Eccentricity adjusting and assembling method, and eccentricity adjusting and assembling device of optical element

An optical element, eccentric adjustment technology, applied in optical elements, optical devices, optics, etc., can solve the problem of no established method, etc., and achieve the effect of effective measurement and high-precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

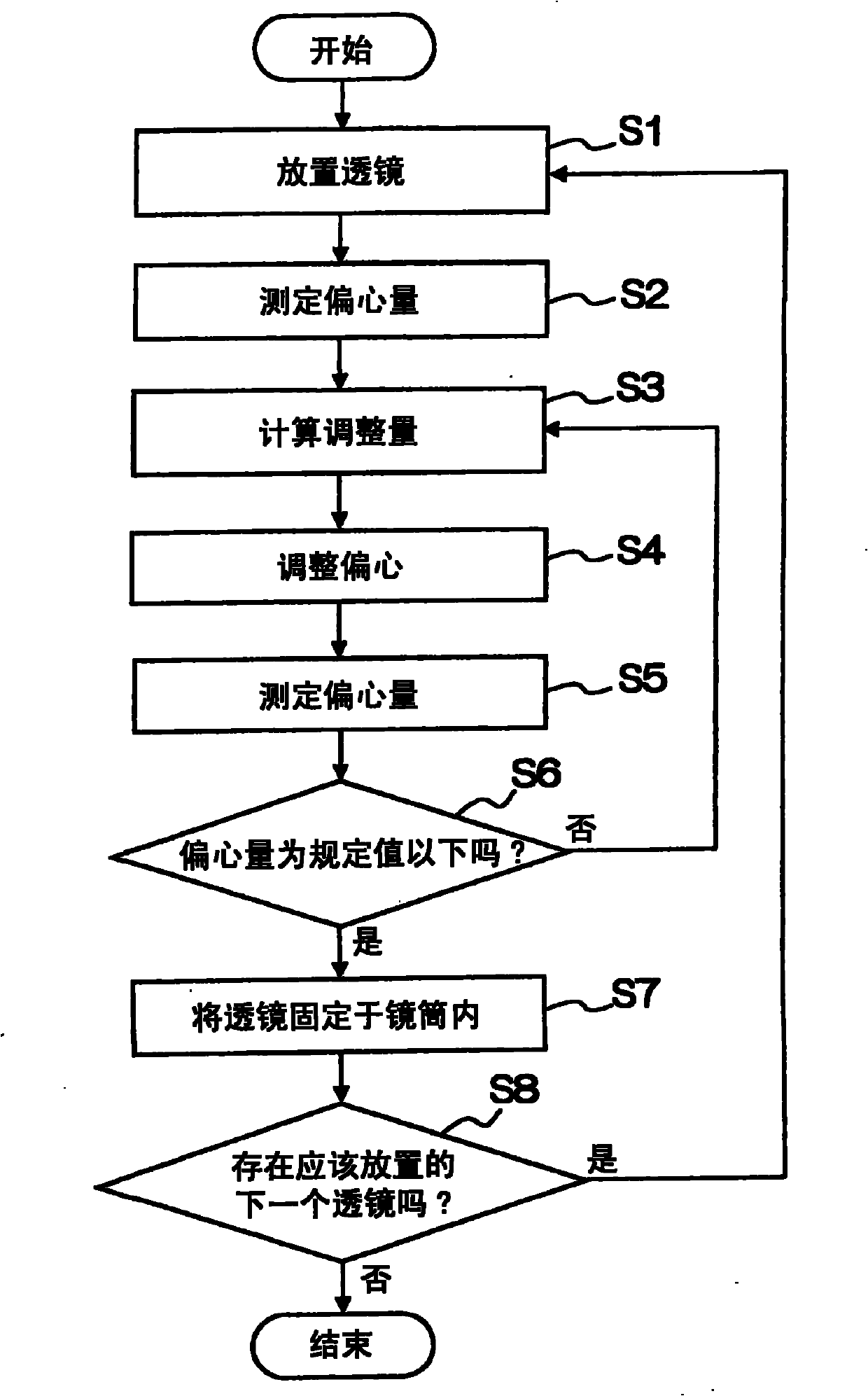

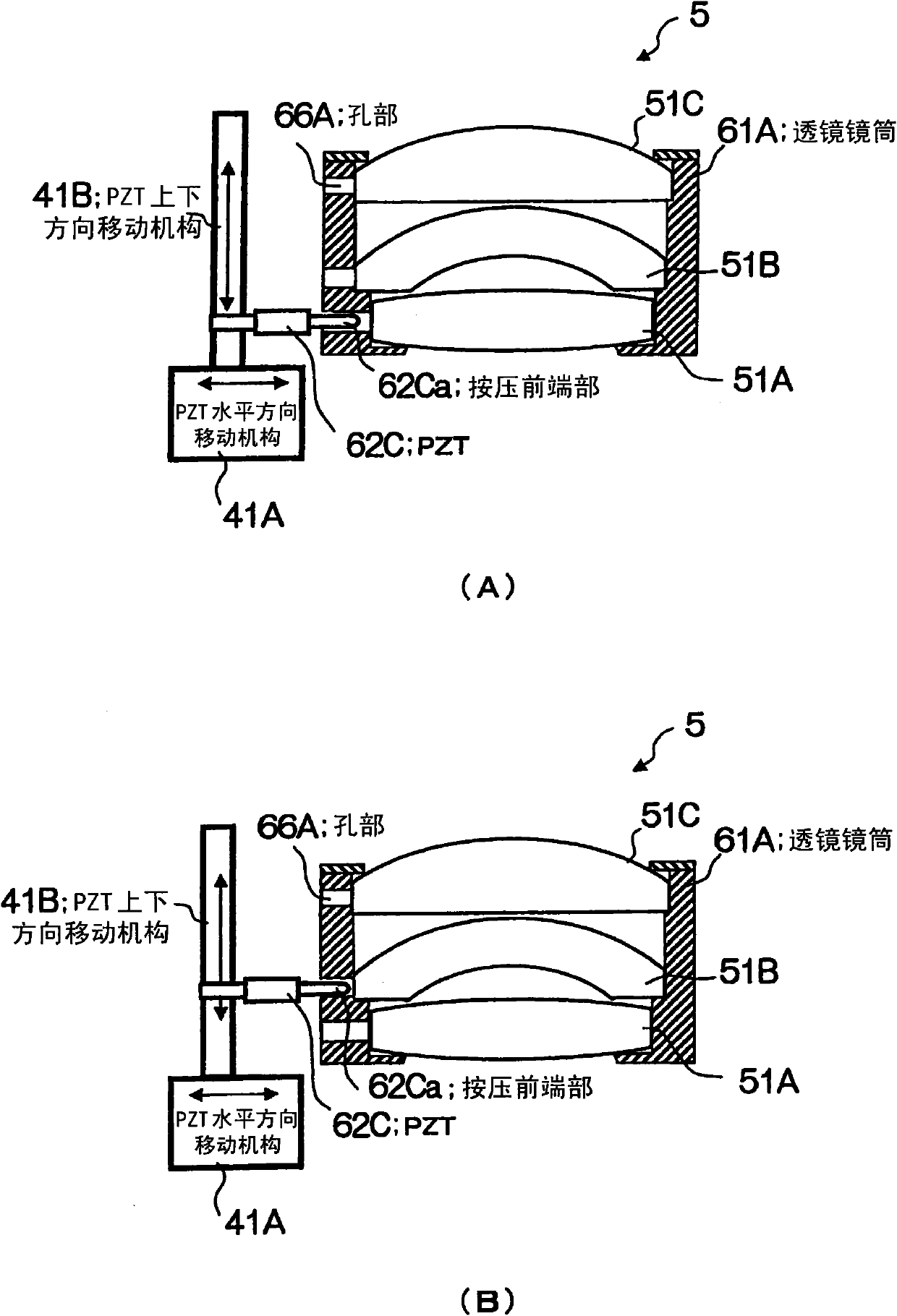

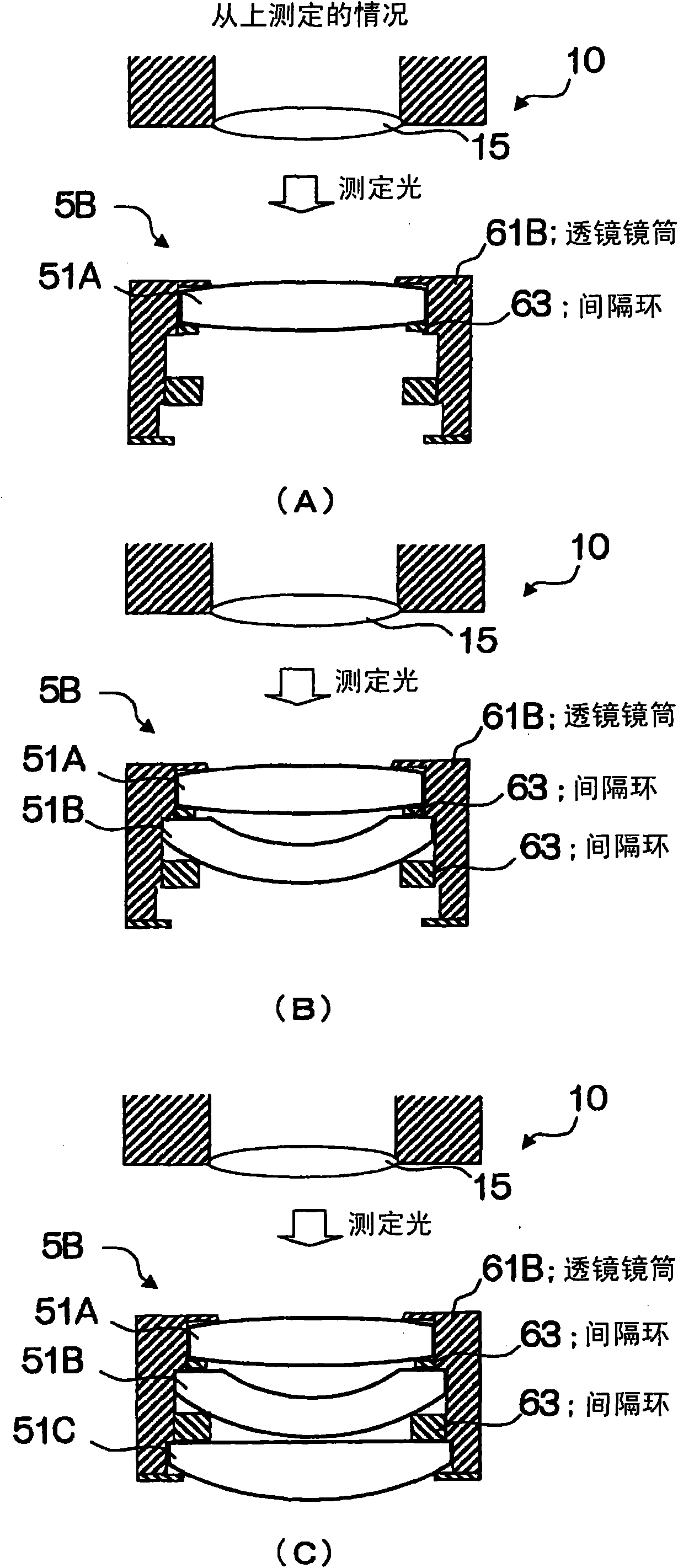

[0039] Hereinafter, embodiments according to the present invention will be described in detail with reference to the drawings. figure 2 It is a schematic block diagram of the apparatus used for the eccentricity adjustment assembly method of the optical element which concerns on one Embodiment of this invention.

[0040] That is, the eccentricity adjustment assembly device 1 measures the eccentricity of each inspected lens of the inspected lens assembly 5, and adjusts the measured eccentricity to be substantially 0. In this state, it has the following configuration: a measuring head 10, a rotatable A base 20 for holding the lens assembly 5 under inspection, an analysis operation unit 30 for performing various calculations for calculating eccentricity, and a Z-axis stage 40 for holding the measuring head 10 movably in the vertical direction in the figure.

[0041] The measuring head 10 includes: a light source 11 that outputs a light beam that is irradiated on the above-mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com