Karst rich water tunnel water-proof and drainage construction method

A technology for water-rich tunnels and construction methods, applied in drainage, tunnels, tunnel linings, etc., can solve problems such as difficult construction, potential safety hazards, and poor application, and achieve the effects of improving work efficiency, reducing project cost, and improving efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

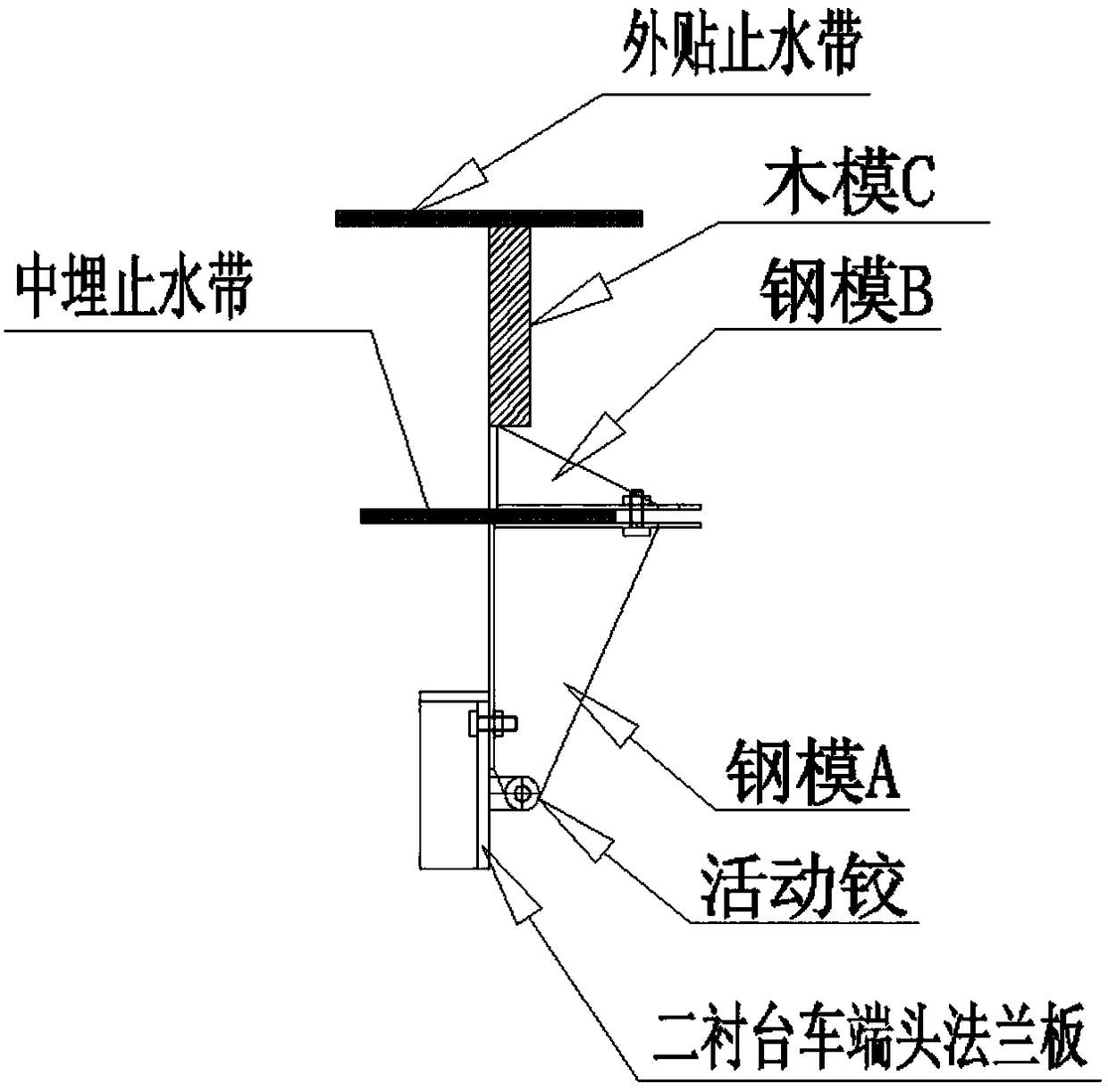

[0032] Waterproof and Drainage Construction of Karst Water-rich Tunnel

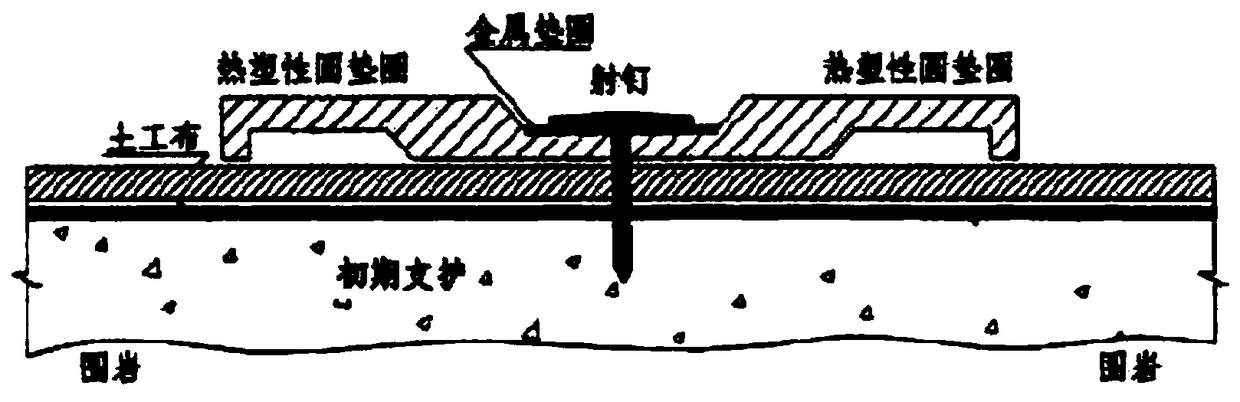

[0033] 1.1 Surface treatment of surrounding rock or primary support

[0034] Before laying the waterproof layer, the base surface (primary support surface) should be inspected for water leakage, exposed protrusions and surface unevenness.

[0035] 1.1.1 Use grouting to block water or drain blind pipes, drainage boards, etc. to introduce water into the side ditch at the leaking water, so as to keep the base surface without obvious water leakage.

[0036] 1.1.2 For the protruding part of the anchor rod head, steel pipe head, steel bar head, etc. exposed to the base surface, cut it off first, then use a hammer to rivet it flat, and apply mortar.

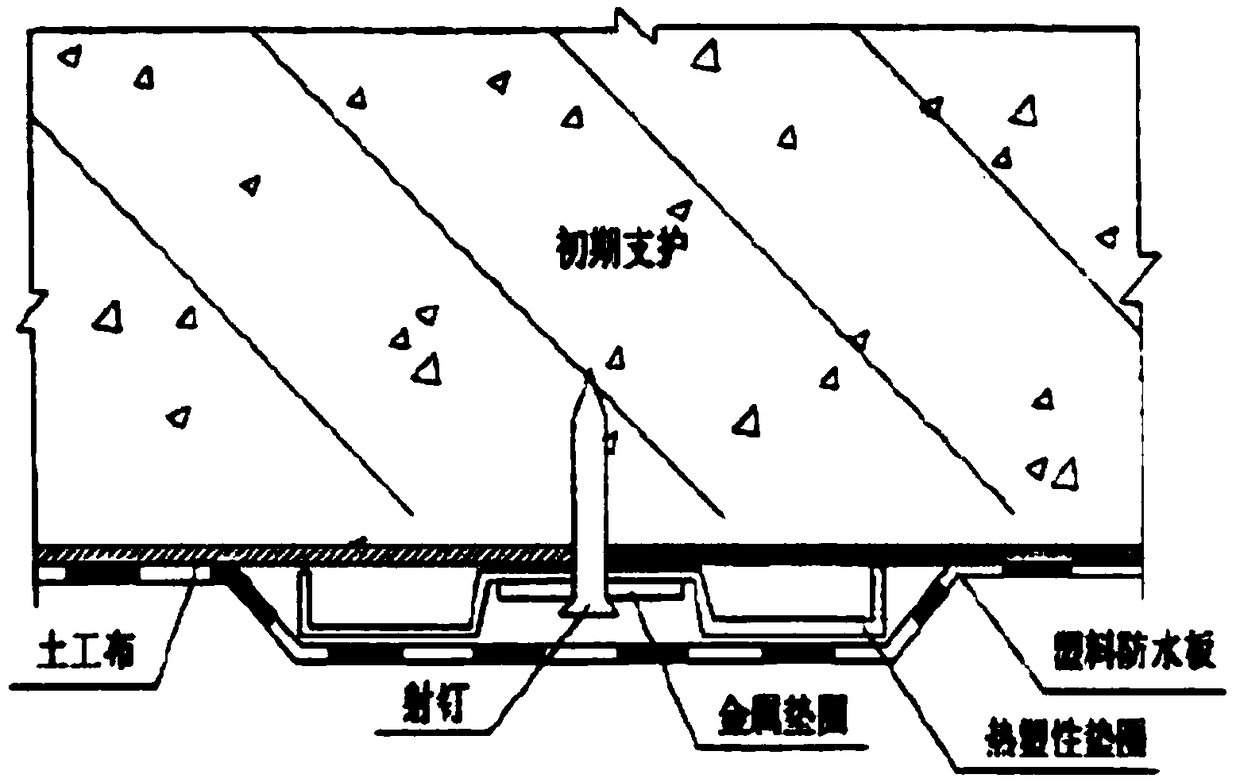

[0037] 1.2 Drainage blind pipe setting

[0038] The back of the secondary lining waterproof board of the whole tunnel is provided with a circular φ50 single-wall perforated corrugated pipe (wrapped in non-woven fabric) drainage blind pipe, and a φ80 single-wall p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com