Full-automatic ball attachment machine

A fully automatic, ball-planting technology, applied in tin feeding devices, metal processing equipment, manufacturing tools, etc., can solve the problems of waste of solder paste, long processing time, and large consumption of solder paste, so as to reduce production costs and shorten the Processing time, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

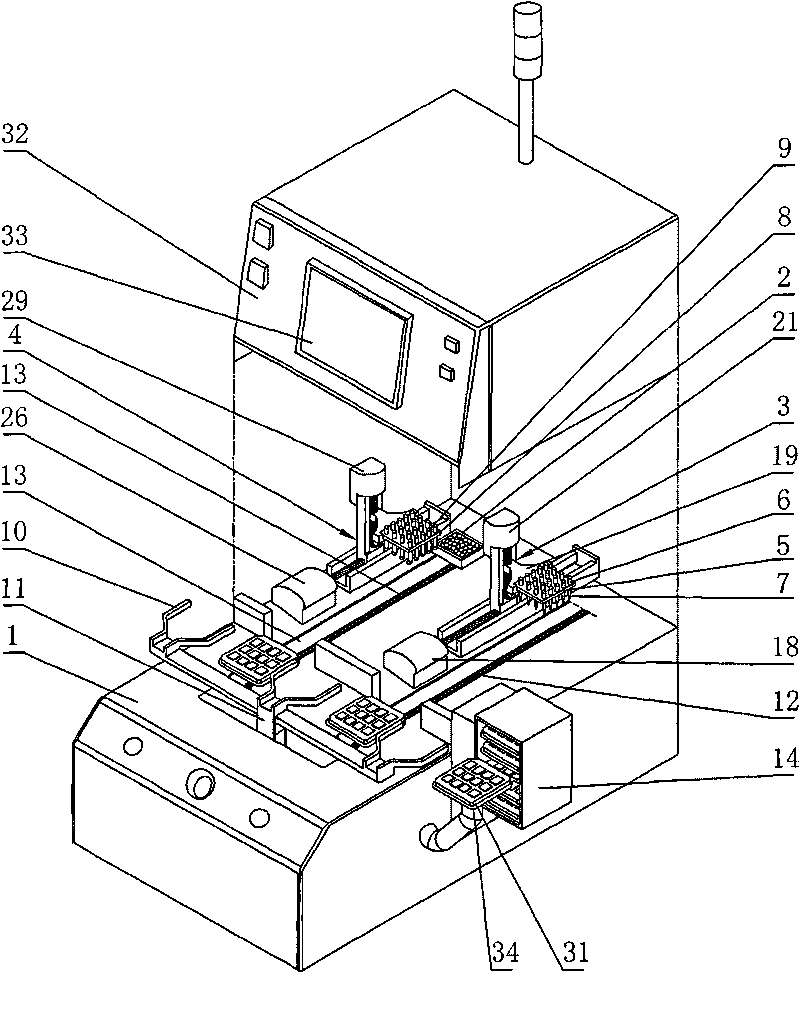

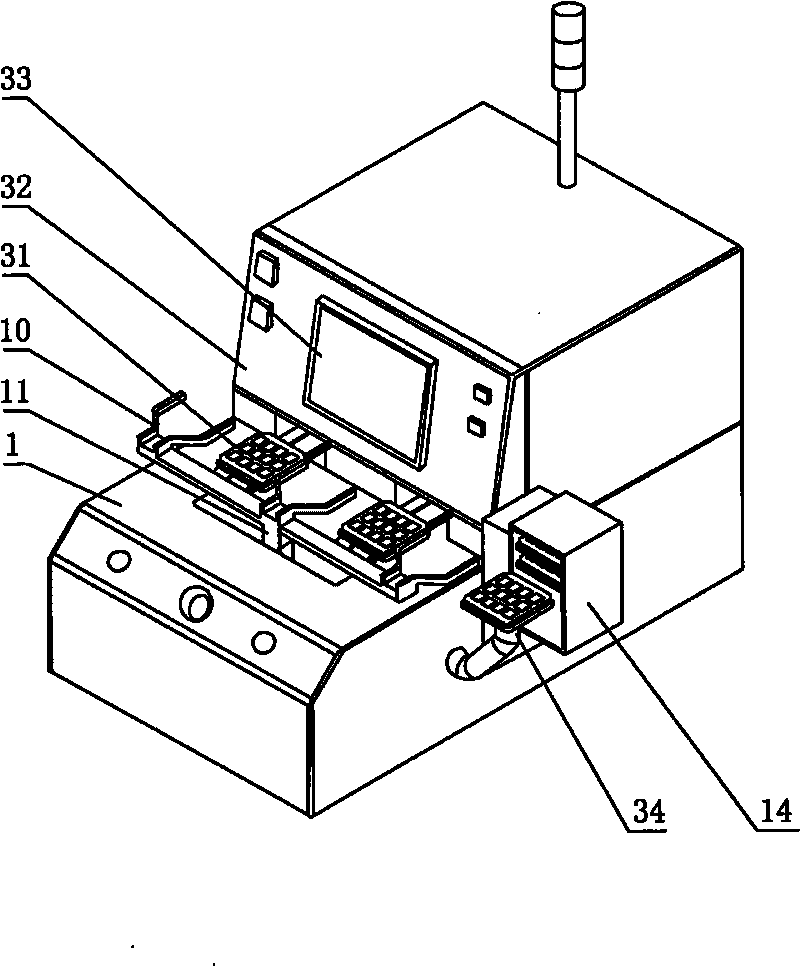

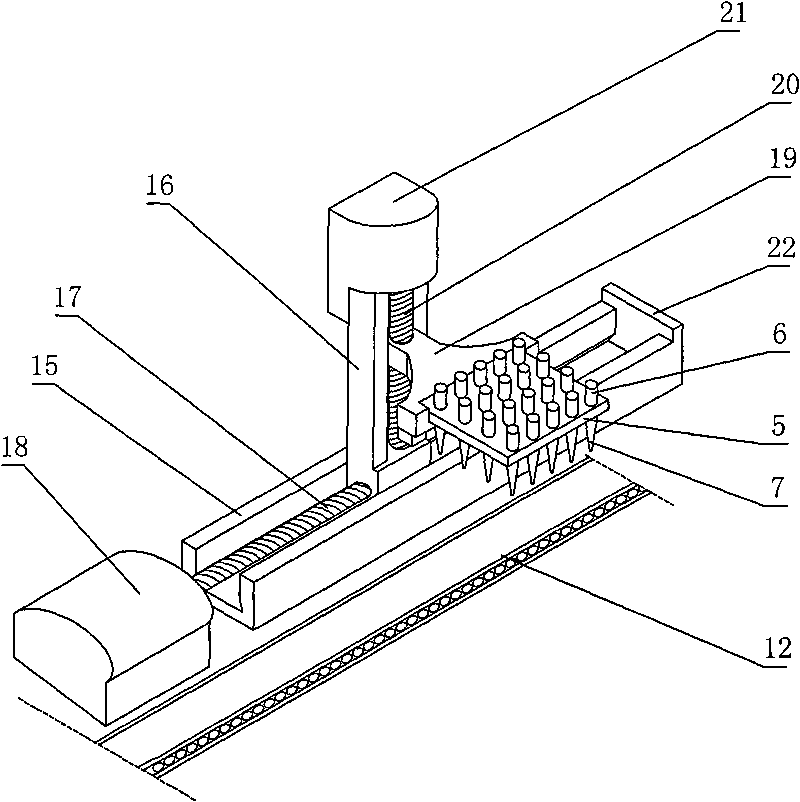

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] figure 1 It is the structural representation that the sealing cover of the present invention moves upwards to the workbench, figure 2 It is a schematic diagram of the appearance and structure of the present invention, as shown in the figure: the automatic ball planting machine includes a workbench 1, a conveyor chain arranged on the workbench 1, a solder ball storage disk 2, a loading and unloading manipulator 10, a substrate storage box 14, and The solder paste dripping device 3 is used to drip the solder paste into the electrical component installation holes on the substrate 31 to be processed, and the solder ball placement device 4 is used to place the solder balls in the electrical component installation holes on the substrate 31 to be processed. Conveyor chain comprises the dripping glue conveying chain 12 and the ball p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com