System and method for detecting eccentricity of glasses lens

A technology of eccentricity detection and lens, which is applied in determining the position of the lens, testing optical performance, optics, etc., can solve problems such as easy to generate errors, difficult to accurately determine the geometric central axis, and inaccurate eccentricity measurement results, etc., to achieve accurate detection results and improve The effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings.

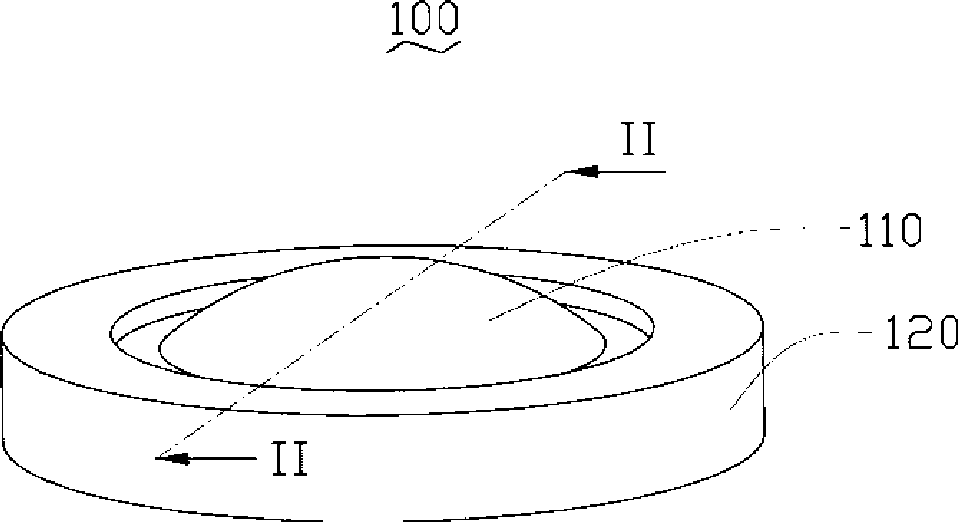

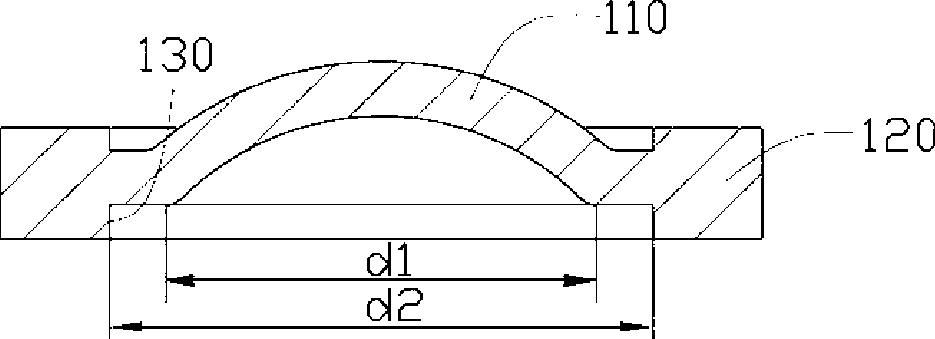

[0018] see figure 1 and figure 2 , the lens 100 to be inspected in this embodiment is an embedded lens, which may be a spherical mirror or an aspherical mirror. The lens to be inspected 100 includes a main body 110 and a peripheral portion 120 surrounding the main body 110 . The main body 110 is the part of the lens that plays an optical role, and the main body 110 can be configured in a concave or convex shape according to specific needs, so as to diverge or converge light. The peripheral part 120 is annular, surrounds and connects the main part 110, and is mainly used to place and support adjacent components. The inner diameter of the main part 110 is d1 and the outer diameter is d2. The peripheral portion 120 has an inner wall 130 .

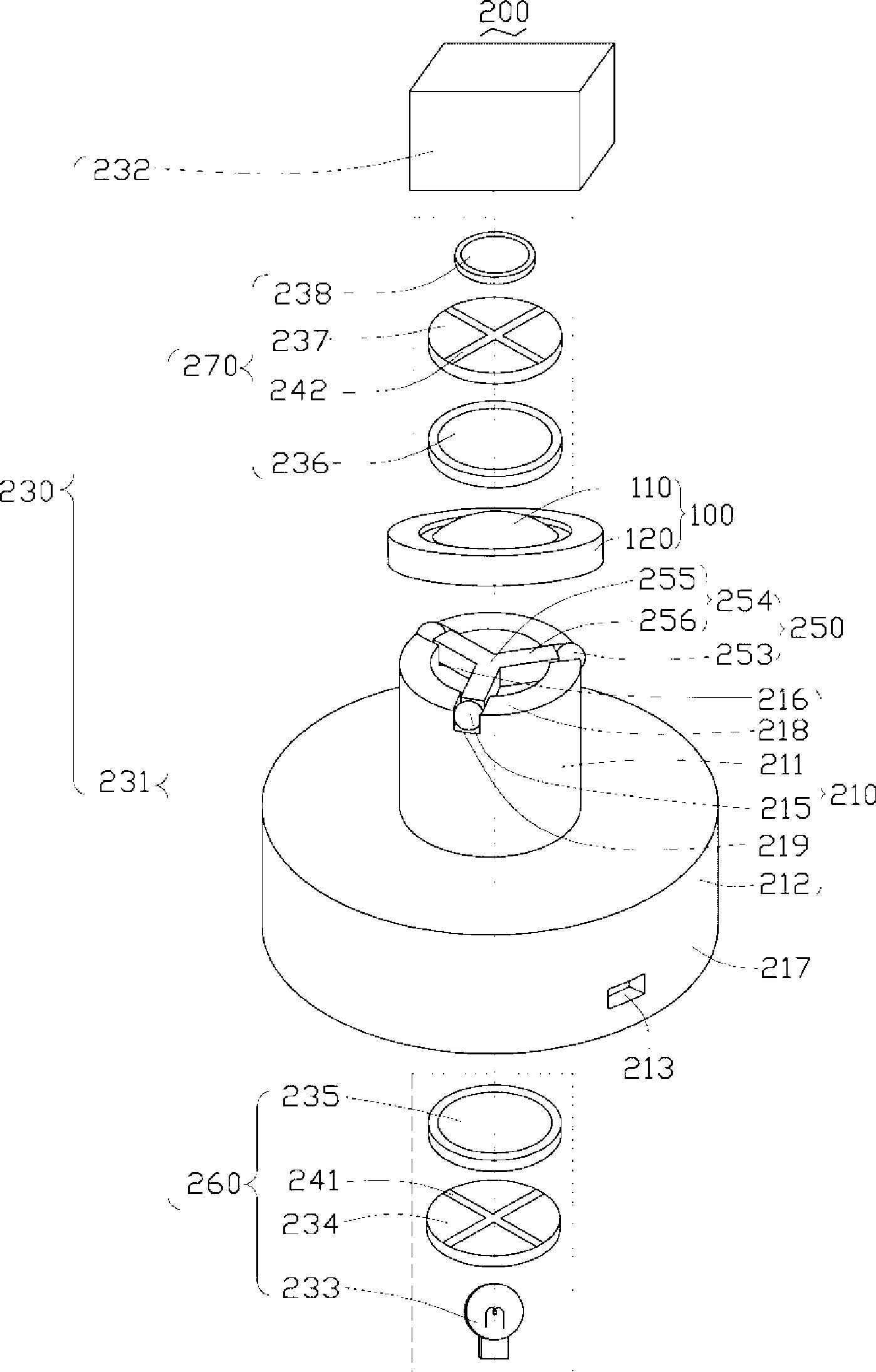

[0019] see image 3 and Figure 4 , The lens eccentricity detection system 200 provided in this embodiment includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com