Split lens and camera module

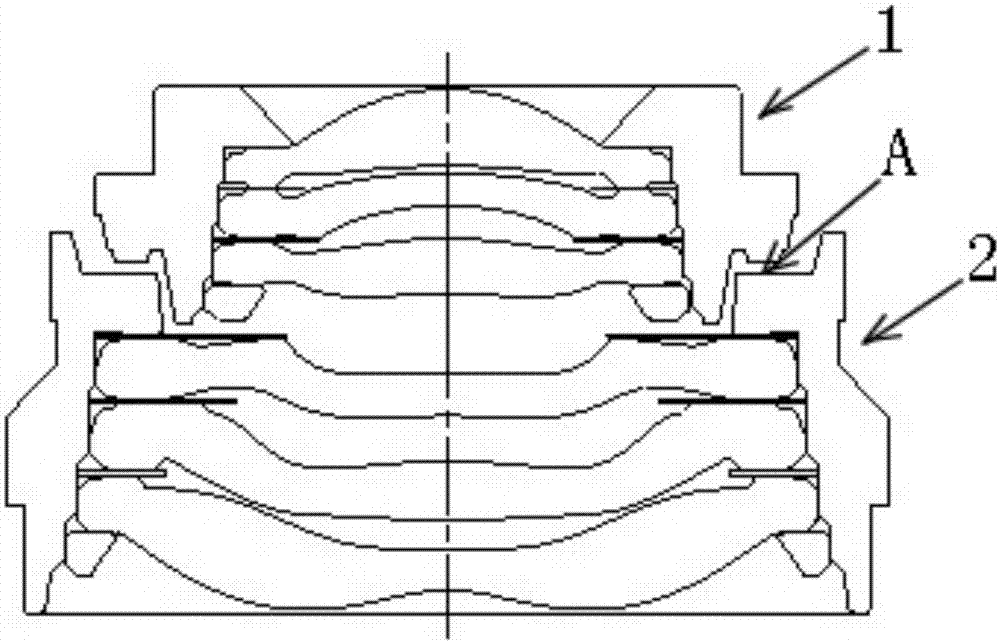

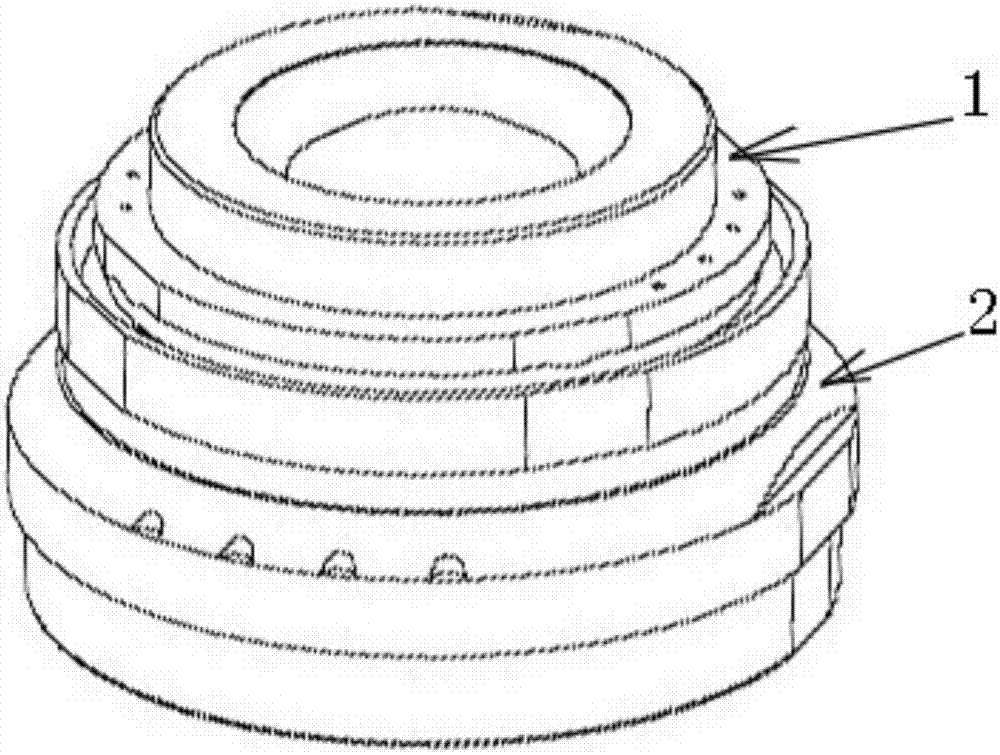

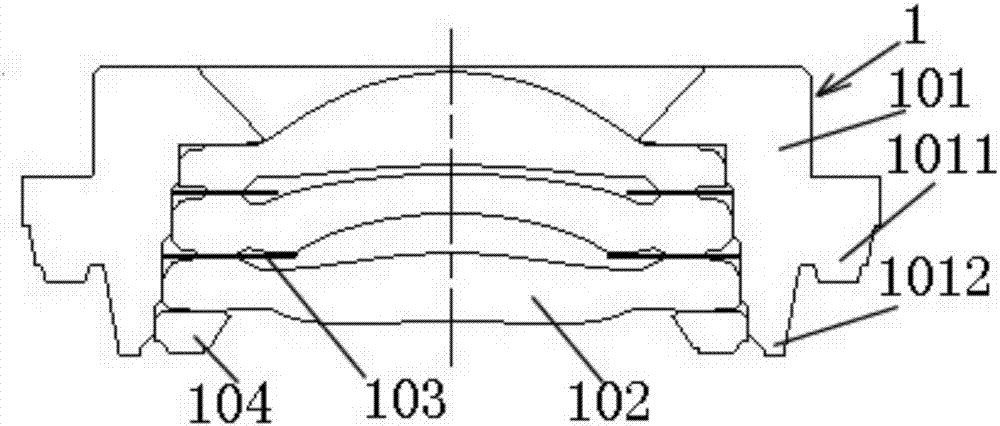

A split-type lens technology, which is applied in the field of split-type lenses and camera modules, can solve problems such as low precision, unguaranteed imaging quality, and large assembly errors of camera modules, achieving good precision, improving matching accuracy and imaging quality, The effect of high placement rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0059] According to one embodiment of the present invention, when assembling the camera module with the above-mentioned split lens according to the present invention, because the diaphragm is arranged in one of the lens barrels of the split lens, it is no longer necessary to spend time assembling the diaphragm , In addition, because the assembly of the split lens is convenient and fast, the speed of assembling the camera module according to the present invention is faster, compared with the assembly method of the camera module containing the split lens in the prior art, it can save a lot of The assembly time is very high, and the assembly efficiency is very high, while ensuring the matching accuracy and imaging quality of the camera module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com