Forming device of rapid heating and cooling separation type continuous carbon fiber thermoplastic U-shaped part and process

A technology of cooling separation and rapid heating, applied in the field of molding devices, can solve the problems of poor product surface quality, high equipment requirements, and high energy consumption, and achieve the effects of facilitating rapid heating, increasing heat exchange area, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be described in further detail below through specific embodiments.

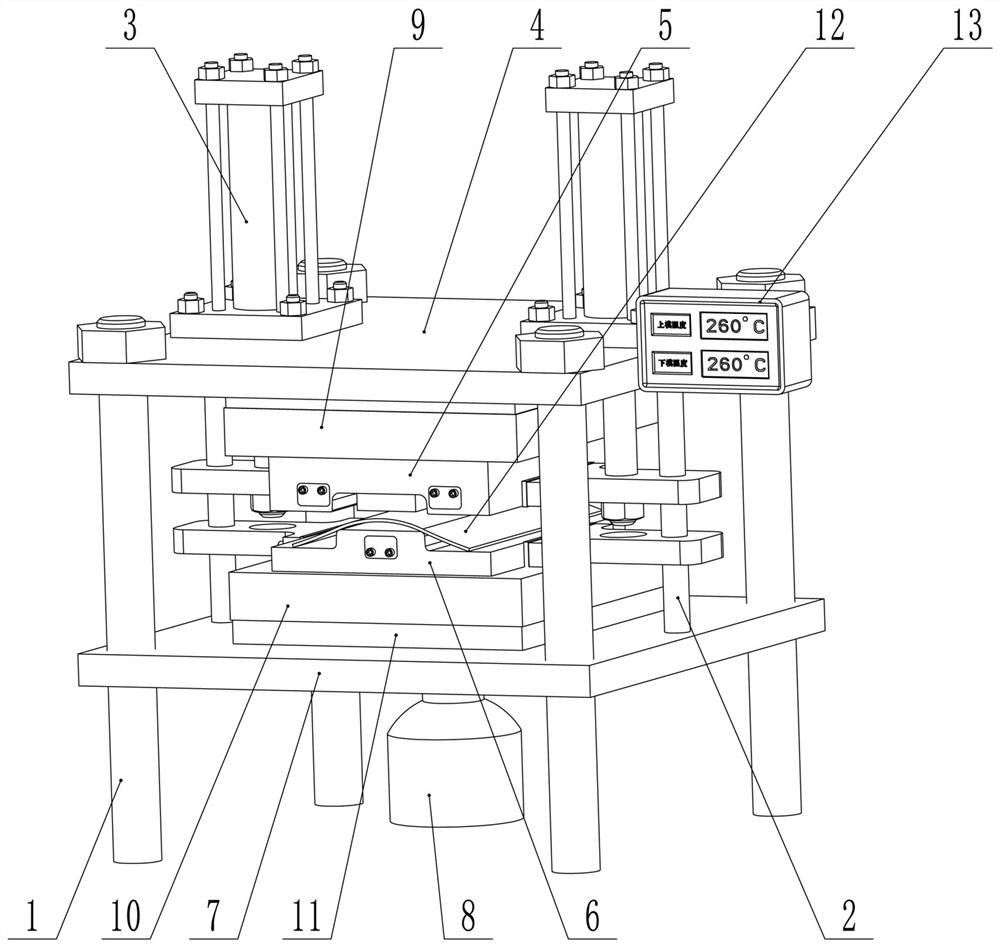

[0038] Such as Figure 1 to Figure 4As shown, a rapid heating and cooling separation type continuous carbon fiber thermoplastic U-shaped part forming device includes an upper drive mechanism, a lower drive mechanism, four Green columns 1, two vertical slide bars 2 and sequentially arranged from top to bottom The upper base, the upper mold 5, the lower mold 6 and the lower base corresponding to the upper mold 5, the bottom of the upper base is provided with an upper heating plate 9, and the top of the lower base is provided with a lower heating plate 10, Both the upper mold 5 and the lower mold 6 are embedded with a cooling mechanism; the two ends of the upper mold 5 and the lower mold 6 are respectively sleeved on the two vertical slide bars 2 , the upper drive mechanism drives the upper mold 5 up and down, the lower mold 6 is provided with a minim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com