Low-viscosity skin lotion and preparation method thereof

A technology of skin care milk and low viscosity, which is applied in the field of low viscosity skin care lotion and the manufacture of the low viscosity skin care lotion. It can solve the problems of complex equipment, large changes in the viscosity and temperature of the lotion, and the inability to pour it out, and achieve the effect of simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the above low-viscosity skin care emulsion comprises the following sequential steps: first calculate by weight percentage, weigh each component according to the formula; Add it into the oil phase pot and heat up to 90°C-95°C; add stabilizers, some preservatives, deionized water and other water-soluble components into the water phase pot and heat up to 90°C-95°C; then put the oil phase pot The raw materials and water phase pot raw materials are vacuum pumped into the emulsification pot, homogenized for 5-15 minutes, and the homogenization speed is 2200-3400r / min, then the emulsion is cooled, the remaining components are added, continued cooling, and discharged. Emphasis of the present invention is the selection of emulsifying agent and the selection of stabilizing agent, will make low-viscosity emulsion stable, the key is to use multiple non-ionic emulsifying agent pairs and multiple polymers and macromolecular polysaccharides as stabilizing agen...

Embodiment 1

[0036] Oil phase raw materials:

[0037]

[0038] Water Phase Raw Materials:

[0039]

[0040] Preparation:

[0041] First weigh each component according to the above formula, and then put ① into Add all the ingredients into the oil phase pot, heat up to 90°C-95°C, put Put the ingredients into the water phase pot, heat up to 90°C-95°C, then vacuum pump the oil phase pot raw materials and water phase pot raw materials into the emulsification pot, homogenize for 10 minutes, and the homogenization speed is 2800r / min, then cool the liquid to 45°C, add Continue to cool the liquid to 40°C, then it can be discharged from the emulsification pot.

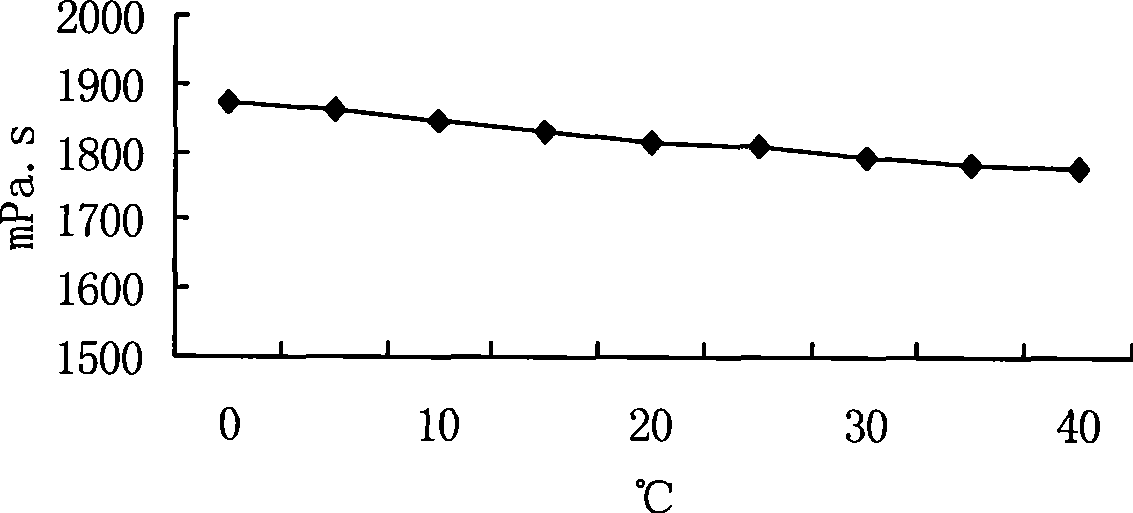

[0042] Detection: Measure the viscosity of the emulsion with a BROOKFIELD viscometer at room temperature 25°C. The viscosity of the emulsion is 1809mPa.s. After the emulsion is kept at a temperature of 38±1°C for 1 hour, it is centrifuged in a centrifuge at a speed of 2000r / min for 30 minutes. The emulsion is stable. layered. ...

Embodiment 2

[0046] Oil phase raw materials:

[0047]

[0048] Water Phase Raw Materials:

[0049]

[0050]

[0051] Preparation:

[0052] First weigh each component according to the above formula, and then put ① into Add all the ingredients into the oil phase pot, heat up to 90°C-95°C, put Put the ingredients into the water phase pot, heat up to 90°C-95°C, then vacuum pump the oil phase pot raw materials and water phase pot raw materials into the emulsification pot, homogenize for 10 minutes, and the homogenization speed is 2800r / min, then cool the liquid to 45°C, add Continue to cool the liquid to 40 ° C, that is, it can be discharged from the emulsification pot.

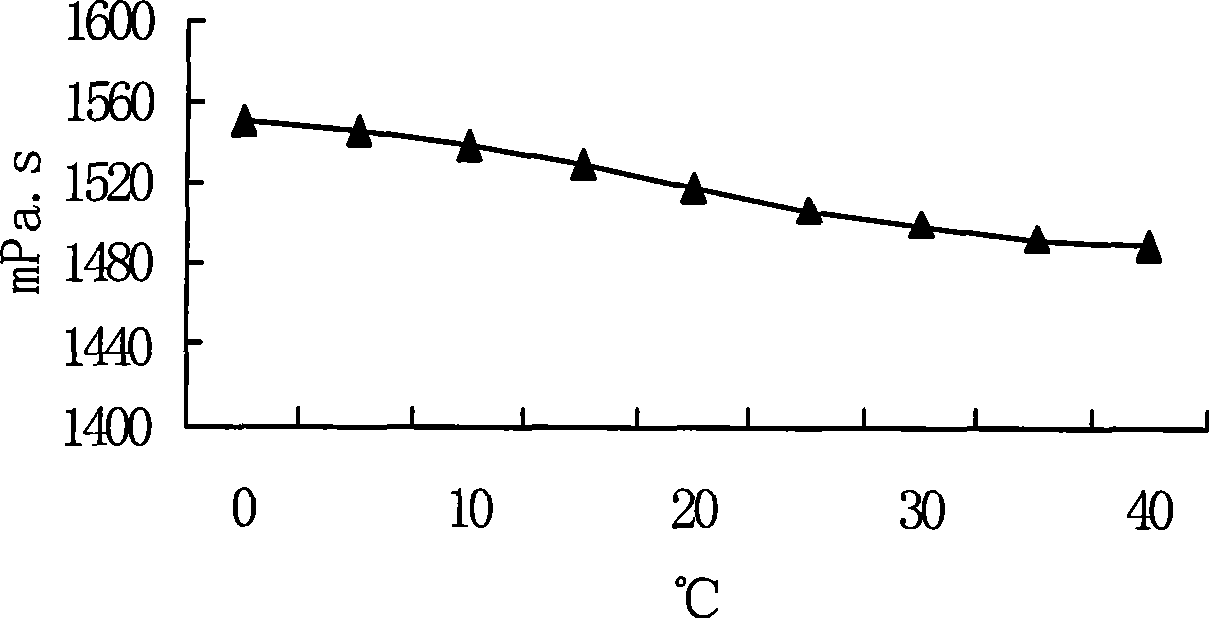

[0053] Detection: Measure the viscosity of the emulsion with a BROOKFIELD viscometer at room temperature 25°C. The viscosity of the emulsion is 1507mPa.s. After the emulsion is kept at a constant temperature of 38±1°C for 1 hour, it is centrifuged in a centrifuge at a speed of 2000r / min for 30 minutes. The emul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com