Lens shift measuring apparatus, lens shift measuring method, and optical module manufacturing method

A technology for measuring equipment and offset, applied in the direction of testing optical performance, optics, measuring devices, etc., can solve problems such as optical axis or optical module optical coupling efficiency reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

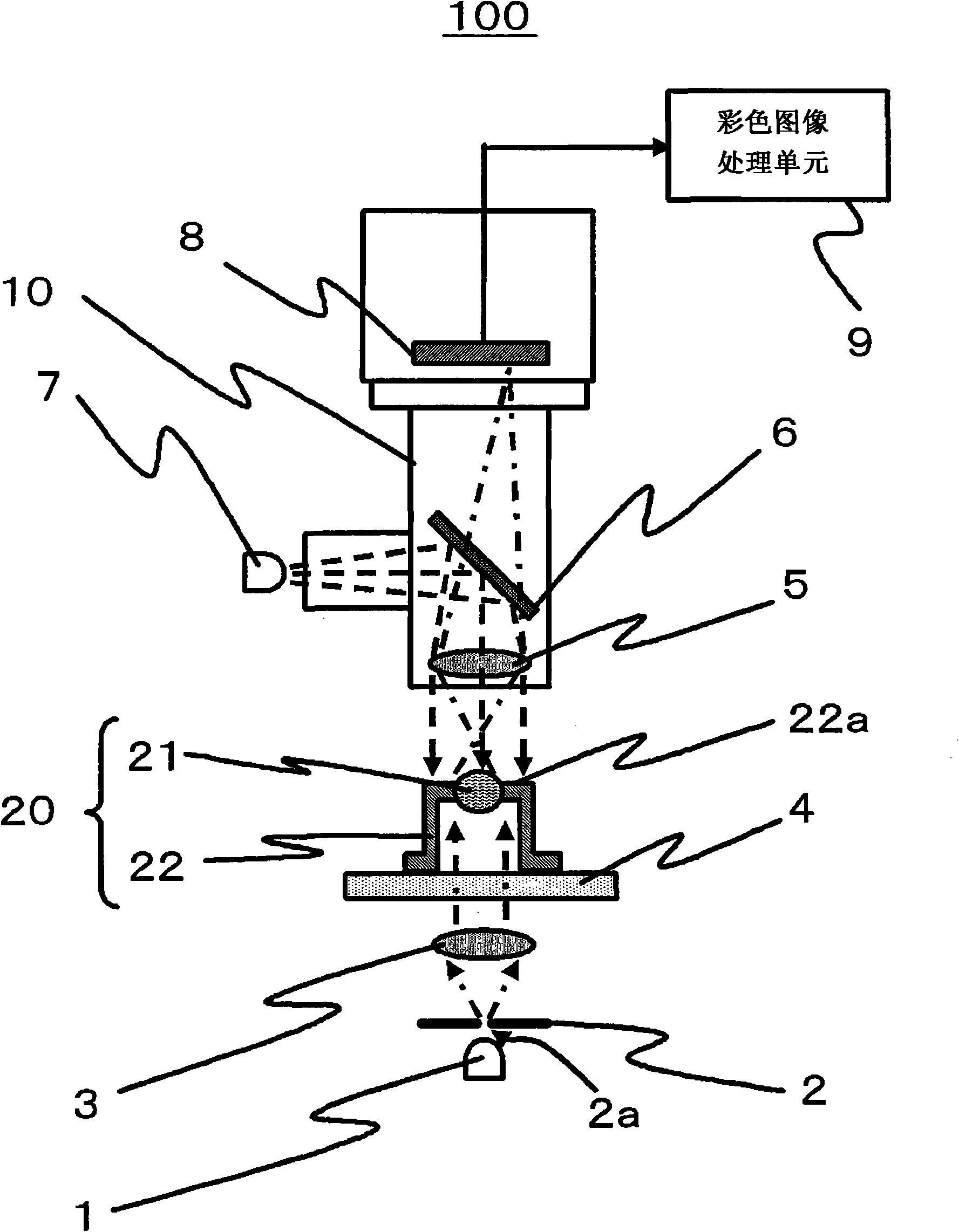

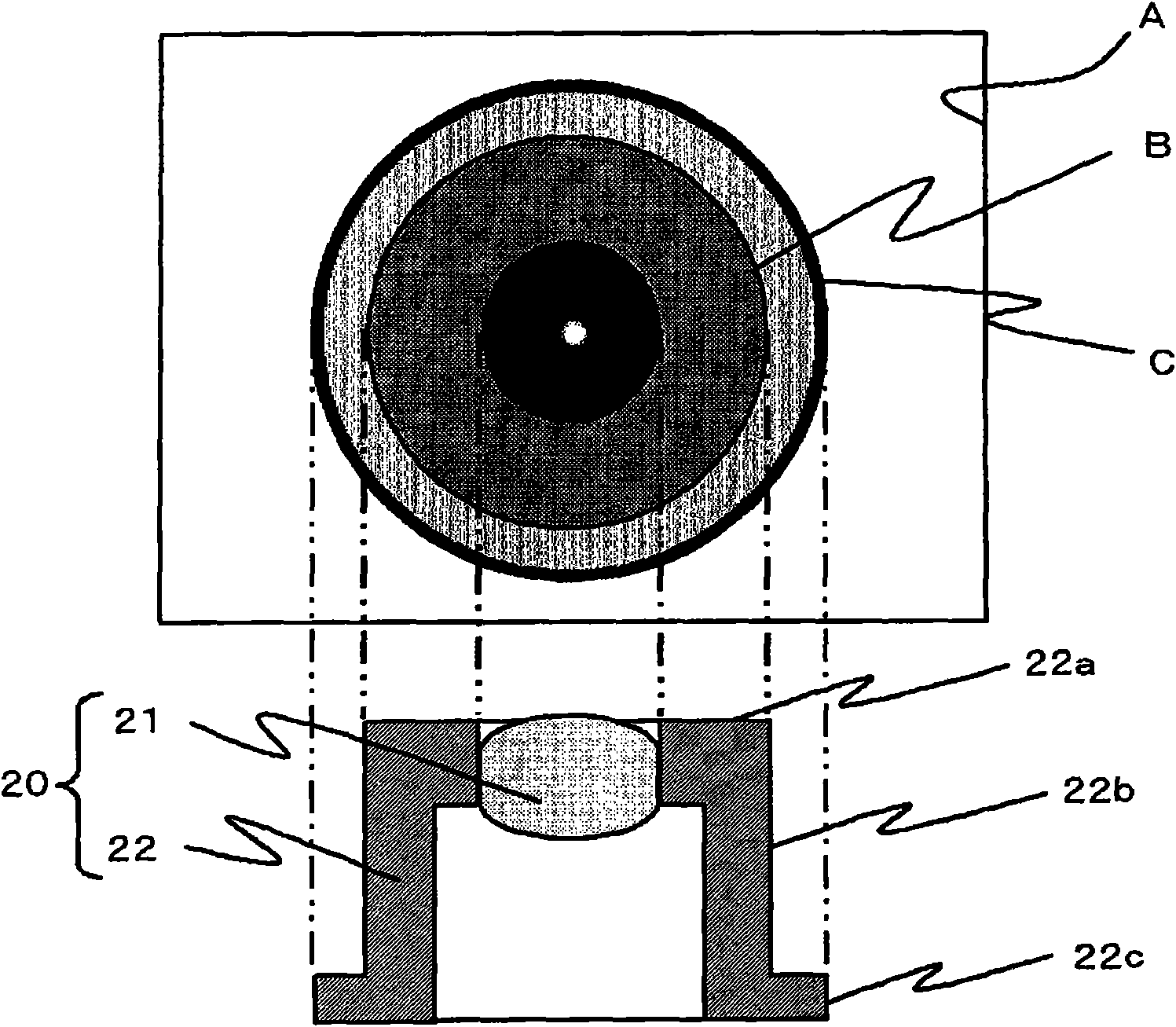

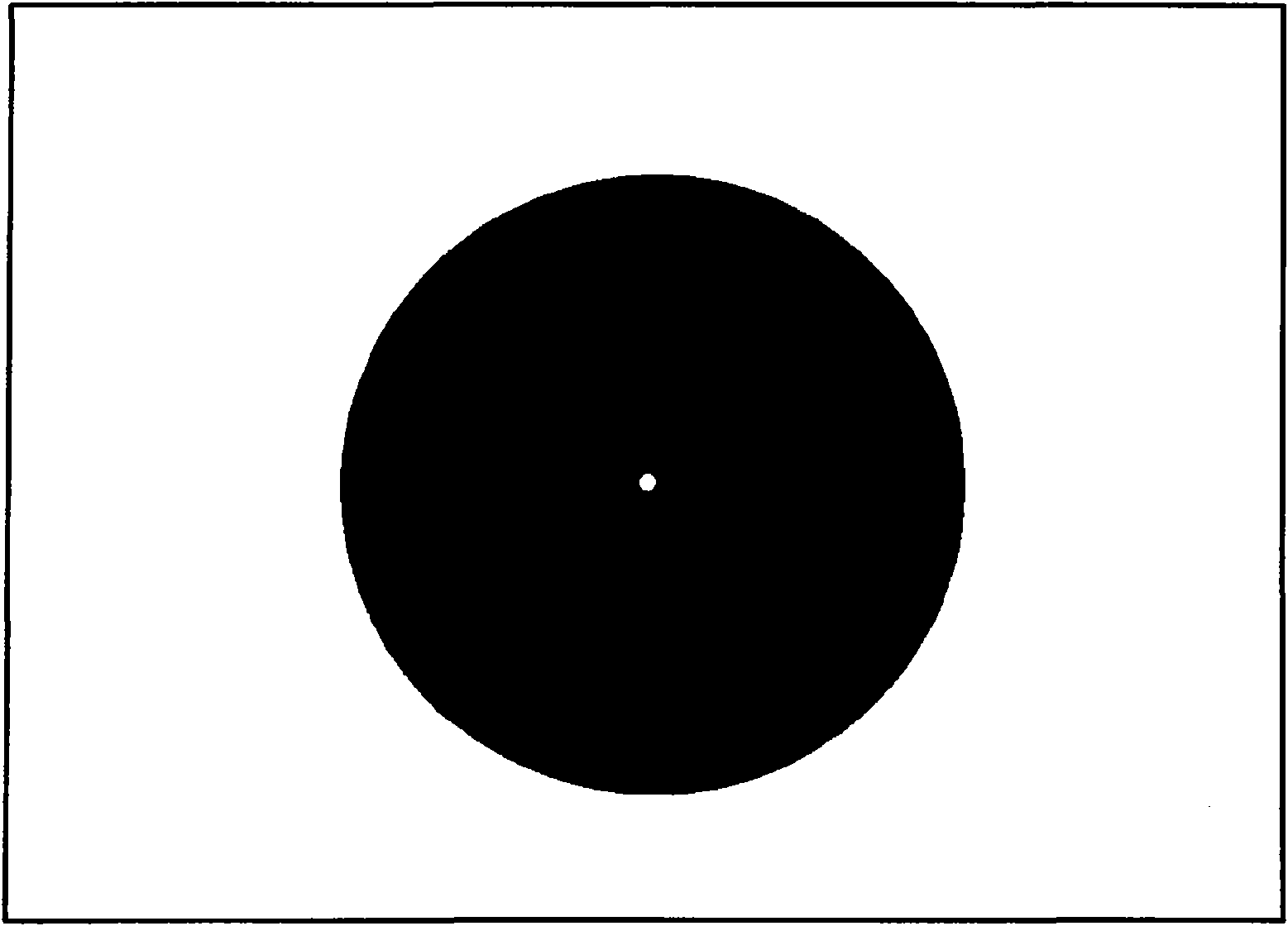

[0038] figure 1 is a schematic front cross-sectional view of the lens shift measuring apparatus 100 according to the first embodiment. Figure 5 is a flowchart showing the operation flow of the lens shift measuring method according to the first embodiment. Figure 9 is a schematic cross-sectional view showing an example of the optical module 150 manufactured by the optical module manufacturing method according to the first embodiment.

[0039] The lens shift measuring apparatus 100 according to this embodiment includes a radiation unit (for example, configured to irradiate epi-illumination light using epi-illumination light source 7 and to irradiate transmitted illumination light using trans-illumination light source 1 ), which radiates light to an attached On the lens member (for example, lens cover 20), the lens-attached member has a lens 21 and a frame (for example, cover 22) to hold the lens 21, thereby generating reflected light from the frame and passing through it by f...

no. 2 example

[0129] Figure 10 is a schematic front cross-sectional view of the lens shift measuring apparatus 200 according to the second embodiment. Figure 11 is a flowchart showing the flow of operations of the lens shift measuring method according to this second embodiment.

[0130] In the first embodiment, description has been made on an example of the case where the wavelengths of the epi-illumination light and the transmission illumination light are set to be different from each other, and an image of the color of the epi-illumination light is extracted from a color image obtained by one imaging and images of the color of the transmitted illumination light, and perform image processing separately. Meanwhile, in the second embodiment, an example of a case where imaging based on epi-illumination light and imaging based on transmitted illumination light are performed at different timings will be described.

[0131] In the case of this embodiment, the wavelengths of the epi-illuminat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com