Phase-change thermoregulation microcapsule and preparing method thereof

A microcapsule and phase change technology, applied in the field of materials, can solve the problems of poor phase controllability in the phase change interval, high monomer toxicity, and small proportion of effective energy storage molecules, and achieve excellent performance, no volatile toxicity, and phase change Interval stable and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation of embodiment 1 phase-change thermoregulation microcapsules (butyl stearate 80%)

[0040] 80-mesh expandable graphite was treated with 150W microwave for 5-10s to form worm-like porous graphite, and 80% of the total mass fraction of graphite and phase change material (butyl stearate) was added with butyl stearate, treated at 80°C for 30 minutes, Stir well, and then process at 80°C for 30 minutes to complete the adsorption, and cool naturally to obtain phase-change temperature-regulated microcapsules.

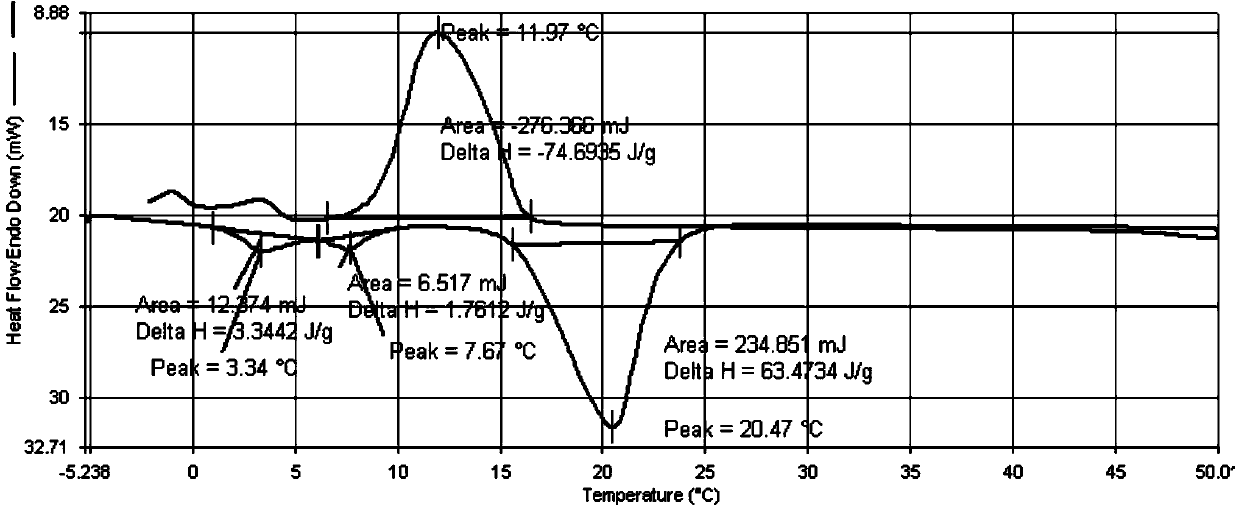

[0041] The DSC phase change curve figure of gained phase change thermoregulation microcapsule is as follows image 3 As shown, Tm=20°C; Tc=12°C; ΔHm=63J / g; ΔHc=75J / g.

Embodiment 2

[0042] The preparation of embodiment 2 phase-change thermoregulation microcapsules (butyl stearate 85%)

[0043] 80-mesh expandable graphite was treated with 150W microwave for 5-10s to form worm-like porous graphite, and 85% of the total mass fraction of graphite and phase change material (butyl stearate) was added with butyl stearate, and treated at 80°C for 30 minutes. Stir well, and then process at 80°C for 30 minutes to complete the adsorption, and cool naturally to obtain phase-change temperature-regulated microcapsules.

[0044] The DSC phase change curve figure of gained phase change thermoregulation microcapsule is as follows Figure 4 As shown, Tm=19°C; Tc=13°C; ΔHm=65J / g; ΔHc=69J / g.

Embodiment 3

[0045] The preparation of embodiment 3 phase-change thermoregulation microcapsules (n-octadecane 80%)

[0046]Use 80-mesh expandable graphite, treat it with 150W microwave for 5-10s to form worm-like porous graphite, add n-octadecane with a total mass fraction of graphite and phase change material (n-octadecane) of 80%, treat at 80°C for 30 minutes, and stir well , treated at 80°C for 30 minutes to complete the adsorption, and cooled naturally to obtain phase-change temperature-regulated microcapsules.

[0047] The DSC phase change curve figure of gained phase change thermoregulation microcapsule is as follows Figure 5 As shown, Tm=33°C; Tc=17°C; ΔHm=127J / g; ΔHc≈130J / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com