Secondary battery

A secondary battery, conductive layer technology, applied in secondary batteries, secondary battery manufacturing, battery pack components, etc., can solve problems affecting battery safety and cycle life, inability to precisely control welding positions, unfavorable processes, and quality control and other problems, to achieve the effect of easy flow operation, reliable and firm connection points of the tabs, and guaranteed performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

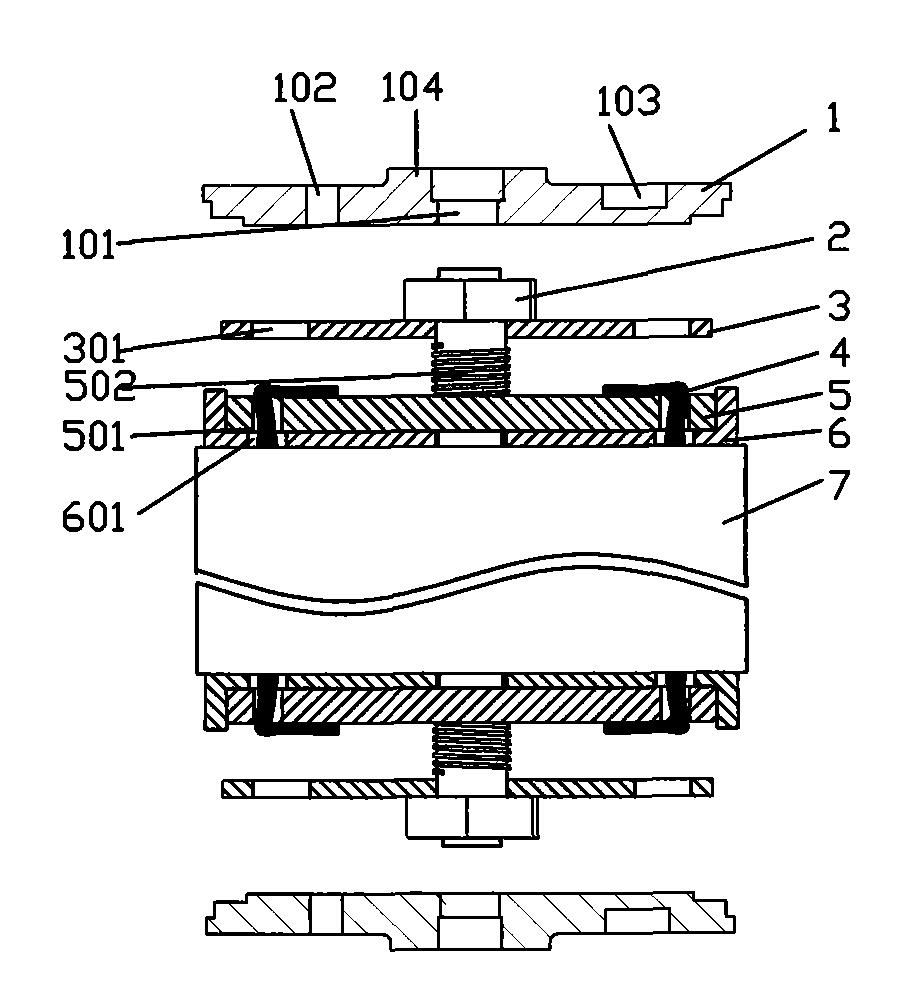

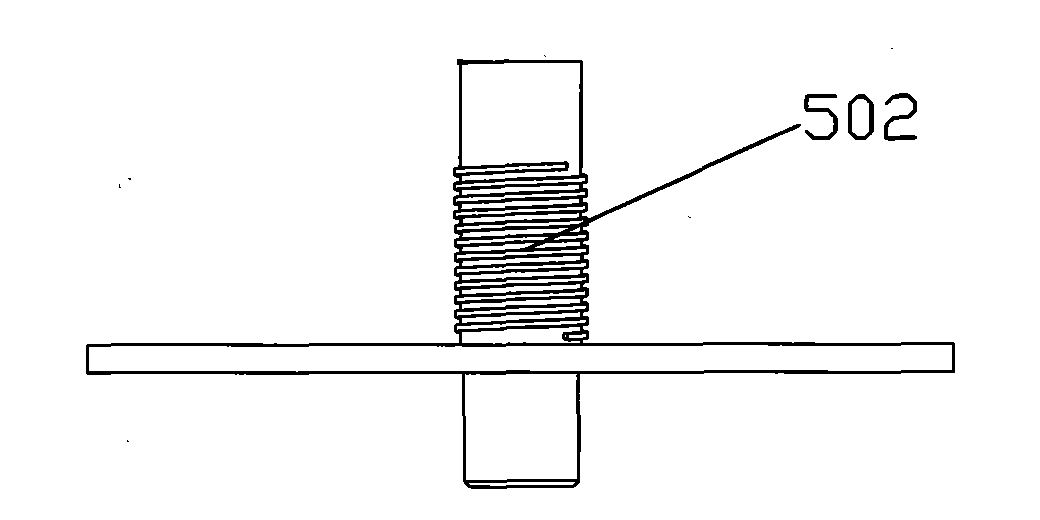

[0046] A secondary battery such as figure 1 As shown, the cover plate 1, the connecting piece, the tab lead-out device, the second gasket 3, and the winding core 7 are included. The tab lead-out device includes an insulating pad 6 and a first pad 5, wherein the insulating pad 6 constitutes an insulating layer, and the first pad 5 constitutes a conductive layer. The connecting piece includes a nut 2 and a screw 502 fixed on the first washer. The battery plates are wound into a cylindrical winding core 7, with a plurality of tabs 4 extending out of the core 7, one of which is a positive tab, and the other end is a negative tab. The tabs at both ends are connected with The connection structure of the cover plate is the same.

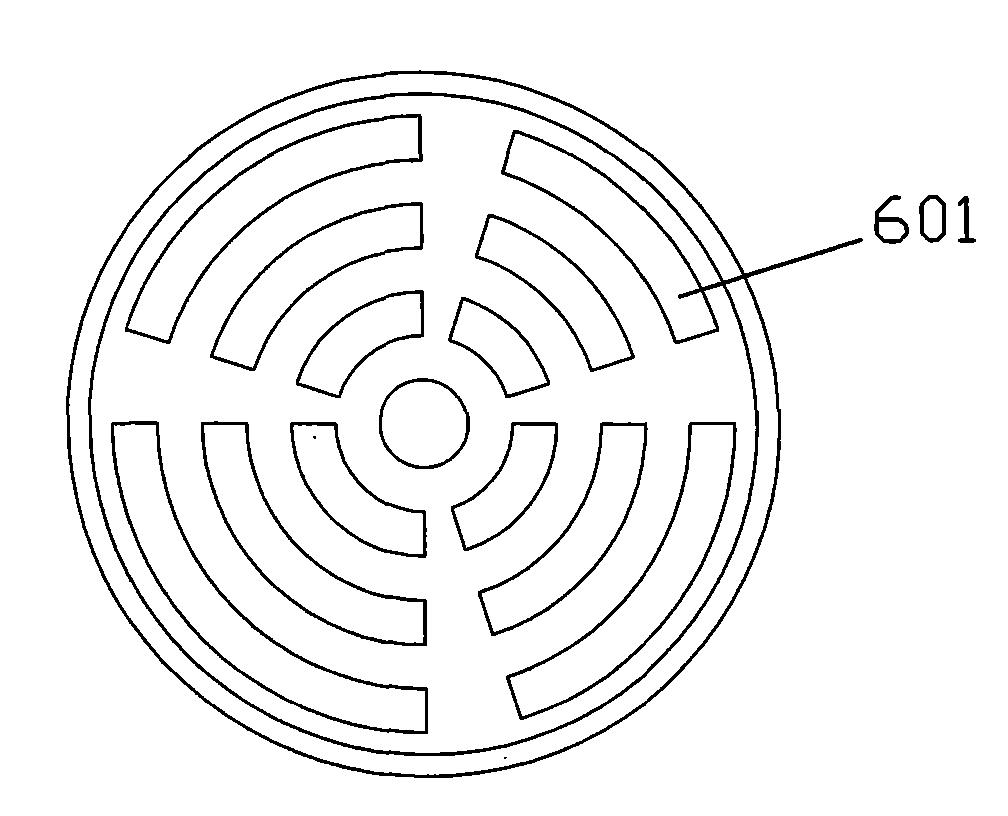

[0047] The insulating gasket 6 is circular and placed on the end face of the winding core 7. The structure of the insulating gasket 6 is as follows: figure 2 As shown, a hole 601 is opened thereon, and the hole 601 is an intermittent fan shape. A first gasket...

Embodiment 2

[0053] A secondary battery includes a cover plate, a connecting piece, a tab lead-out device, a second gasket, and a winding core. The difference from Embodiment 2 is that the tab lead-out device is a composite of an insulating layer and a conductive layer. Structure. Such as Figure 7 As shown, the tab extraction device is divided into upper and lower layers. The upper layer is a conductive layer and the lower layer is an insulating layer. The tabs pass through the pores on the tab extraction device from below the insulating layer and are welded on top of the conductive layer.

Embodiment 3

[0055] A secondary battery includes a cover plate, a connecting piece, a tab lead-out device, a second gasket, and a winding core. The difference from Embodiment 2 is that the tab lead-out device is not provided with a hole, such as Figure 8 As shown, the tabs extend from the edge of the tab lead-out device from below the insulating layer and are welded on top of the conductive layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com