Automatic machine for head-hanging foldable mask

A technology of automatic head and mask, which is applied in the field of mask machine, can solve the problem of excessive packaging materials, and achieve the effects of improved production efficiency, accurate position, and saving packaging materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

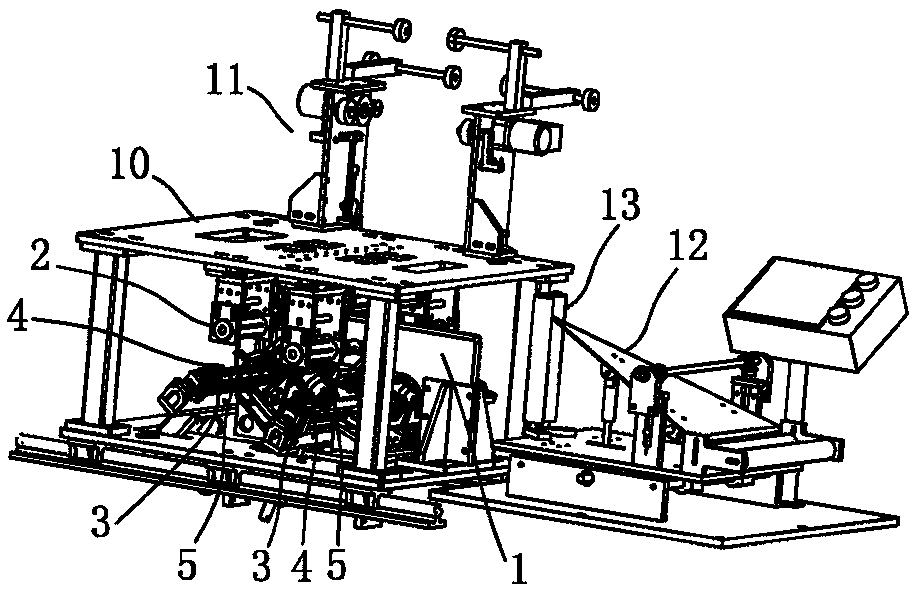

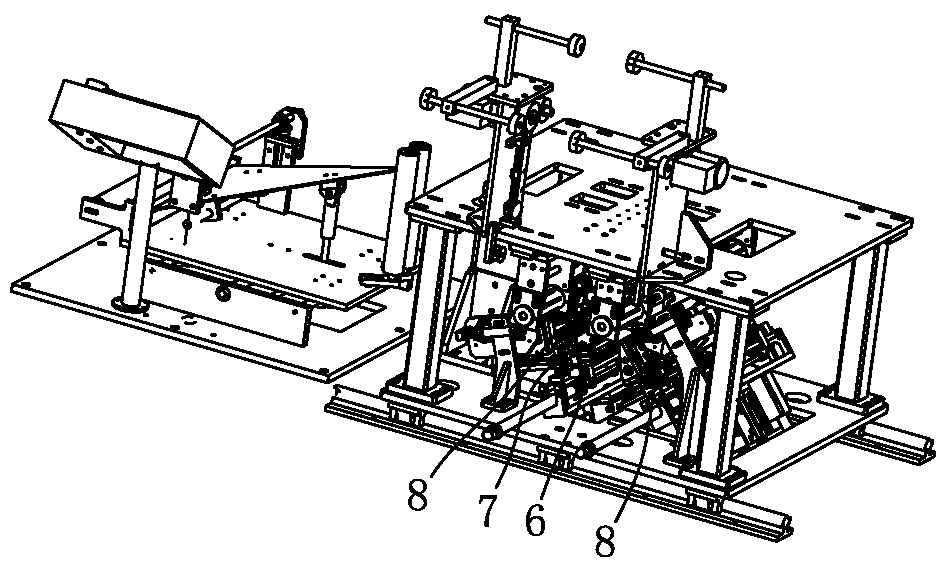

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

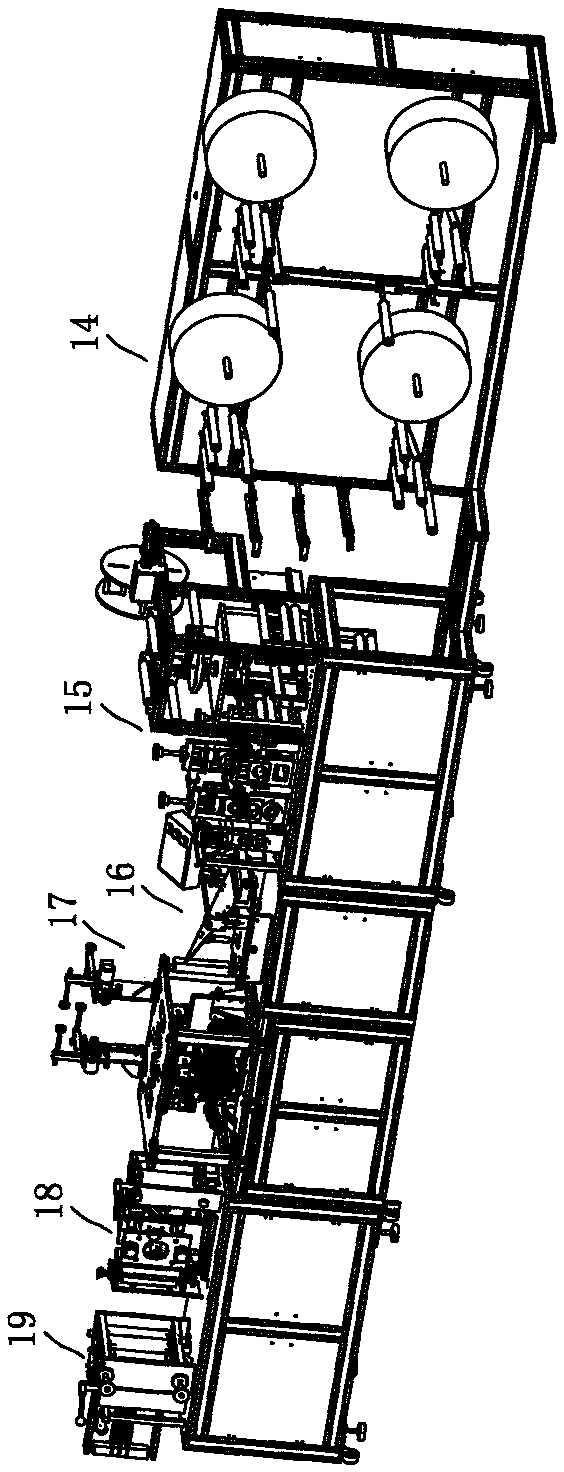

[0024] See figure 1 —— Figure 7 , the automatic head-hanging folding mask machine of the present invention includes: a central inserting plate 1, an ultrasonic welding head 2, a sliding clip track 3, a sliding clip 4, a rotating clip 5, an ear belt feeding seat 6, a guide wheel 7, scissors 8, and a rotating clip drive Seat 9, upper fixing plate 10, ear strap frame 11, double-folding triangular plate 12, clamping roller 13, feeding frame 14, sticking nose bridge line and shape cutting device 15, mask folding device 16, welding ear strap device 17, butt welding forming Device 18, integral molding device 19, front mask 20, back mask 21, front ear band 22, back ear band 23, otch 24.

[0025] The present invention includes a center board 1, an ultrasonic welding head 2, a sliding clip track 3, a sliding clip 4, a rotating clip 5, an ear strap feeding seat 6, a guide whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com