Hold-down device and welding equipment with hold-down device

A technology of pressing device and pressing plate, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of welding deformation, increasing welding process time and procedure, inaccurate positioning of pressing device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

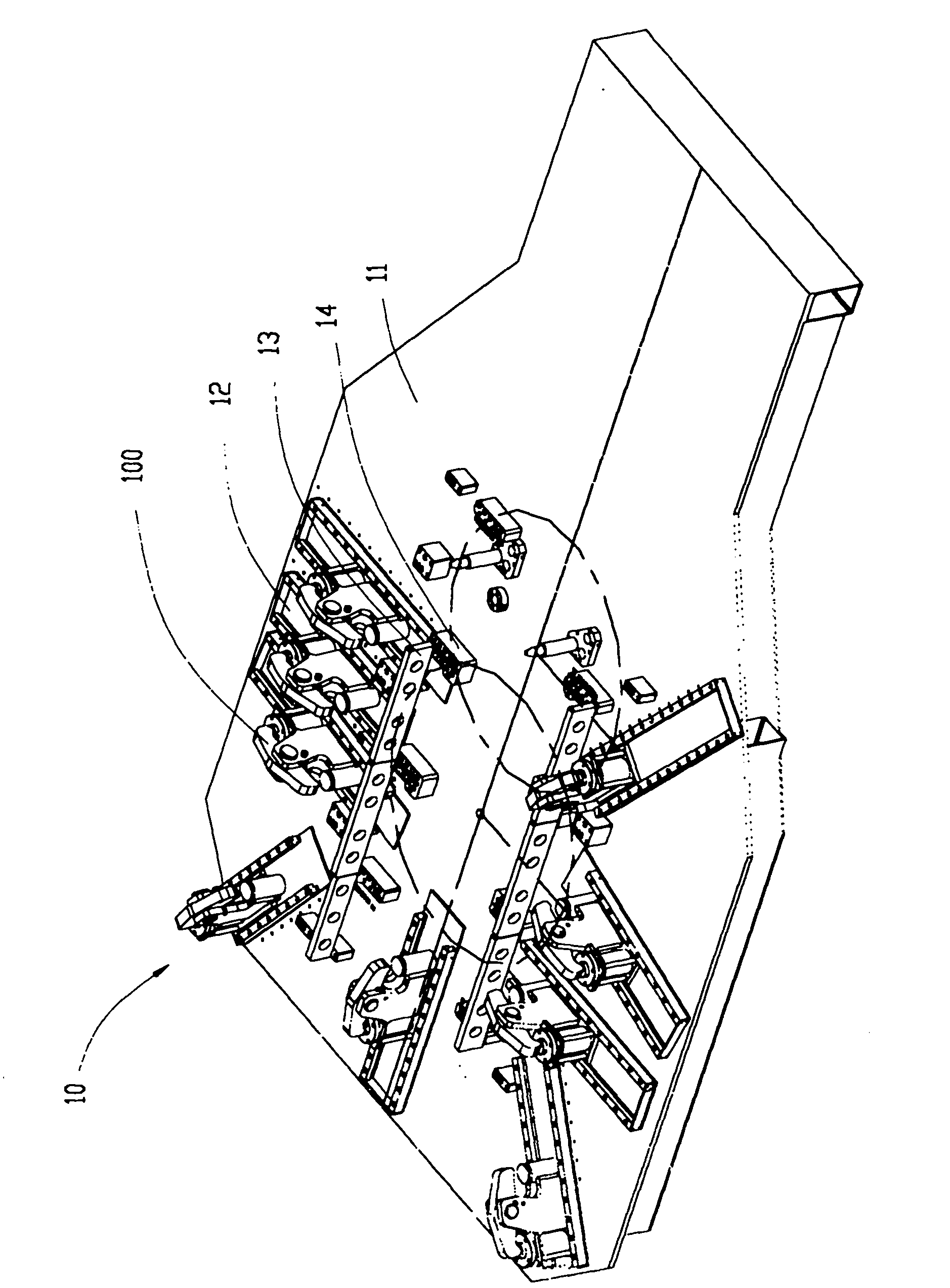

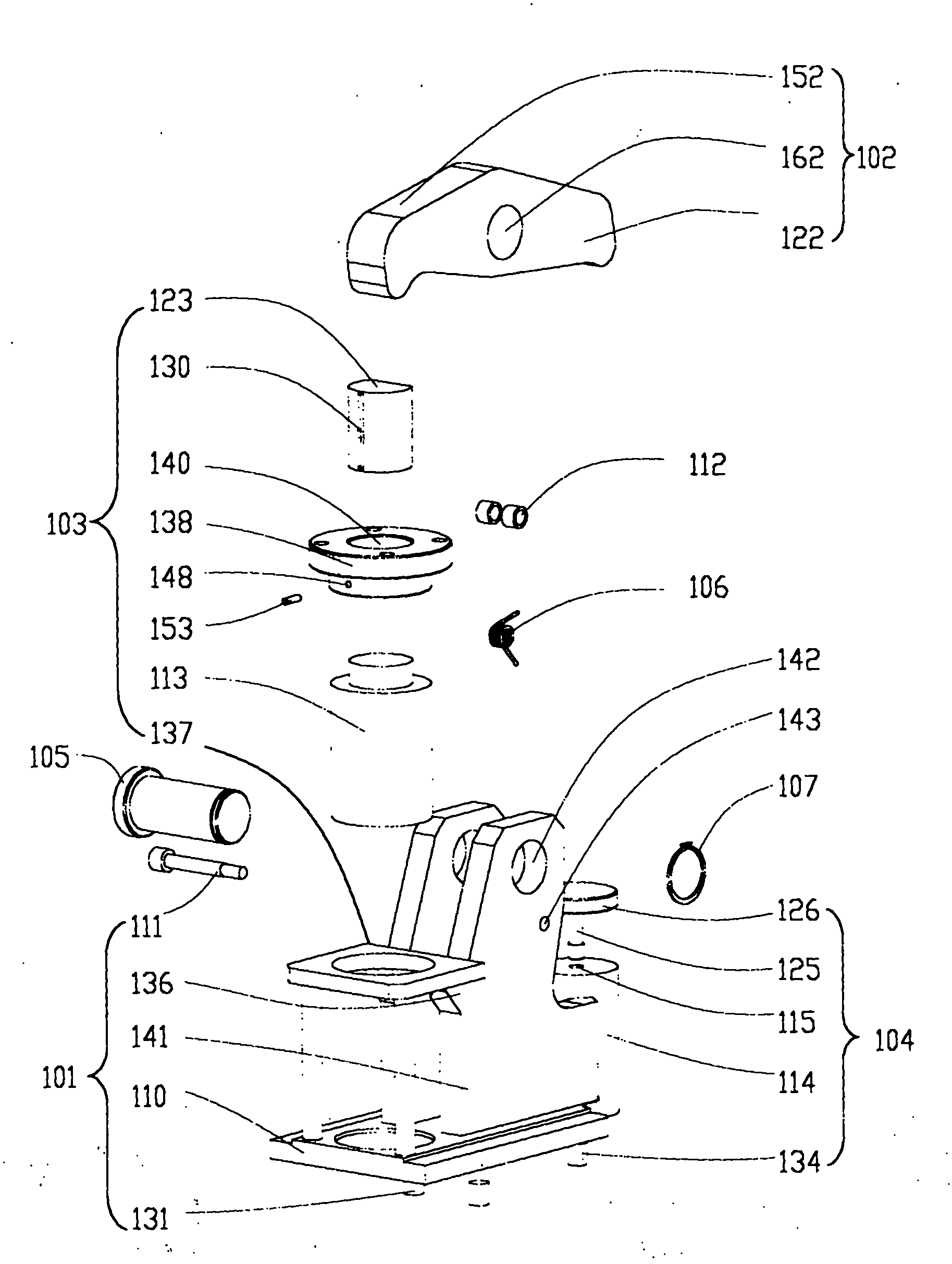

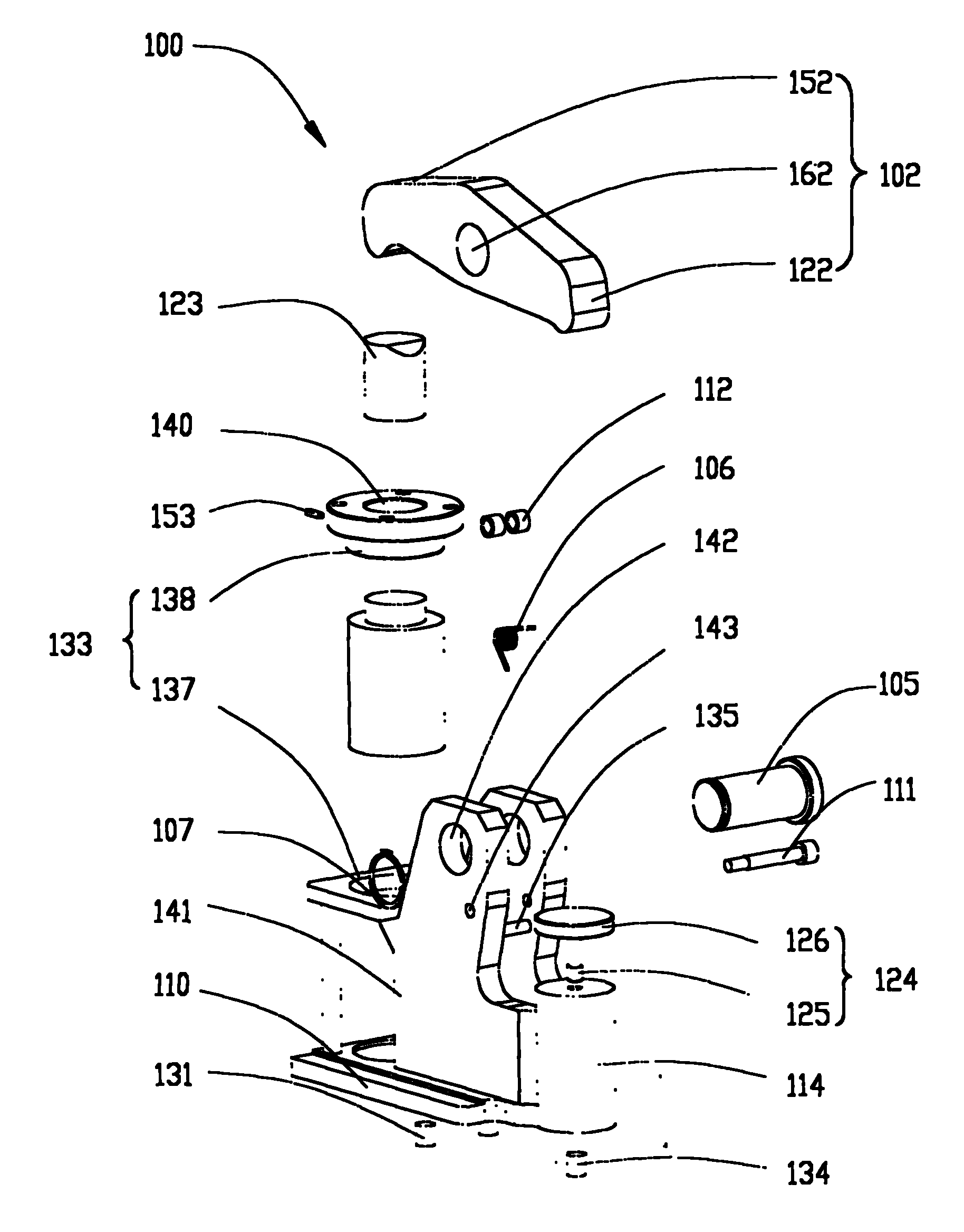

[0014] see figure 1 and figure 2 , is a perspective view of the welding device 10 and an exploded view of the pressing device 100 in a preferred embodiment. The welding device 10 includes a bottom plate 11 , a rail 12 disposed on the bottom plate 11 , a support 13 and a positioning block 14 for positioning the support 13 . The shape and size of the bottom plate 11 are adapted to the size of the welding workpiece 200 .

[0015] The pressing device 100 is fixed on the track 12 on the bottom plate 11 . The pressing device 100 includes a bracket 101 , a pressing plate 102 rotatably fixed on the bracket 101 , a power mechanism 103 for pushing the pressing plate 102 to rotate, and a supporting mechanism 104 for supporting the welding workpiece 200 . In addition, the pressing device 100 further includes a rotating member 105 that rotatably connects the bracket 101 and the pressing plate 102 , and an elastic member 106 that restores the pressing plate 102 .

[0016] Please refer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com