Fixture for testing tensile mechanical properties of non-metallic material at 500K-4.2K

A technology of non-metallic materials and tensile properties, applied in the direction of analyzing materials, measuring devices, scientific instruments, etc., can solve the problems that the mechanical tensile test data is not too comparable, and it is not easy to obtain reliable comparison data, etc., to achieve Good orientation, easy installation, firm clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

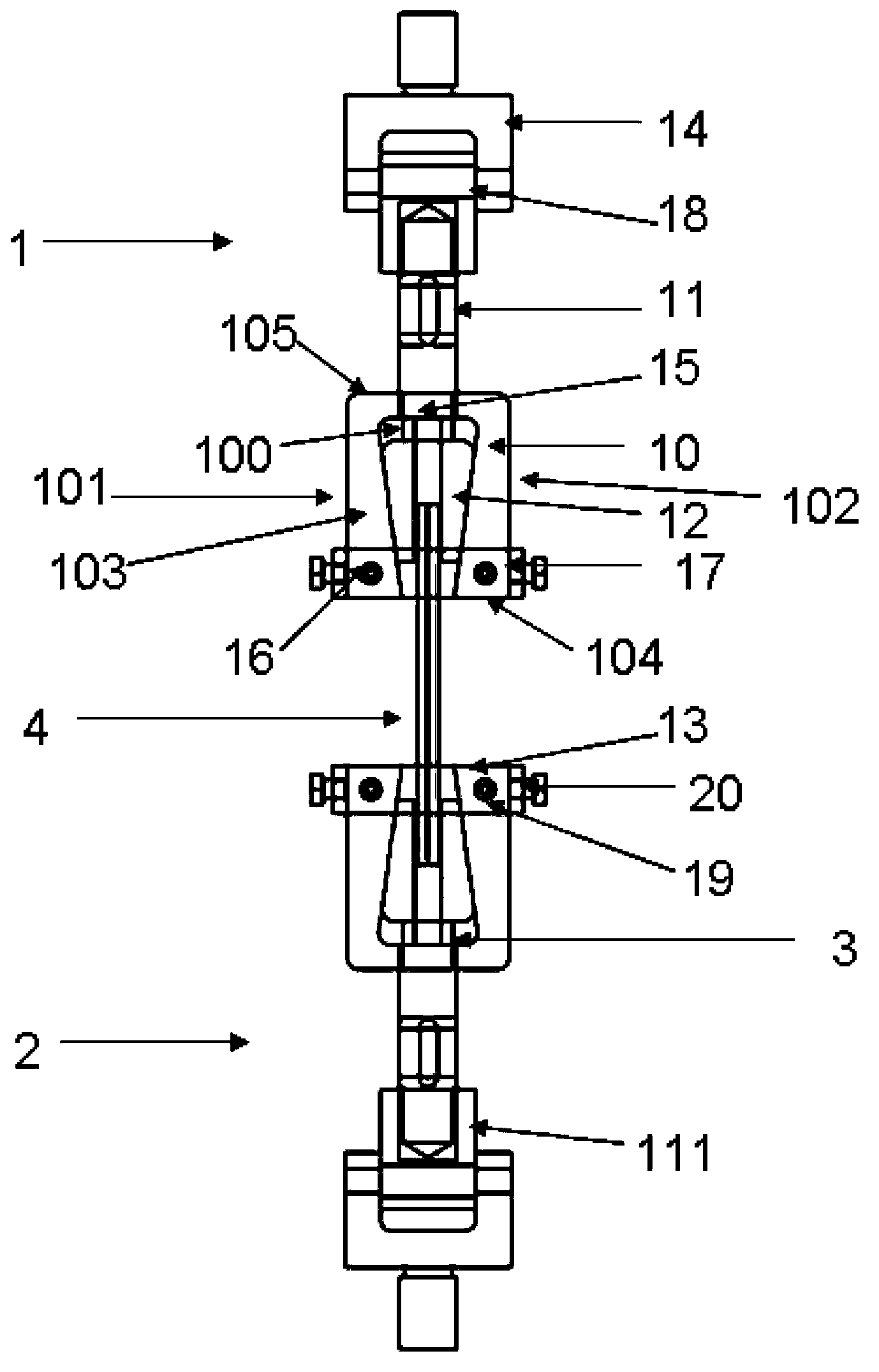

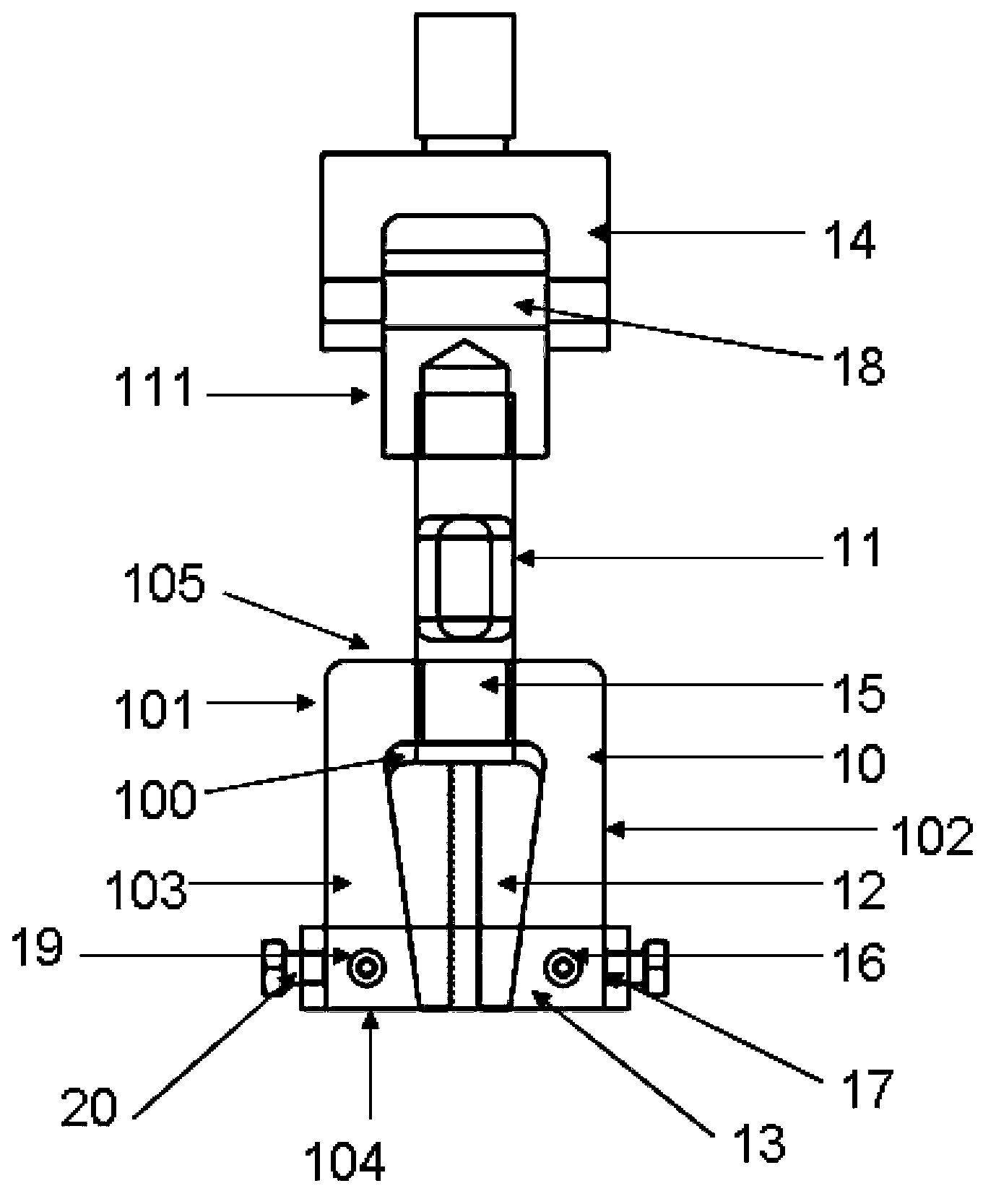

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] figure 1 is a schematic structural diagram of the present invention; figure 2 It is a schematic structural diagram of the upper chuck (or lower chuck); figure 1 It can be seen that the test fixture for the mechanical tensile properties of non-metallic materials at 500K ~ 4.2K provided by the present invention is composed of an upper chuck and a lower chuck, and the shape and structure of the upper chuck and the lower chuck are exactly the same and placed opposite to each other. ;

[0018] Take the above chuck 1 as an example, the structure of the upper chuck 1 is as follows:

[0019] The upper chuck 1 is composed of an upper chuck main body 10, an upper bearing rod 11, an upper tooth element 12, an upper frame-shaped reinforcement groove 13 and an upper adapter 14;

[0020] The shape of the upper chuck main body 10 is a cuboid shape, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com