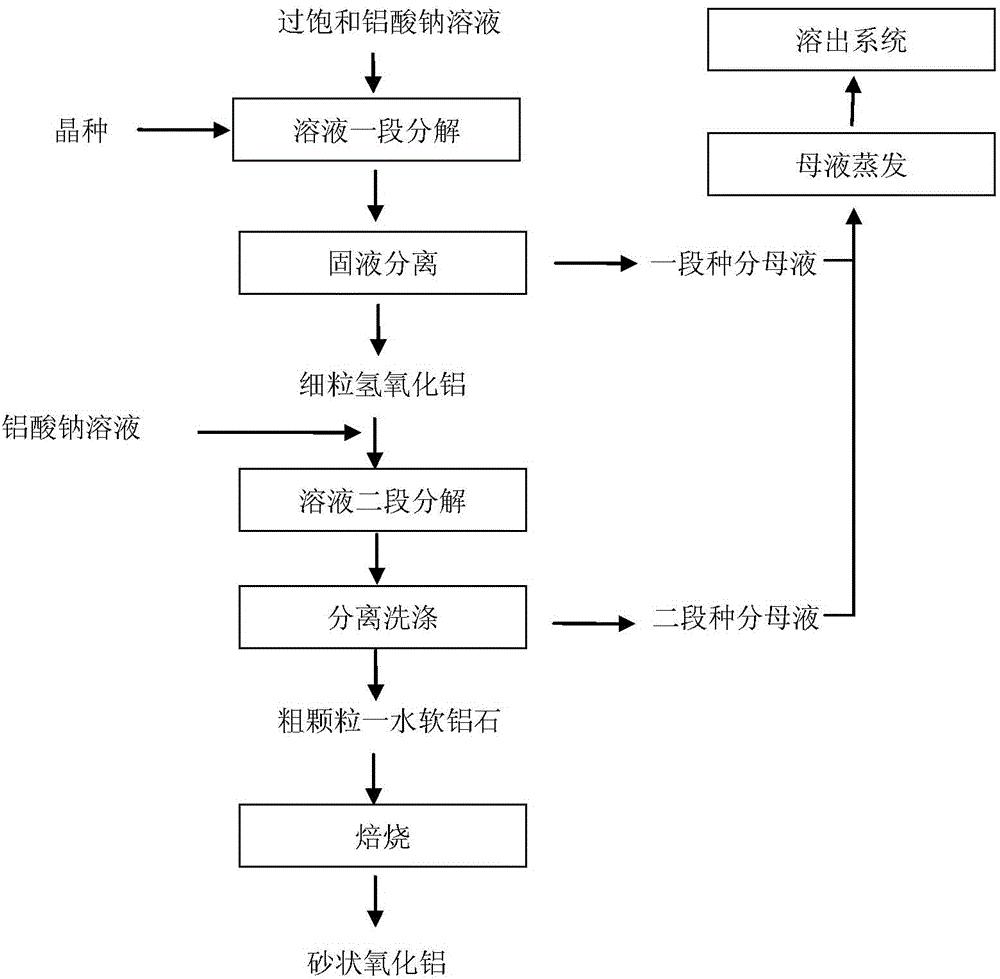

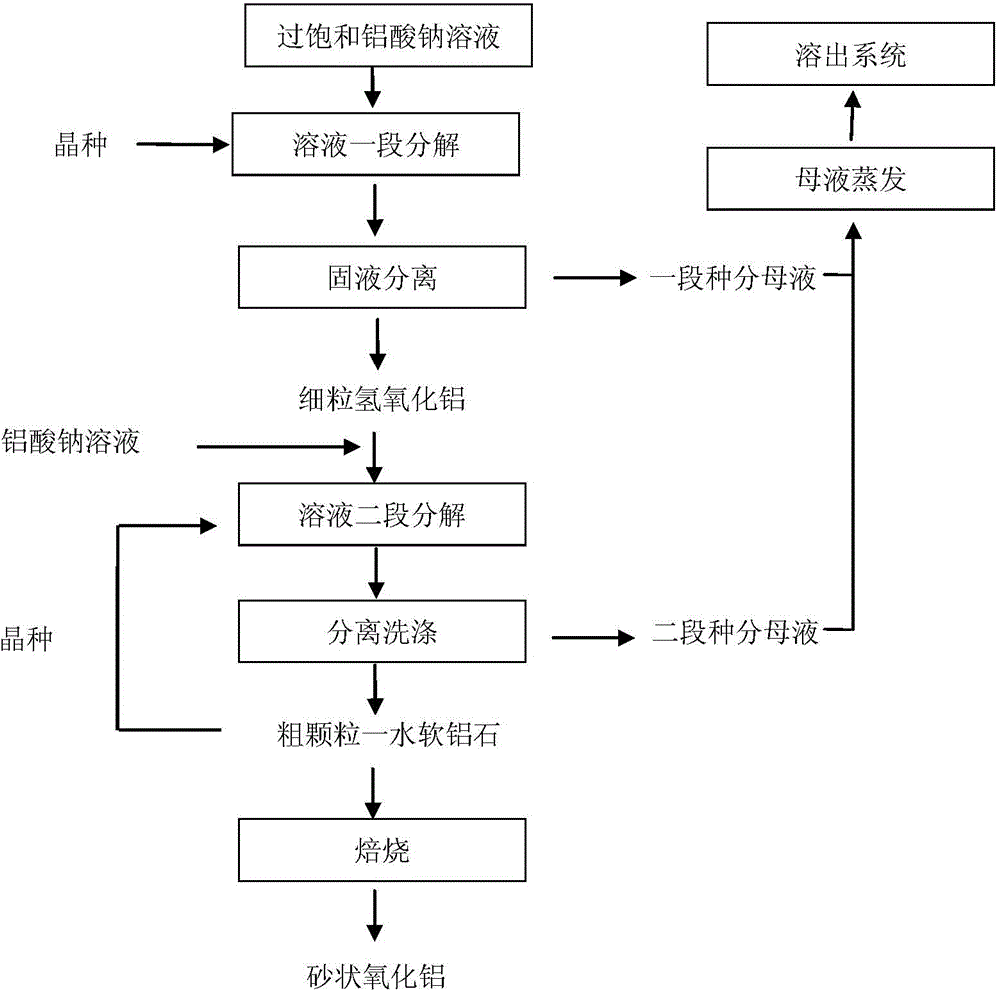

[0035] The preparation method of sandy alumina of the present invention, technological process such as figure 1 As shown, take 40ml supersaturated sodium aluminate solution (Na 2 O=162g / L, Al 2 o 3 =187.2g / L, α k =1.42), add 50ml sodium bicarbonate suspension (NaHCO 3 =45g / L), stirred at 30°C for 60min to obtain activated aluminum hydroxide seeds.

[0036] 900ml supersaturated sodium aluminate solution (Na 2 O=162g / L, Al 2 o 3 =187.2g / L, α k=1.42) into the seeding tank, add the active aluminum hydroxide crystal seed prepared above while stirring, start a section of seeding, a section of seeding adopts constant temperature decomposition, the decomposition temperature is 45 ° C, and end a section of seeding after 40 hours of decomposition , filter the slurry after seed separation to obtain a section of seed separation mother liquor and aluminum hydroxide. Aluminum hydroxide is washed to obtain a decomposed aluminum hydroxide. The average particle size d of the aluminum...

Embodiment 2

[0040] The preparation method of sandy alumina of the present invention, technological process such as figure 1 As shown, take 50ml supersaturated sodium aluminate solution (Na 2 O=151g / L, Al 2 o 3 =188.9g / L, α k =1.31), add 50ml sodium bicarbonate suspension (NaHCO 3 =35g / L), stirred at 25°C for 30min to obtain activated aluminum hydroxide seeds.

[0041] Add 900ml of supersaturated sodium aluminate solution into the seeding tank, add the above-prepared activated aluminum hydroxide seed crystals while stirring, start a section of seeding, and use cooling to decompose for a section of seeding, decompose at 50°C for 10 hours and then drop to 45°C, decompose for another 30 hours, filter the slurry after the seed separation, and obtain a section of seed separation mother liquor and aluminum hydroxide. Aluminum hydroxide is washed to obtain a decomposed aluminum hydroxide. The average particle size d of the decomposed aluminum hydroxide 50 =12.1μm, Na in the product 2 The ...

Embodiment 3

[0045] The preparation method of sandy alumina of the present invention, technological process such as figure 1 As shown, take 30ml supersaturated sodium aluminate solution (Na 2 O=165g / L, Al 2 o 3 =180.6g / L, α k =1.50), adding 50ml concentration of 10% hydrogen peroxide, stirred at 30°C for 60min to obtain active aluminum hydroxide seed crystals.

[0046] Add 900ml of supersaturated sodium aluminate solution into the seeding tank, add the above-prepared activated aluminum hydroxide seed crystals while stirring, start a section of seeding, and decompose at a constant temperature for a section of seeding at 55°C for 40 hours Finally, a section of seed separation is completed, and the slurry after seed separation is filtered to obtain a section of seed separation mother liquor and aluminum hydroxide. Aluminum hydroxide is washed to obtain a decomposed aluminum hydroxide. The average particle size d of the decomposed aluminum hydroxide 50 =25.6 μm; the decomposition rate of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com