Ni2P/reduced graphene oxide catalyst for hydrodeoxygenation reaction of bio-oils and preparation method thereof

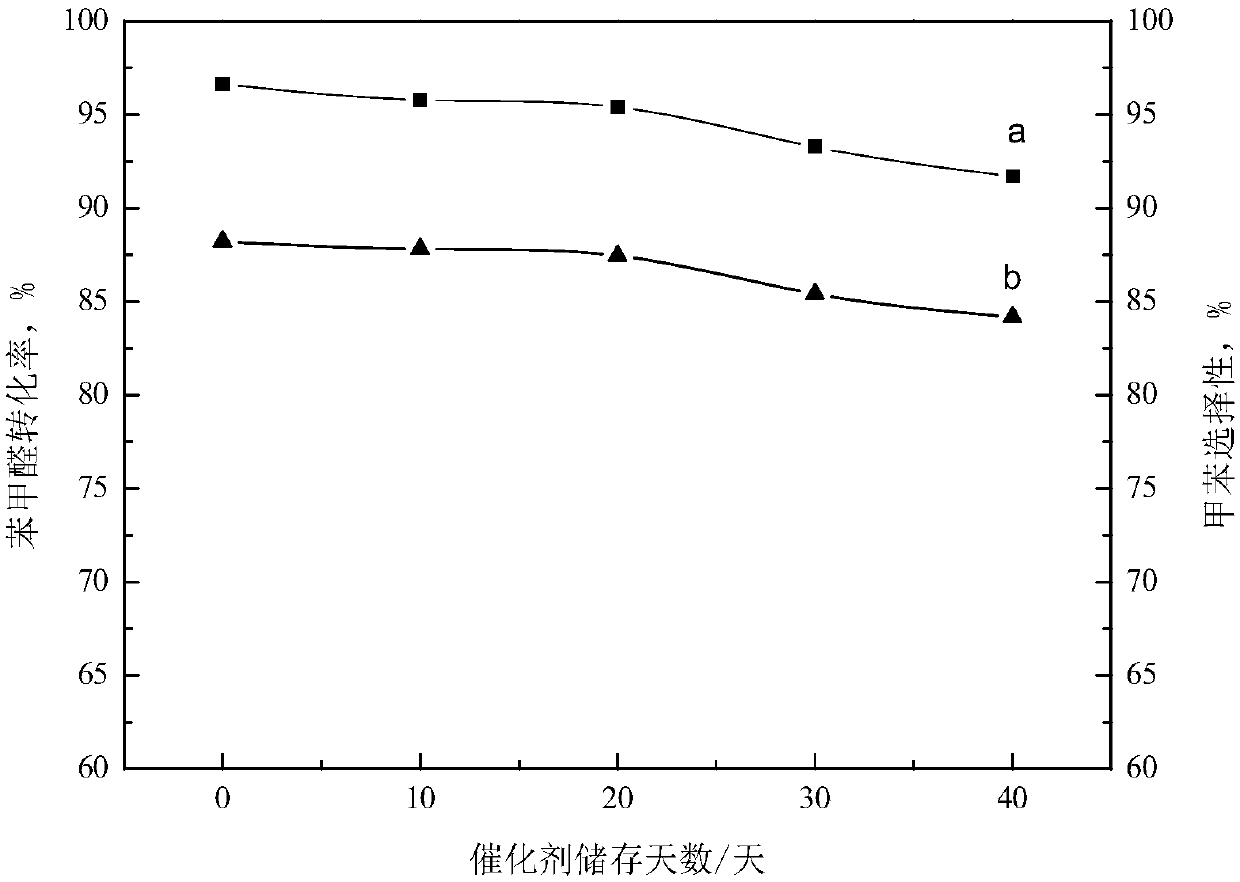

A hydrodeoxygenation and catalyst technology, which is used in physical/chemical process catalysts, preparation of liquid hydrocarbon mixtures, biological raw materials, etc., can solve problems such as adverse effects of catalyst storage, easy deactivation during storage time, and inability of phosphate to be reduced. Achieve significant application value, good stability and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

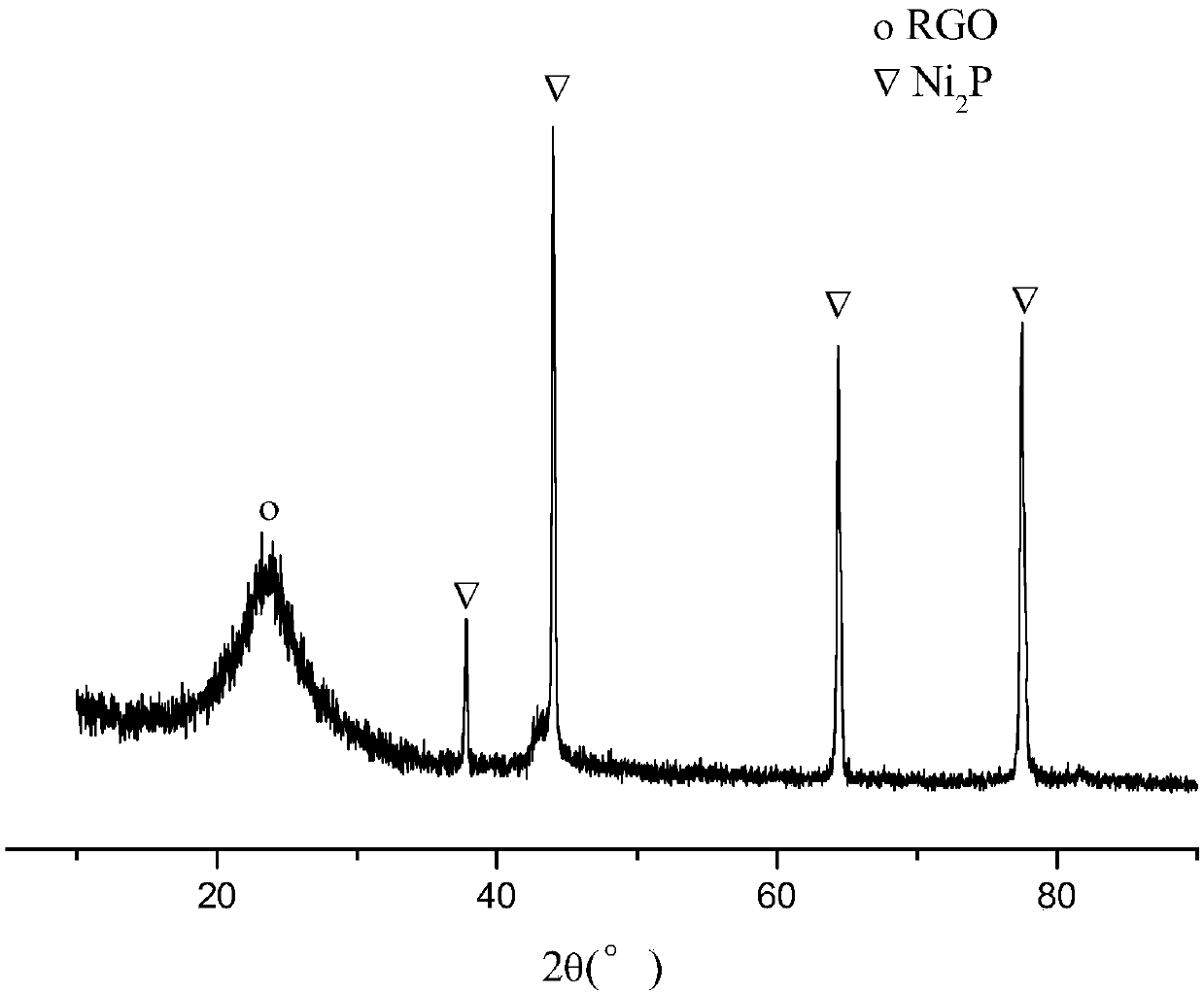

[0022] In terms of catalyst, according to Ni 2 The load of P is 20%, and the molar ratio of Ni element and P element is 2:1.5, add 1.0g graphene oxide into 500mL containing 1.1409g (4.80mmol) NiCl 2 ·6H 2 O and 0.3815g (3.60mmol) NaH 2 PO 2 ·H 2 In the mixed aqueous solution of O, ultrasonically disperse at room temperature for 2 hours, then add 2 mL (32.98 mmol) of hydrazine hydrate aqueous solution with a volume fraction of 80% at 80 ° C, react at constant temperature for 4 hours, filter with suction, and wash the filter cake repeatedly with deionized water , transferred to a vacuum drying oven at 60°C to fully dry, and finally baked at 300°C for 4 hours in a nitrogen atmosphere to obtain Ni 2 P / RGO catalyst with a specific surface area of 181.9m 2 g -1 , the average pore diameter is 12.2nm, the pore volume is 0.55cm 3 g -1 . Depend on figure 1 It can be seen that Ni appears at 37.6°, 43.9°, 64.2°, 77.4° 2 The typical diffraction peak of P indicates that the pre...

Embodiment 2

[0024] In terms of catalyst, according to Ni 2 The load of P is 10%, and the molar ratio of Ni element and P element is 2:1.5, add 1.0g graphene oxide into 500mL containing 0.5705g (2.40mmol) NiCl 2 ·6H2 O and 0.1908g (1.80mmol) NaH 2 PO 2 ·H 2 In the mixed aqueous solution of O, ultrasonically disperse at room temperature for 2 hours, then add 2 mL (32.98 mmol) of hydrazine hydrate aqueous solution with a volume fraction of 80% at 80 ° C, react at constant temperature for 4 hours, filter with suction, and wash the filter cake repeatedly with deionized water , transferred to a vacuum drying oven at 60°C to fully dry, and finally baked at 300°C for 4 hours in a nitrogen atmosphere to obtain Ni 2 P / RGO catalyst with a specific surface area of 197.4m 2 g -1 , with an average pore diameter of 10.6nm and a pore volume of 0.61cm 3 g -1 .

Embodiment 3

[0026] In terms of catalyst, according to Ni 2 The load of P is 15%, and the molar ratio of Ni element and P element is 2:1.5, add 1.0g graphene oxide into 500mL containing 0.8567g (3.60mmol) NiCl 2 ·6H 2 O and 0.2861g (2.70mmol) NaH 2 PO 2 ·H 2 In the mixed aqueous solution of O, ultrasonically disperse at room temperature for 2 hours, then add 2 mL (32.98 mmol) of hydrazine hydrate aqueous solution with a volume fraction of 80% at 80 ° C, react at constant temperature for 4 hours, filter with suction, and wash the filter cake repeatedly with deionized water , transferred to a vacuum drying oven at 60°C to fully dry, and finally baked at 300°C for 4 hours in a nitrogen atmosphere to obtain Ni 2 P / RGO catalyst with a specific surface area of 188.2m 2 g -1 , the average pore diameter is 11.5nm, the pore volume is 0.54cm 3 g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com