Elevator lift car rope end installing structure

A rope head installation, elevator car technology, applied in the direction of transportation and packaging, elevators, etc., can solve the problems of high civil construction costs, cumbersome installation process, low installation accuracy, etc., to achieve reduced construction costs, simple structure, relative positional relationship precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

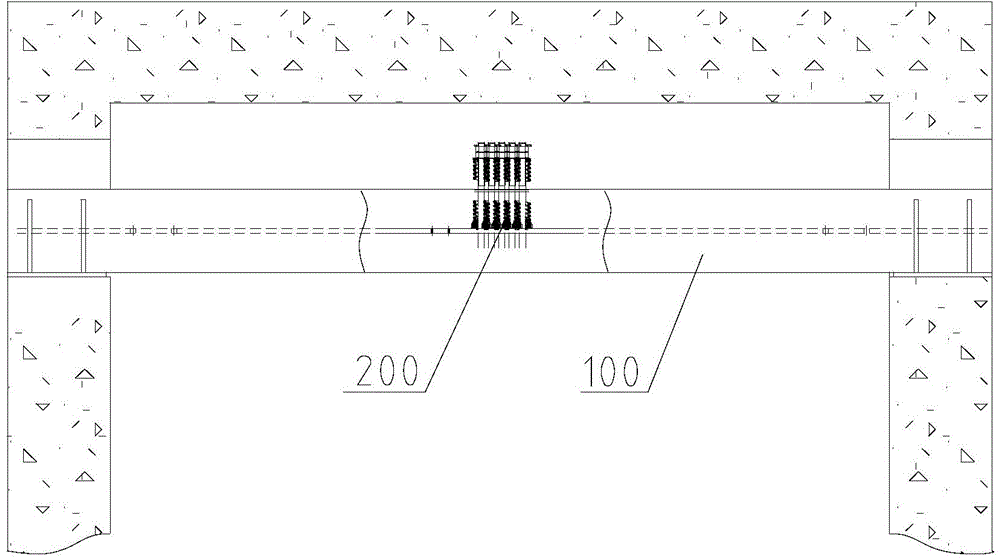

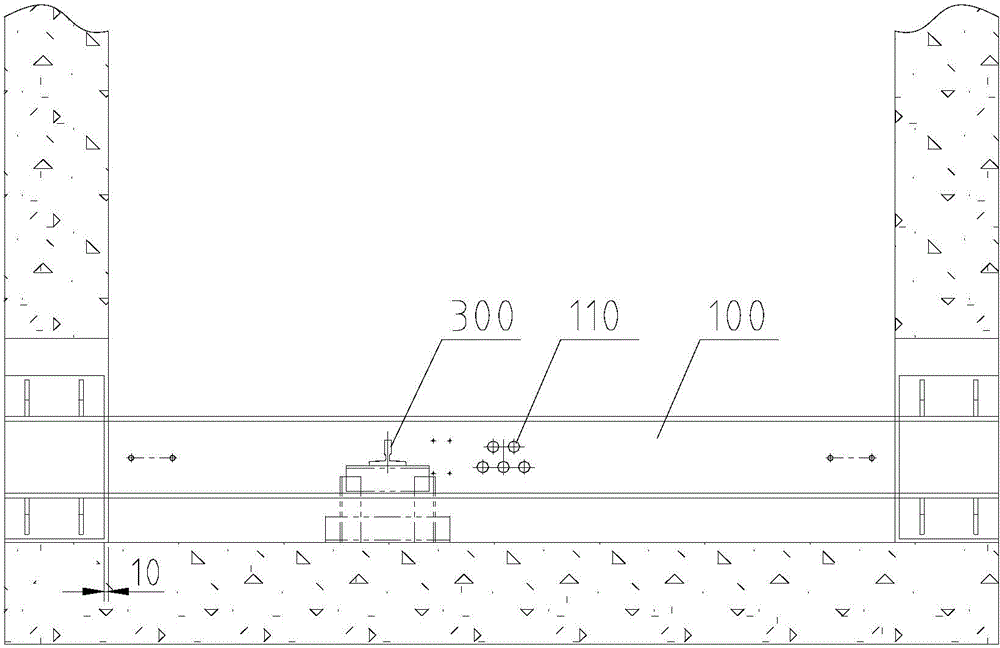

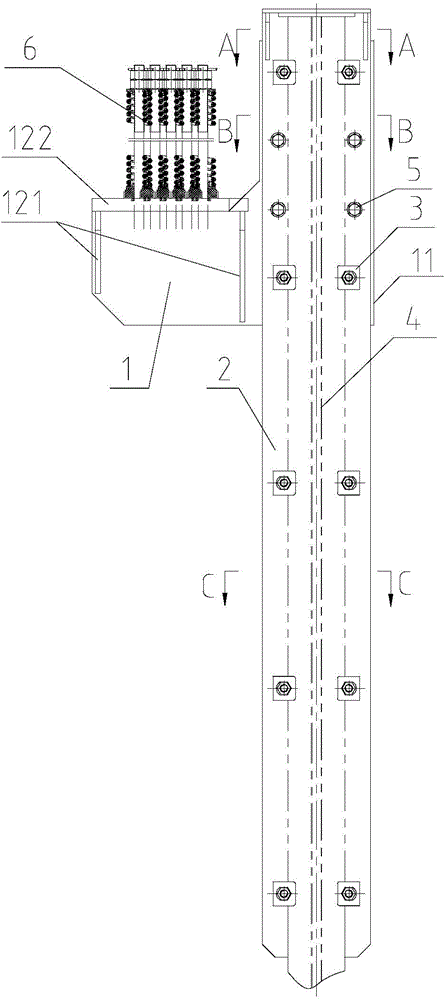

[0018] see Figure 1 to Figure 7 , an elevator car rope head installation structure, including a rope head plate 1, a guide rail vertical plate 2, a pressure guide plate assembly 3, a car guide rail 4 and a bolt assembly 5. The car guide rail 4 is pressed and fixed on the guide rail vertical plate 2 by pressing the guide plate assembly 4 .

[0019] The rope end plate 1 is used to connect the car rope end, and it has a connecting portion 11 connected with the guide rail vertical plate 2 and a support portion 12 connected to the car rope end. Such as figure 1 As shown, the rope head plate 1 of this embodiment is an L-shaped flat plate with a vertical part and a horizontal part, and the vertical part of the L-shaped flat plate is attached to the back of the guide rail vertical plate 2 as a connecting part 11, so The horizontal part of the L-shaped flat plate protrudes outward from one side of the guide rail vertical plate 2 as a support portion 12 . The rope head plate 1 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com