Two-section type tobacco stem microwave expansion processing method

A technology of microwave expansion and treatment method, which is applied in the field of tobacco processing, can solve the problems affecting the filament rate, yield and quality of cut stems, and achieve the goal of improving the filament rate and yield, good uniformity, and uniform moisture and temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

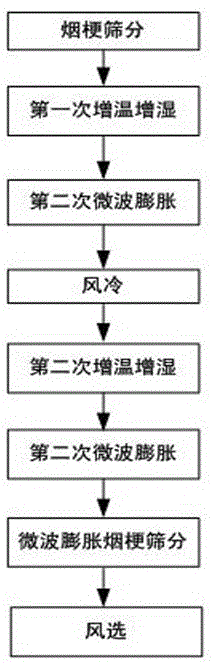

Method used

Image

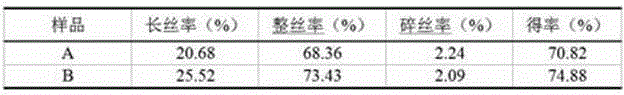

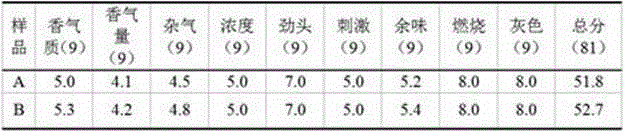

Examples

Embodiment 1

[0029] (1) Tobacco stem screening: Screen the upper stem to be expanded through a 5mm×25mm waist-shaped vibrating screen to improve the uniformity of tobacco stem expansion;

[0030] (2) First temperature increase and humidification: use 190°C steam to carry out the first temperature increase and humidification treatment on the tobacco stem sieve obtained in step (1), so that the surface temperature of the tobacco stem is 65.9°C, and the tobacco stem Stem moisture is 13.35wt%;

[0031] (3) The first microwave expansion: transport the tobacco stem obtained in step (2) to a drum-type microwave expansion equipment under the conditions of a microwave power of 25.5KW, an inclination angle of the microwave expansion equipment of 7°, and a rotation speed of 5.0r / min Under expand, make the average expansion rate of tobacco stem 89%, tobacco stem moisture is 8.75wt%;

[0032] (4) Air cooling: the tobacco stems obtained in step (3) are forced to air-cool for 75 seconds, so that the sur...

Embodiment 2

[0038] (1) Tobacco stem screening: Screen the middle stem to be expanded through a 5mm×25mm waist-shaped hole screen to improve the uniformity of tobacco stem expansion;

[0039] (2) The first temperature increase and humidification: use 185°C steam to carry out the first temperature increase and humidification treatment on the tobacco stem sieved obtained in step (1), so that the surface temperature of the tobacco stem is 80°C, and the tobacco stem surface temperature is 80°C. Stem moisture is 12wt%;

[0040] (3) The first microwave expansion: transport the tobacco stem obtained in step (2) to a drum-type microwave expansion equipment, under the conditions of a microwave power of 26KW, an inclination angle of the microwave expansion equipment of 7°, and a rotation speed of 5.2r / min Carry out expansion, make the average expansion rate of tobacco stem 100%, tobacco stem moisture is 9.28wt%;

[0041] (4) Air cooling: the tobacco stems obtained in step (3) are subjected to force...

Embodiment 3

[0047] (1) Tobacco stem screening: Screen the lower stem to be expanded through a 5mm×25mm waist-shaped hole screen to improve the uniformity of tobacco stem expansion;

[0048] (2) The first temperature increase and humidification: use 180°C steam to carry out the first temperature increase and humidification treatment on the tobacco stem sieve obtained in step (1), so that the surface temperature of the tobacco stem is 60°C, and the tobacco stem surface temperature is 60°C. Stem moisture is 14wt%;

[0049] (3) The first microwave expansion: transport the tobacco stems obtained in step (2) to a drum-type microwave expansion equipment under the conditions of a microwave power of 24KW, an inclination angle of the microwave expansion equipment of 7°, and a rotation speed of 5.5r / min Carry out expansion, make the average expansion rate of tobacco stem 80%, tobacco stem moisture is 8wt%;

[0050] (4) Air-cooling: the tobacco stems obtained in step (3) are subjected to forced air-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com