Box beam welding equipment and welding method

A technology for welding equipment and box beams, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of uneven technical level of welding personnel, great physical and mental injury of welding personnel, and inability to guarantee welding quality, and achieves a high level of improvement. Weld quality, reduced damage, tight weld results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

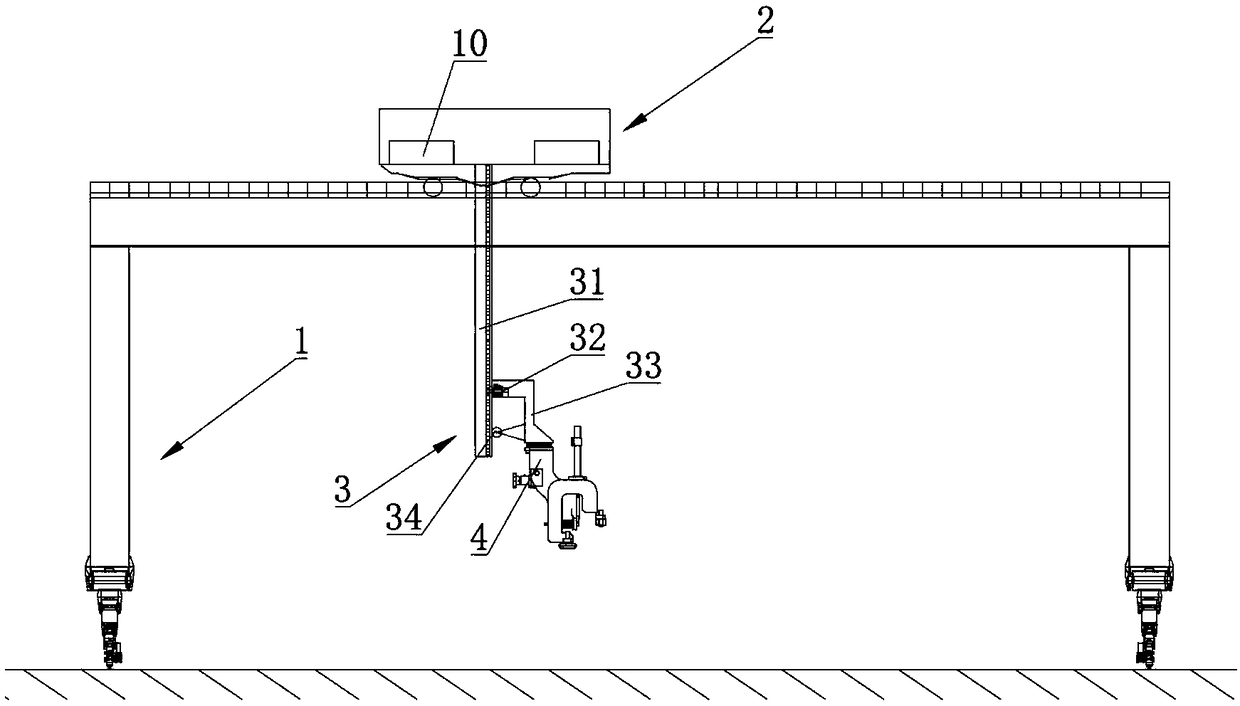

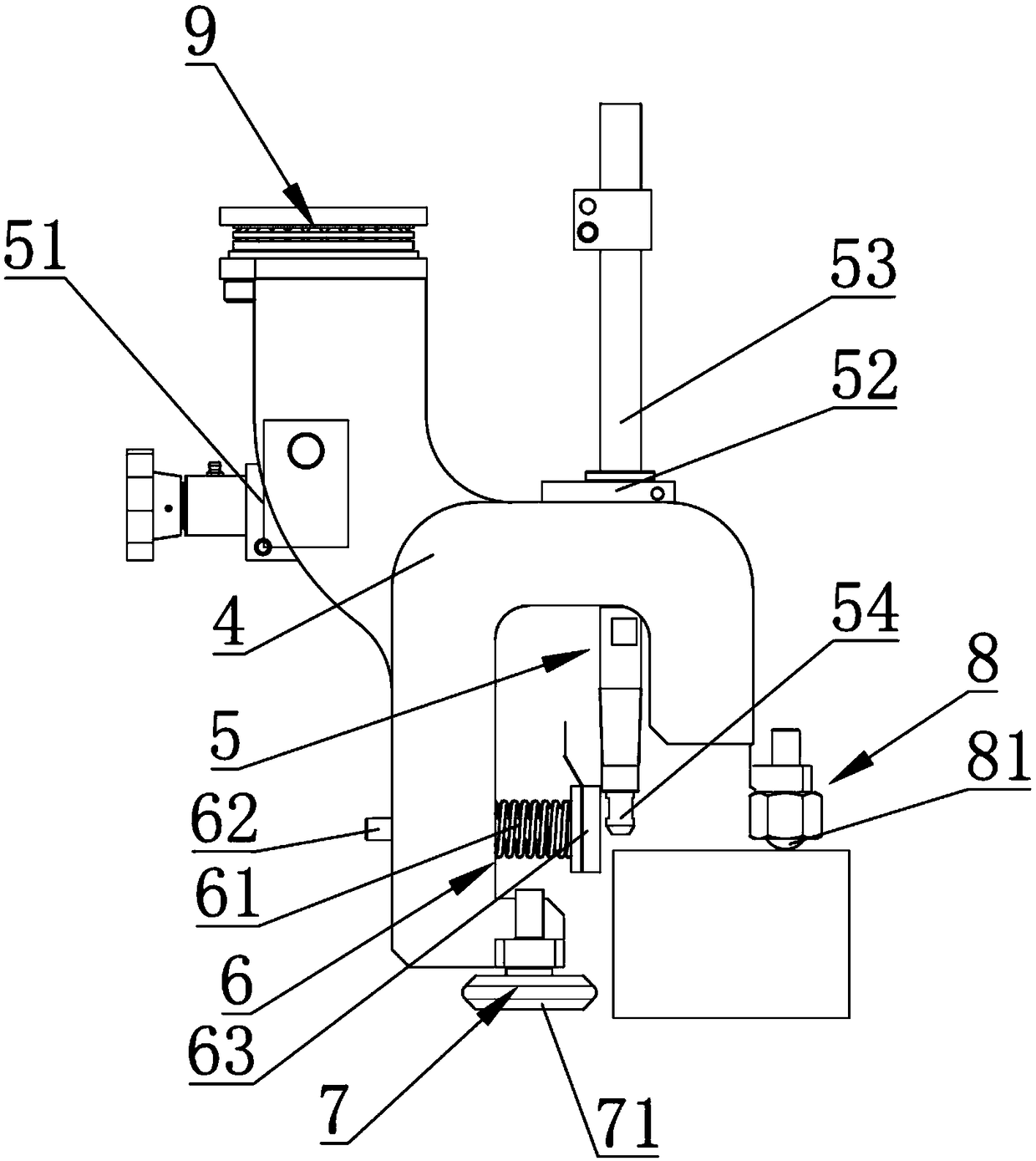

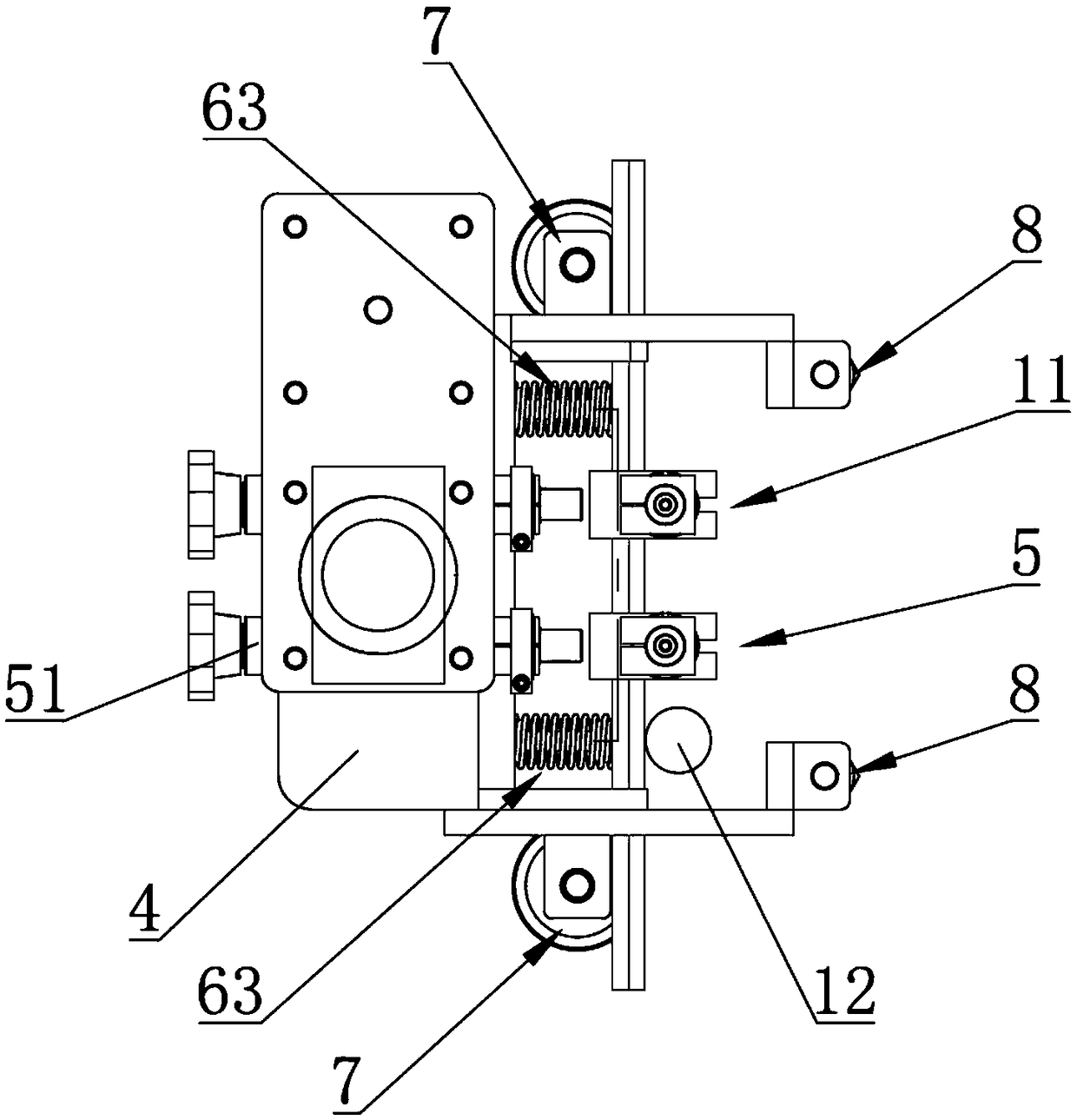

[0032] refer to Figure 1 ~ Figure 3 , the present embodiment provides a box girder welding equipment, including sequentially connected X-axis moving device 1, Y-axis moving device 2, Z-axis moving device 3, mounting frame 4 and installed on the mounting frame 4 for box-shaped The welding device 5 for beam welding, the mounting frame 4 is equipped with a baffle plate 63 assembly 6 for welding the box girder side plate and the panel, the welding device 5 is arranged on one side of the baffle plate 63 assembly 6, and the mounting frame 4 is installed There is a first pressure measuring component 7 for measuring the pressure on the side plate of the box girder in contact with the panel and a second pressure measuring component 8 for measuring the pressure on the side plate of the box girder in contact with the side plate, and the Y-axis moving device 2 is set There is a welding wire feeding device 10 for feeding welding wire to the welding device 5; it also includes a control dev...

Embodiment 2

[0050] refer to Figure 4 , The difference between this embodiment and Embodiment 1 is that the X-axis moving device 1 is not included, and the number of other devices is two groups, and the two sides of the box girder are welded at the same time to improve the welding efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com