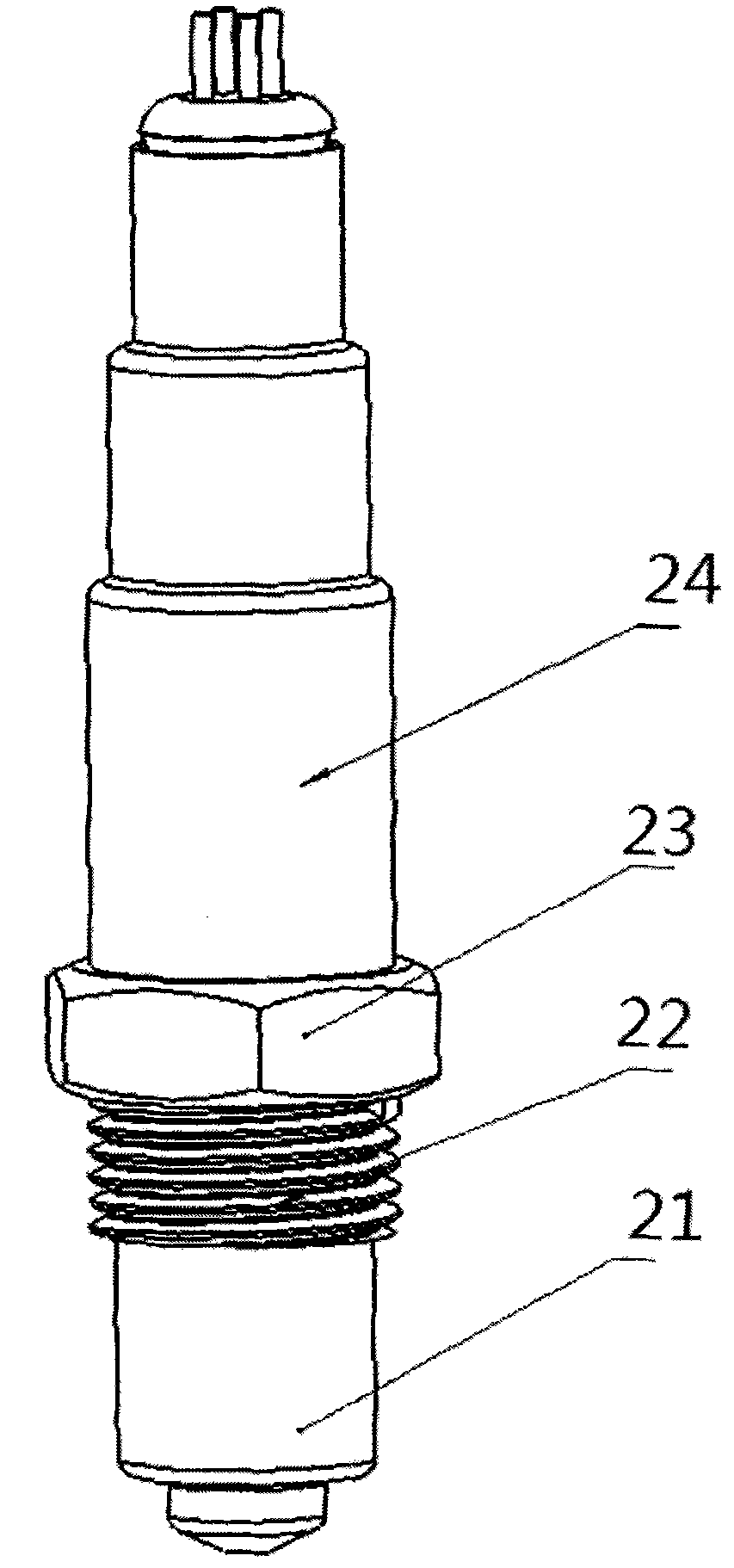

Automatic production line device for packaging oxygen sensor

An automated production line and oxygen sensor technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of relying on labor and low production efficiency, and achieve the effect of stabilizing product quality, improving product quality, and improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

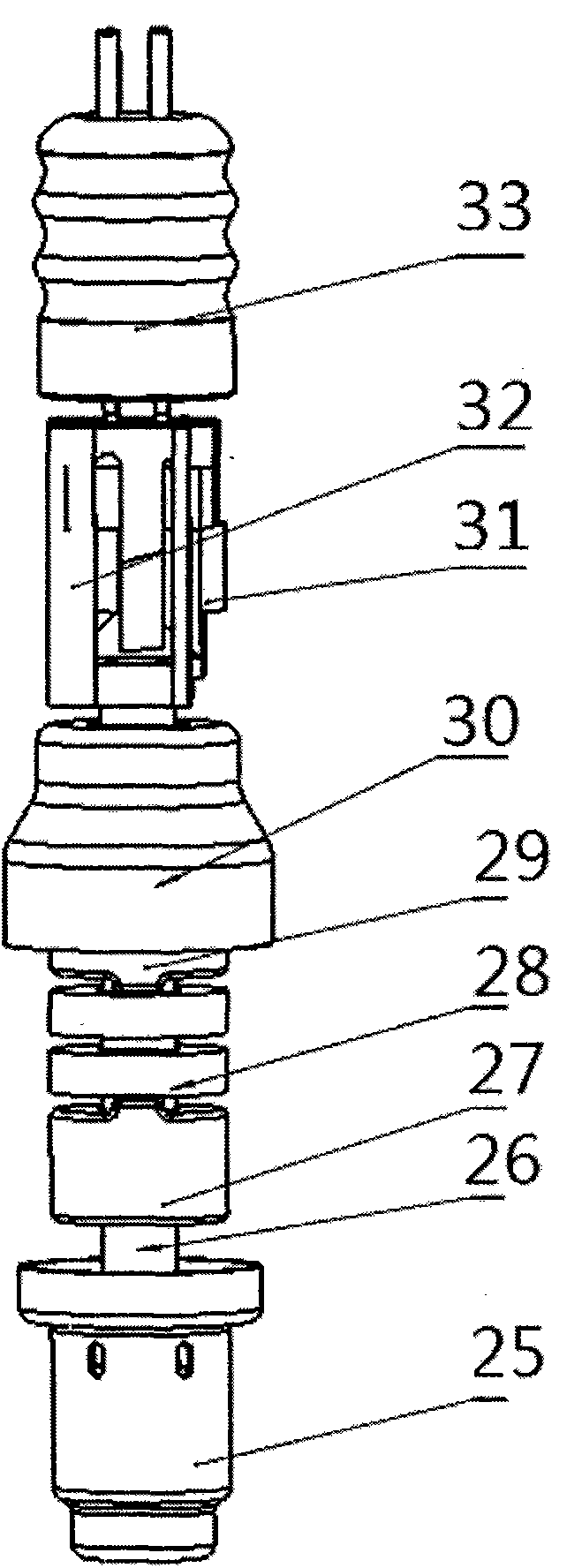

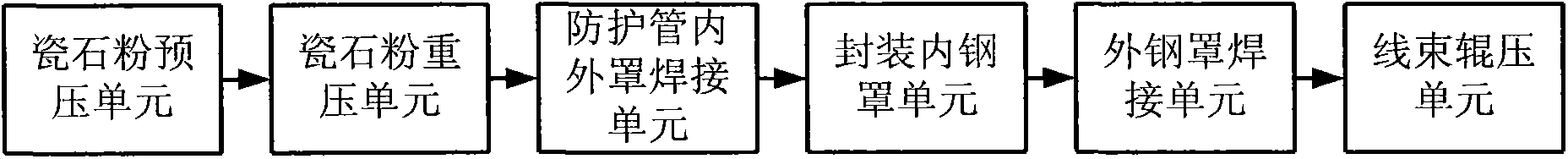

[0079] Such as Figure 3-16 As shown, the present invention provides an automatic production line device for oxygen sensor packaging, which includes a porcelain stone powder pre-pressing unit, a porcelain stone powder repressing unit, a protective tube inner and outer cover welding unit, a packaging inner steel cover unit, and an outer steel cover welding unit sequentially connected by a conveyor belt. unit and harness rolling unit.

[0080] The oxygen sensor packaging automatic production line device can be designed as fully automatic or semi-automatic as required. If it is fully automatic, it needs to be equipped with a manipulator, that is, after each unit is processed, the manipulator will move the workpiece to the conveyor belt, and the conveyor belt will automatically transport it to the next unit, and then another manipulator wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com