Vegetable dehydrator with elastic dialing mechanism

A technology of elastic paddle and vegetable dehydration, which is applied in the fields of application, food processing, food science, etc., can solve the problems that the swing angle of the conveying chain plate is not large enough, and the conveying chain plate cannot be replaced alternately, so as to improve the operation reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

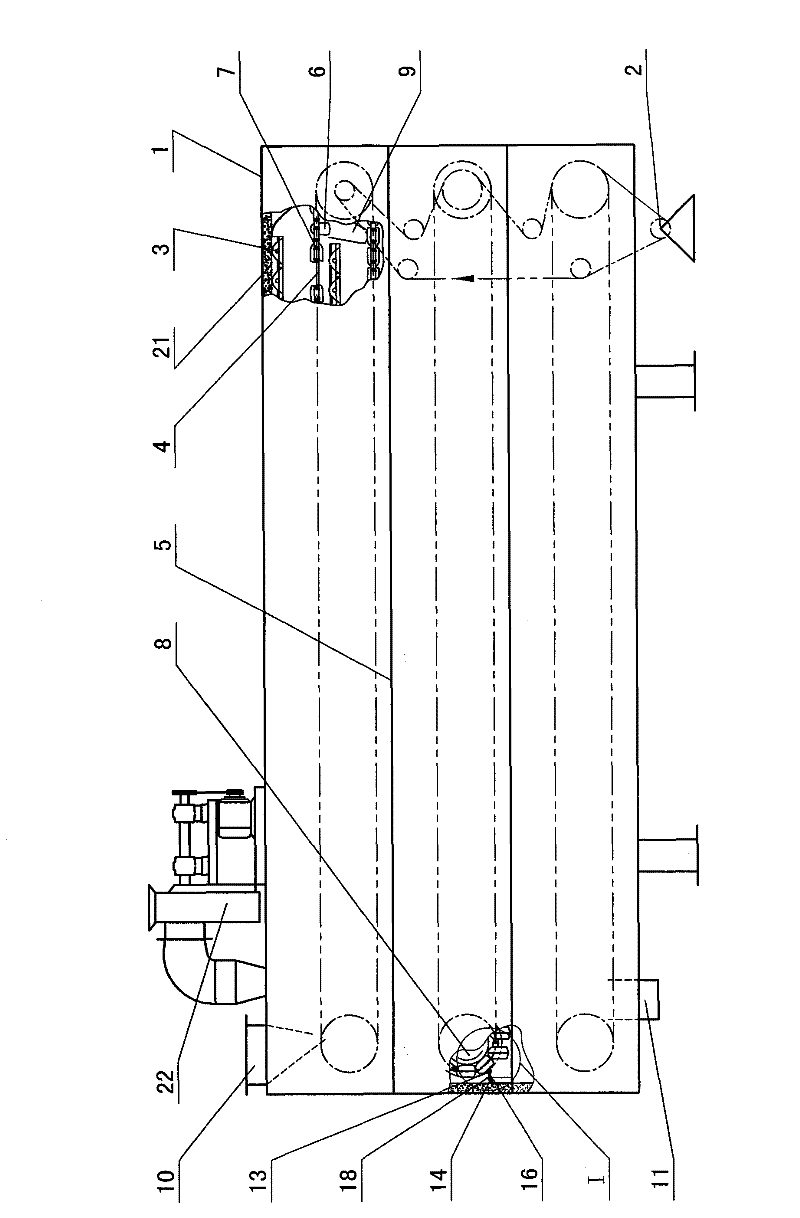

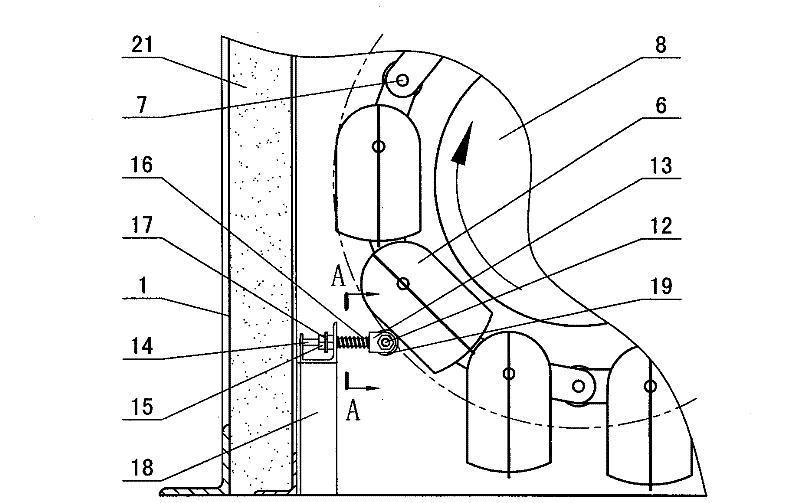

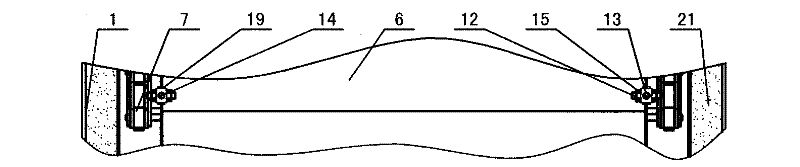

[0032] 1. Drying box 2, transmission device 3, radiation device 4, guide rail 5, partition plate 6, conveying chain plate 7, conveying chain 8, conveying sprocket 9, material guide trough 10, material inlet 11, and material outlet 12 , pin 13, U-shaped frame 14, telescopic rod 15, nut 16, spring 17, limit plate 18, bracket 19, roller 20, rolling bearing 21, insulation layer 22, fan

[0033] exist Figure 1~3 , 5, and 9 in the embodiment shown: the top of the drying box 1 is provided with a feed inlet 10, and the bottom is provided with a discharge opening 11, and the drying box 1 is horizontally spaced into multiple layers by a partition 5, and each layer A group of conveying devices driven by the transmission device 2 are provided. The conveying chain plate 6 of the conveying device is supported on the guide rail 4 to form a trough-shaped material channel, and a material guide trough 9 is arranged at the end of each channel. When the conveying chain plate 6 together with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com