Linear compressor and oil supply method thereof

A linear compressor and oil pipe technology, applied in the field of compressors, can solve the problems of reducing the performance and reliability of the linear compressor, increasing the power consumption of the linear compressor, and large loss of components, so as to increase the performance stability and service life, reduce the The effect of frictional power consumption and life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

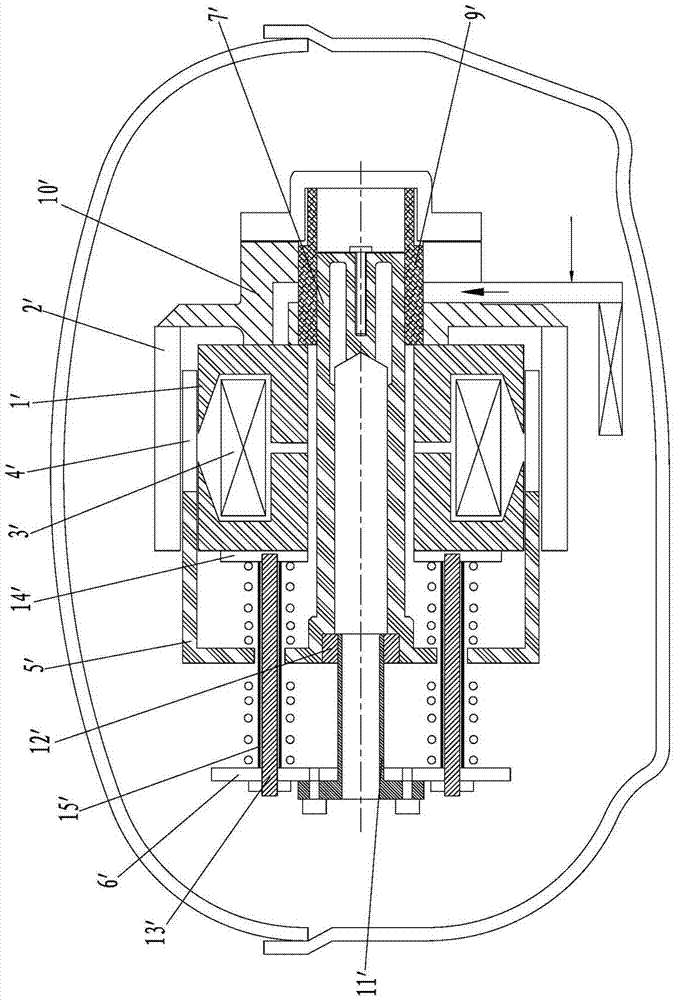

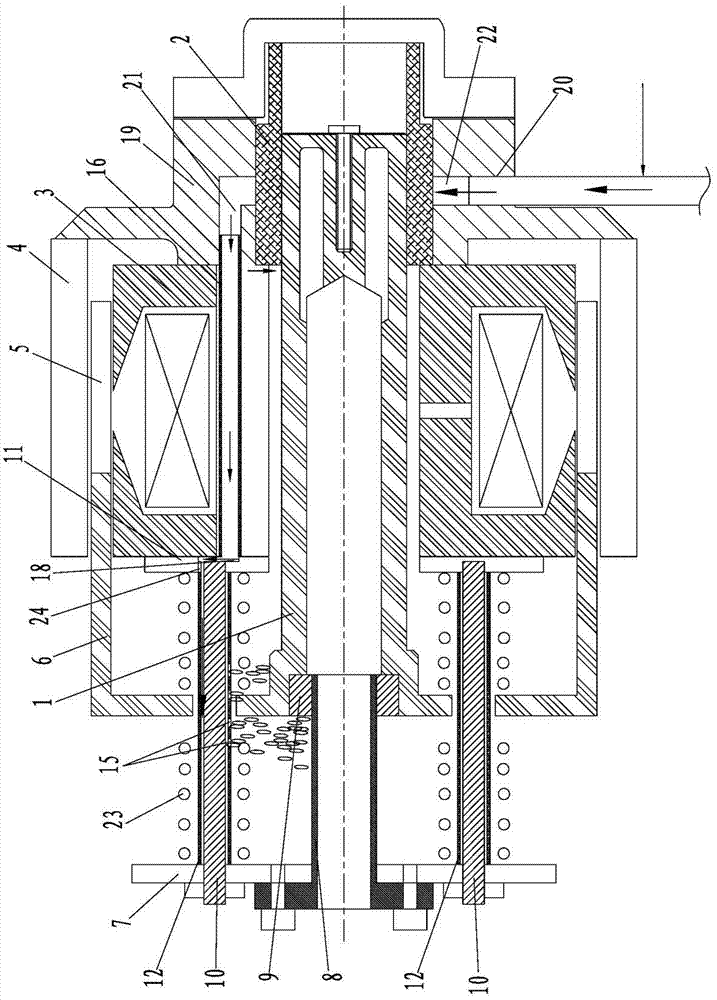

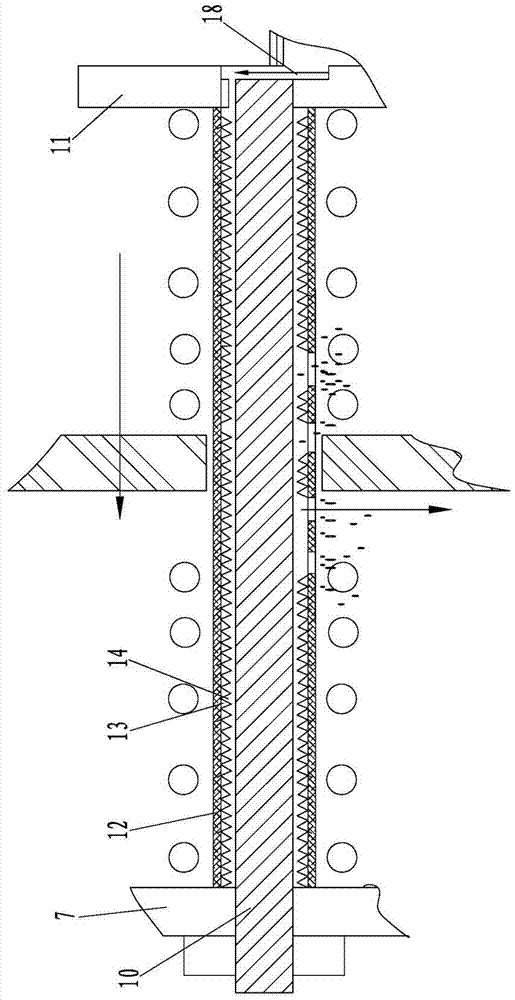

[0032] Such as figure 2 and image 3 Shown is a linear compressor of the present invention, including a linear motor, a piston 1, a cylinder 2, a front flange 19, and the like. The linear motor includes a stator and a mover 5, and the stator includes a fixed inner stator 3 and an outer stator 4. Both the inner stator 3 and the outer stator 4 are formed by stacking a plurality of silicon steel sheets. The mover 5 is connected with the mover skeleton 6 to form a mover component. The mover skeleton 6 is connected with the piston 1 . The center position of the left end of the piston 1 is connected with a positioning shaft 8, and a bearing 9 is arranged between the positioning sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com