Axial spacing stopper pin device

A technology of axial limit and shaft pin, applied in the direction of mechanical equipment, connecting components, etc., can solve the problems of inconvenient use, troublesome disassembly and assembly, etc., and achieve the effects of quick disassembly, convenient operation and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

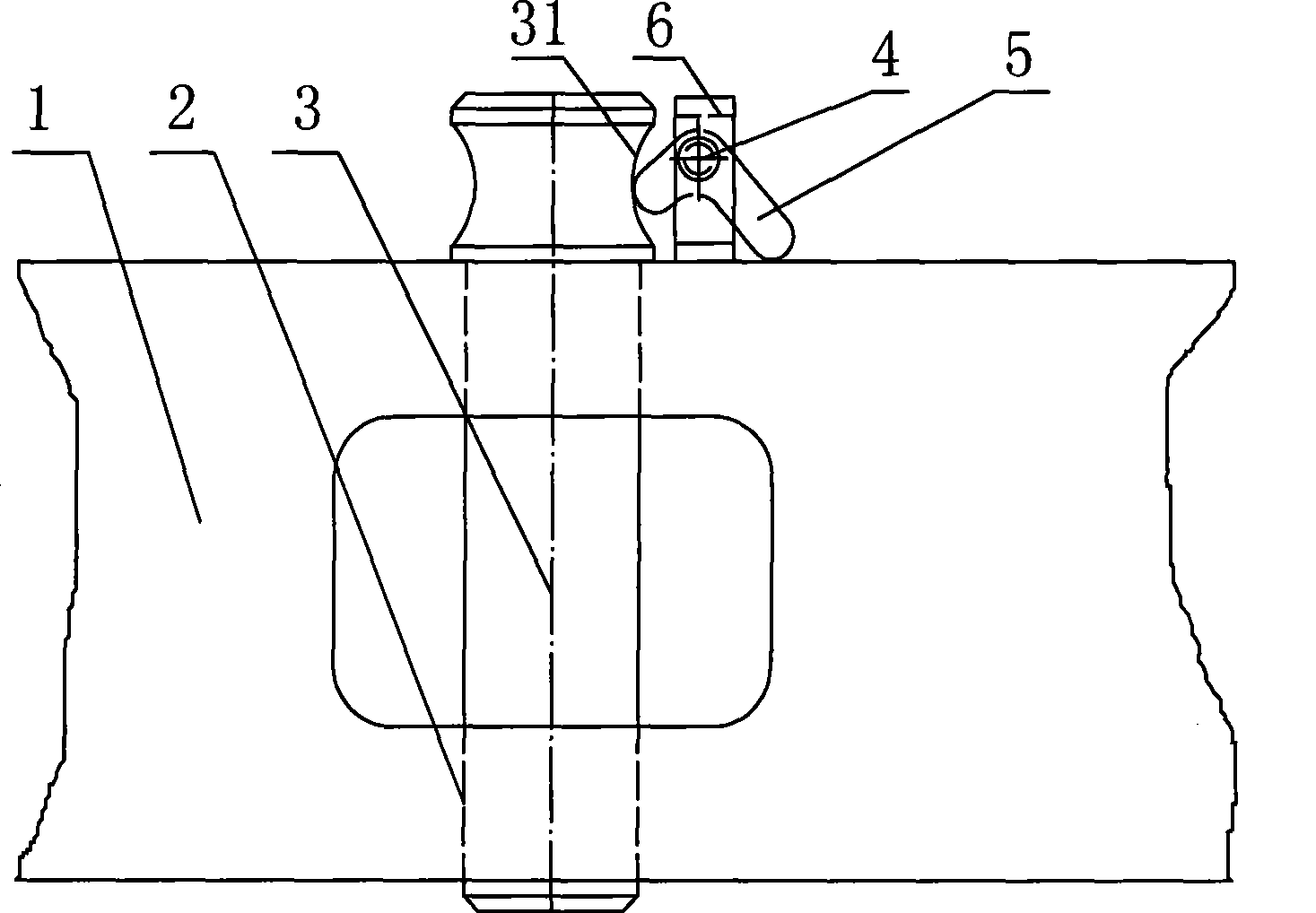

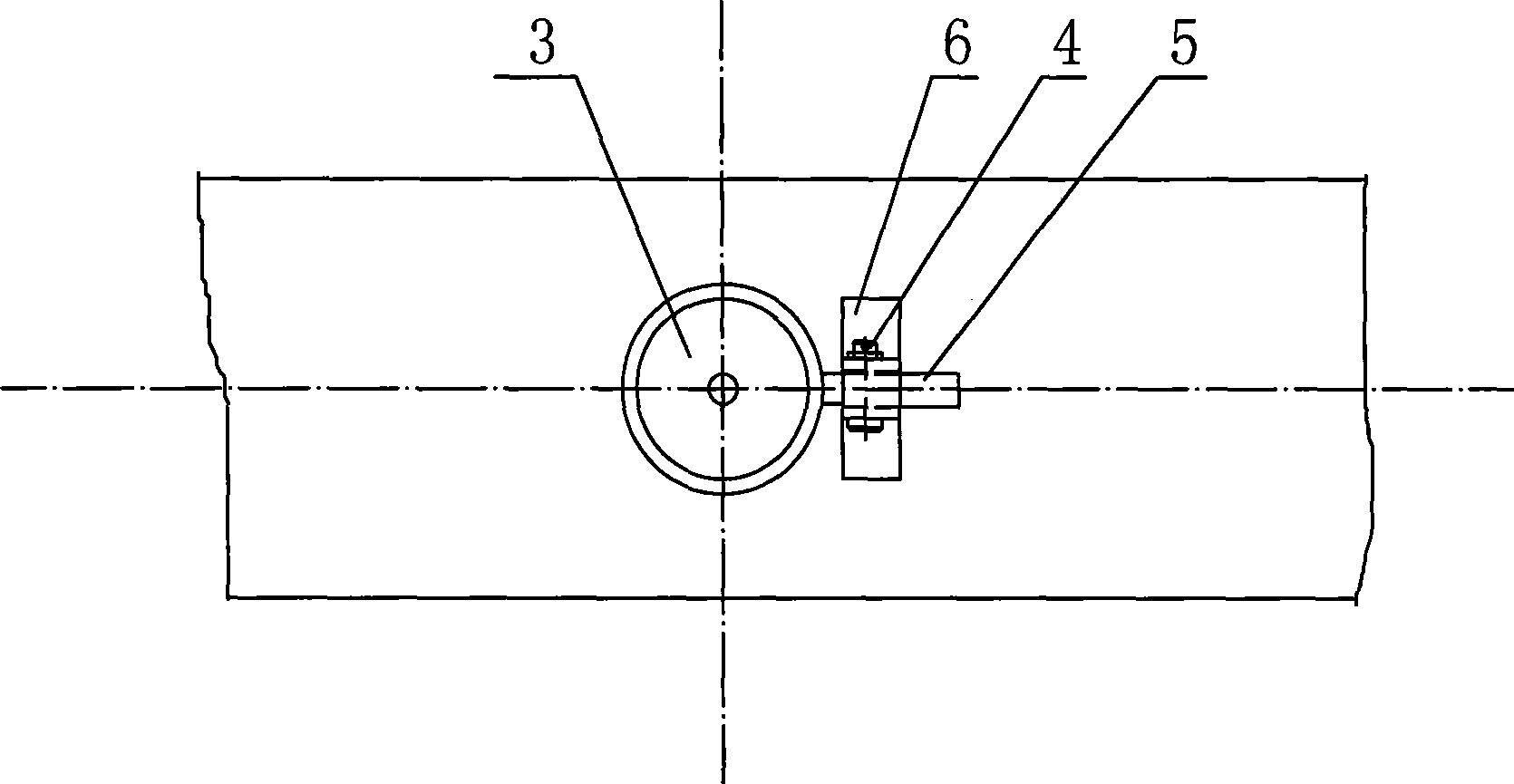

[0017] A kind of pin stop mechanism of axial limit of the present invention such as figure 1 , figure 2 As shown, a vertical pin hole 2 is provided on the shaft pin seat 1, and the shaft pin 3 is inserted in the pin hole 2. There is a clearance fit between the shaft pin 3 and the pin hole 2, which is used to connect the two components together. . The upper end of axle pin 3 is provided with a thicker nose portion 32 (referring to Figure 4 ), to prevent the shaft pin 3 from falling from the pin hole 2, the protruding head 32 is provided with a ring-shaped groove 31, preferably the cross-sectional shape of the groove 31 is arc-shaped.

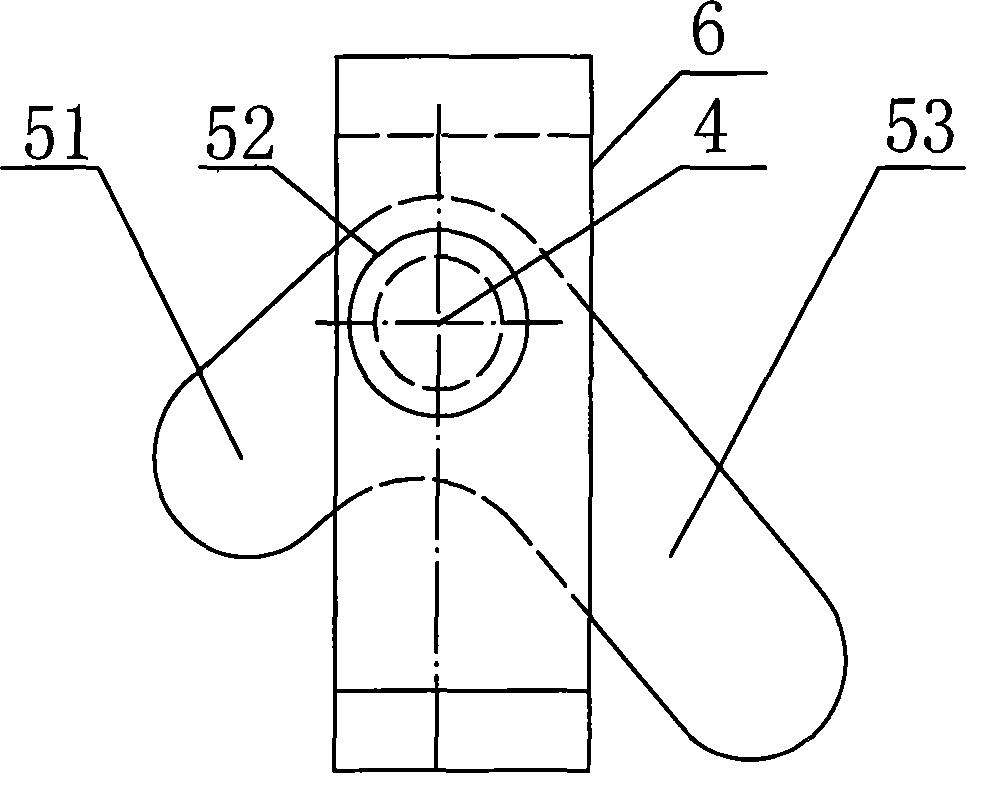

[0018] A support 6 is fixed near the pin hole 2 on the shaft pin seat 1 , a horizontal rotating shaft 4 is installed on the support 6 , and a rocking arm 5 is rotatably installed on the rotating shaft 4 . to combine image 3 The rocker arm 5 is provided with a locking portion 51, a rotating shaft hole 52 and a drooping portion 53, the locki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com