Device and method for detecting optical-axis offset of lens in equipment

A technology of optical axis offset and detection equipment, applied in the field of optical detection, to achieve the effect of simple and easy detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

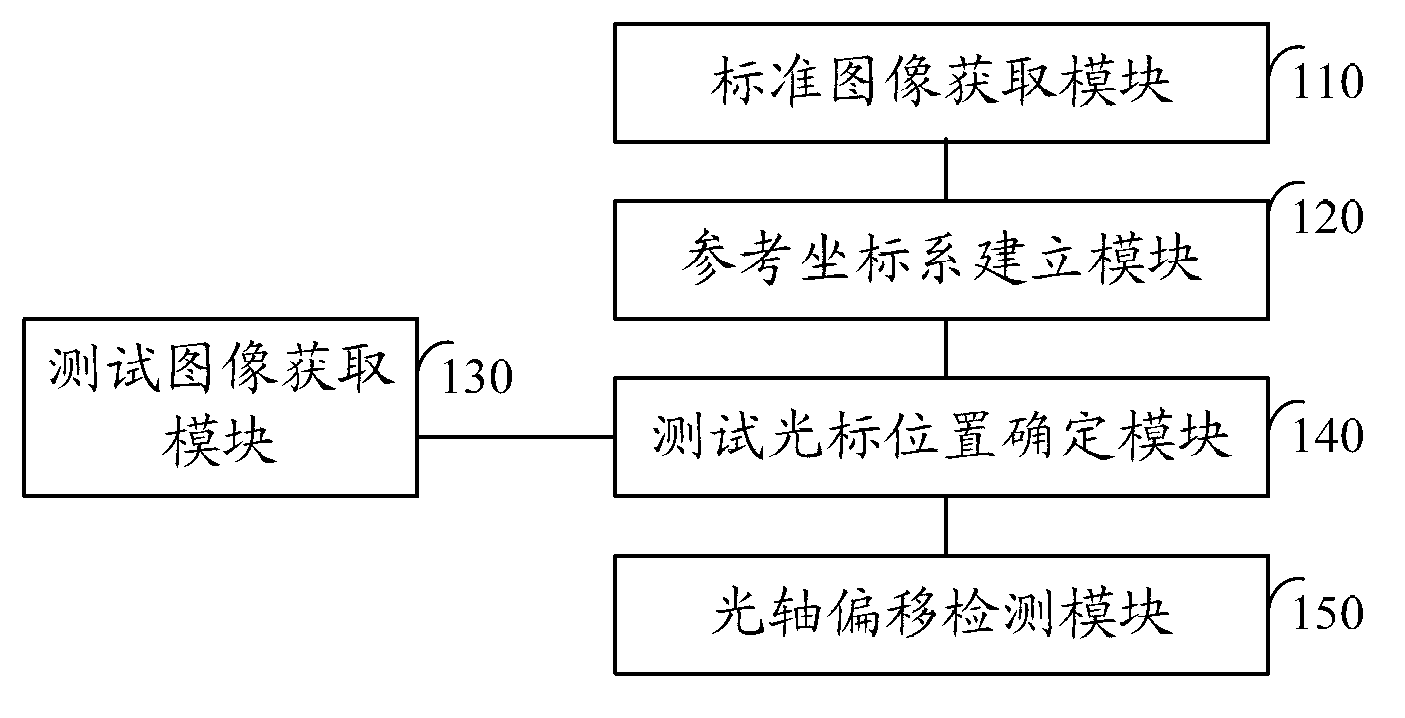

[0046] see figure 1 , is a structural diagram of the device for detecting the optical axis deviation of the lens in the device in an embodiment provided by the present invention. The device includes: a standard image acquisition module 110 , a reference coordinate system establishment module 120 , a test image acquisition module 130 , a test cursor position determination module 140 and an optical axis offset detection module 150 .

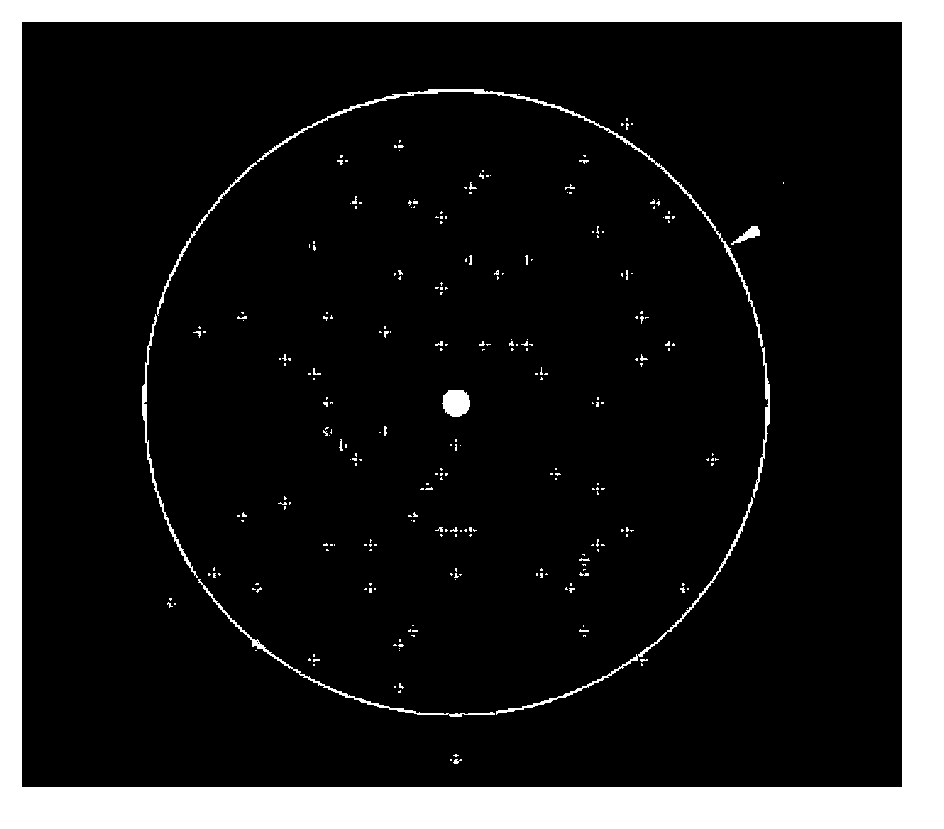

[0047] The standard image acquiring module 110 is configured to take a picture sample after focusing the standard lens assembled in the device at the shooting position, and obtain a standard image of the picture sample.

[0048] Wherein, the standard lens is a lens whose determined optical axis offset is w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com