Patents

Literature

46results about How to "No manual welding required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

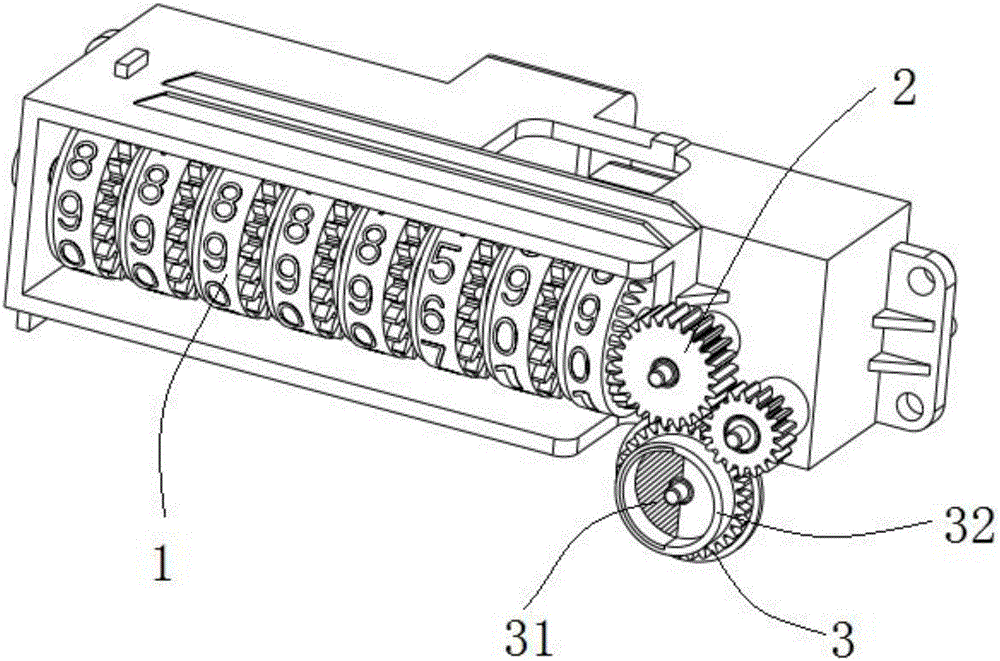

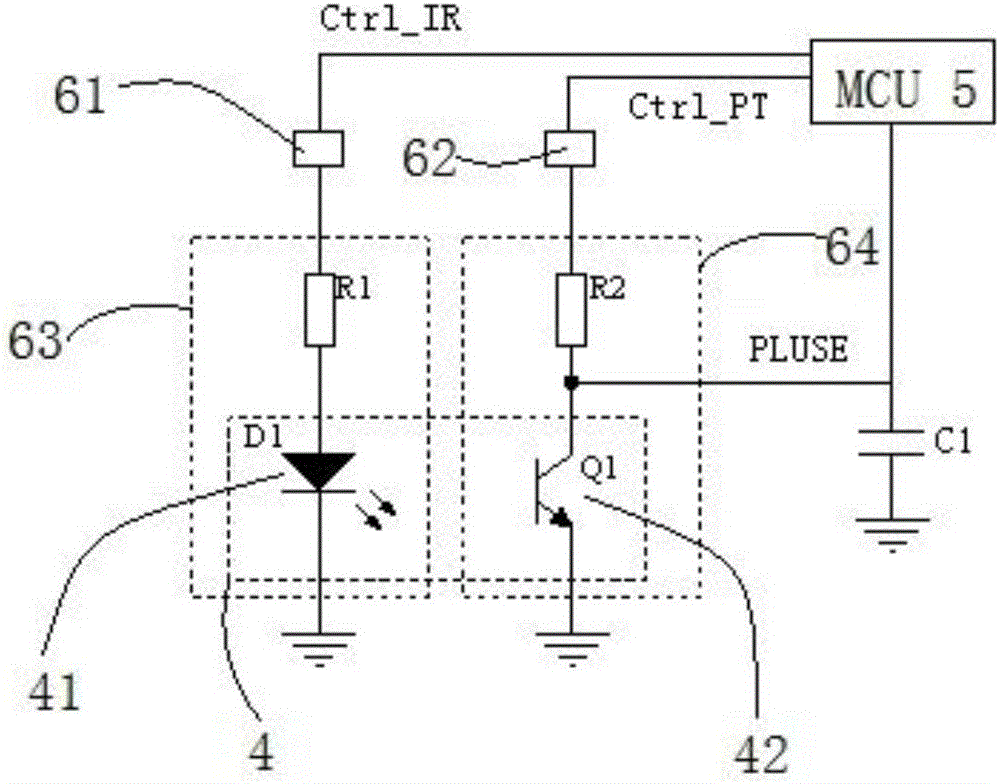

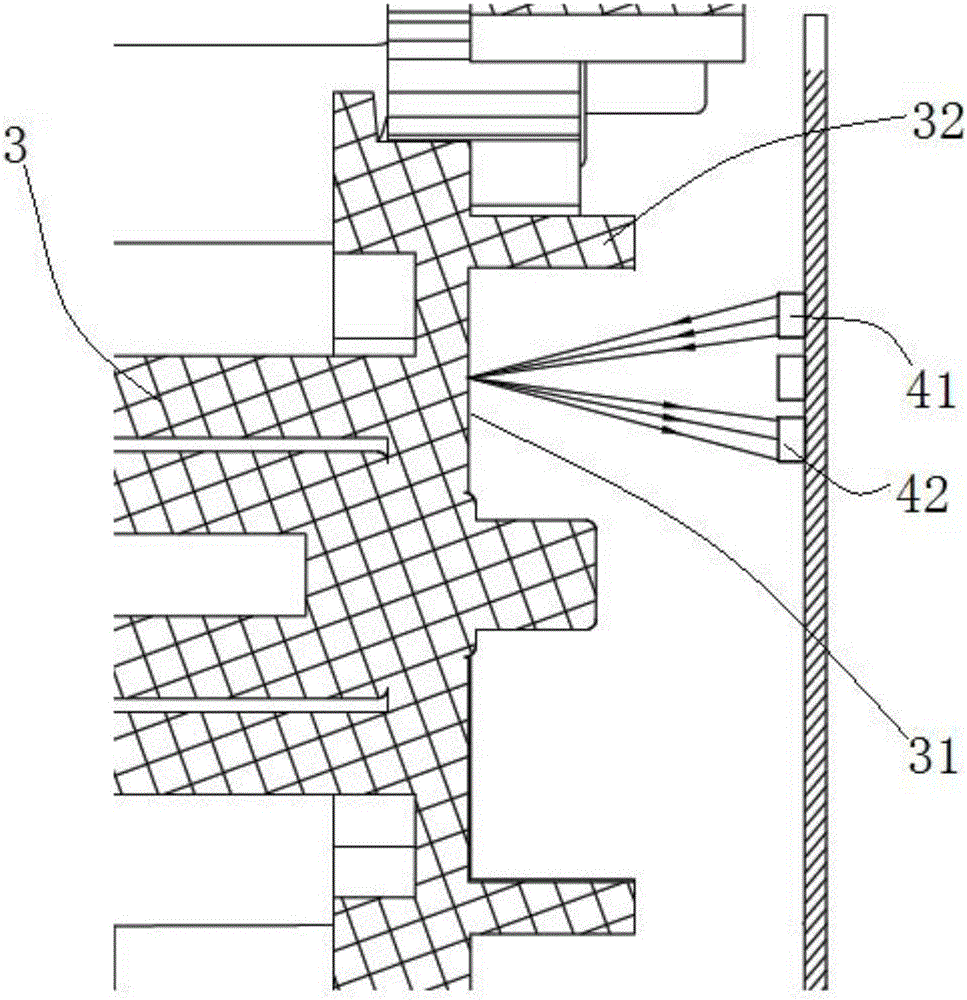

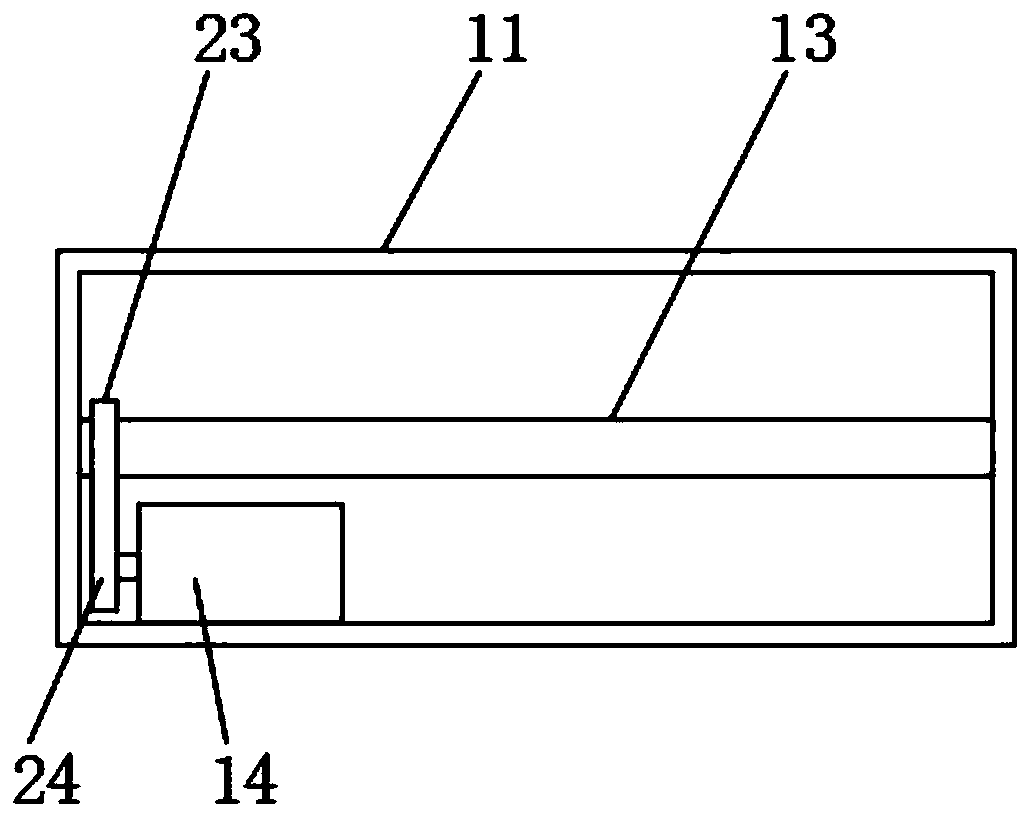

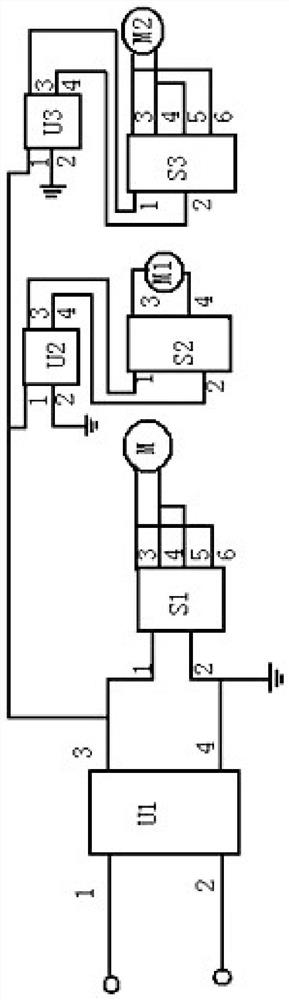

Novel pulse metering device in fuel gas meter end and metering method

InactiveCN106643951AReduce emission currentImprove reliabilityVolume indication and recording devicesSignal processingFuel gas

The invention discloses a novel pulse metering device in a fuel gas meter end and a metering method, and relates to the technical field of fuel gas metering devices. The novel pulse metering device in the fuel gas meter end mainly comprises a photoelectric sensor, an MCU, a counting gear and a transmission gear. The photoelectric sensor comprises a photoelectric transmitting tube and a photoelectric receiving tube, the photoelectric sensor is used as a metering switch, and the MCU is used for conducting on-off control and signal processing. According to the scheme, reflecting mediums are added to the counting gear and are used as on-off mediums of the photoelectric sensor, when the photoelectric sensor identifies a white medium, the photoelectric sensor outputs a voltage to the MCU, when the photoelectric sensor identifies a black medium, the photoelectric sensor outputs another voltage to the MCU, and then the MCU achieves a metering function by distinguishing signals of different voltages. According to the novel pulse metering device in the fuel gas meter end and the metering method, the novel metering device has the advantages of being accurate in metering, strong in anti-light capability, low in power dissipation and cost, simple in process, high in production efficiency, and strong in anti-interference capability.

Owner:GOLDCARD HIGH TECH

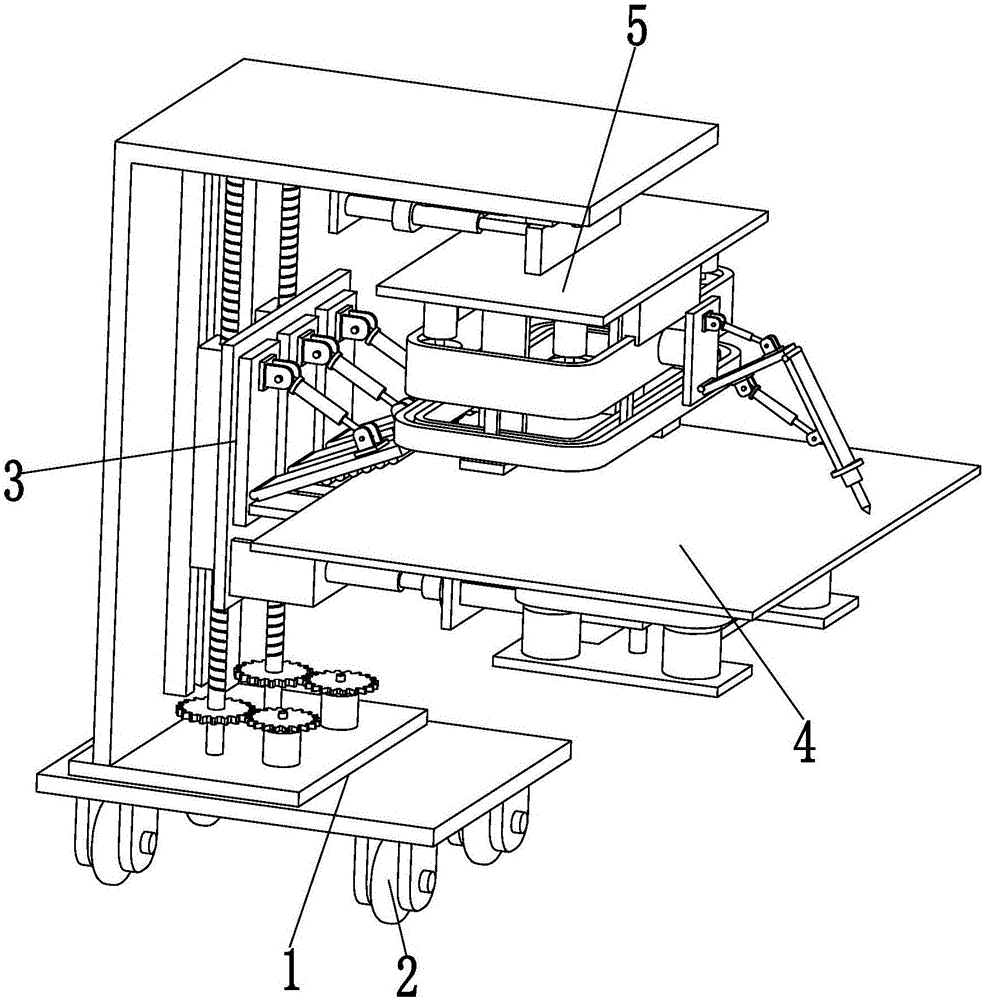

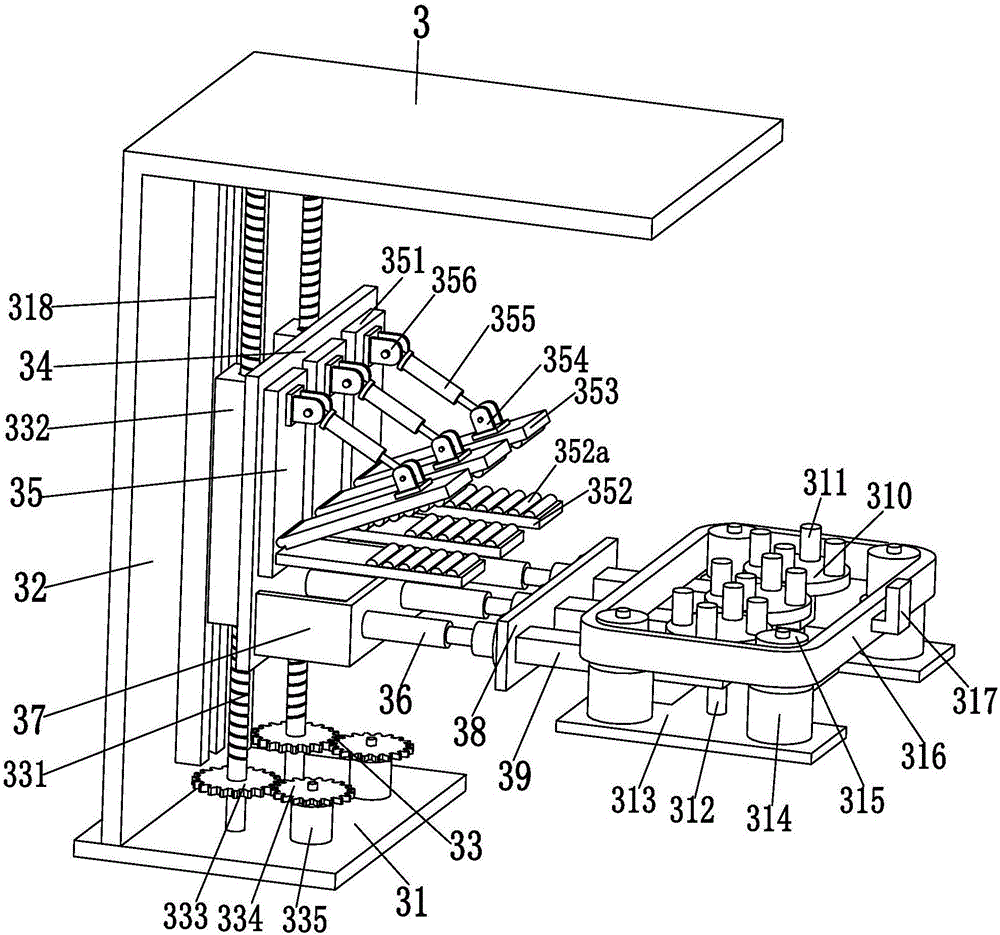

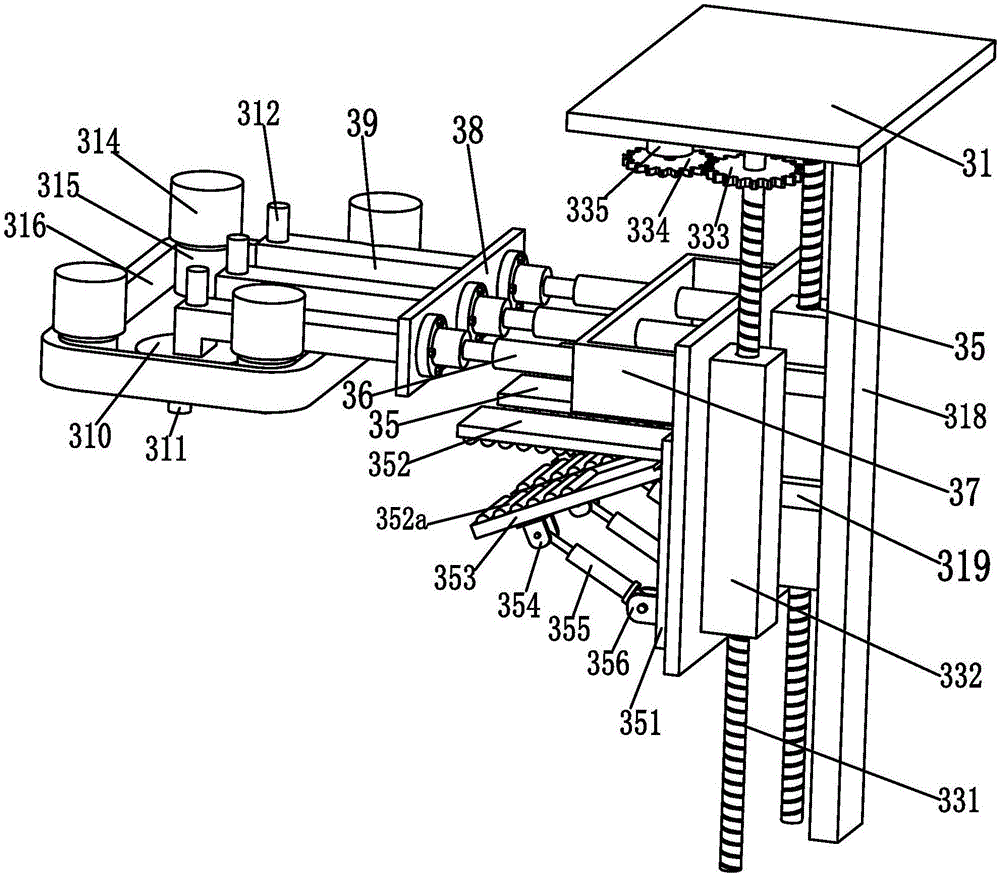

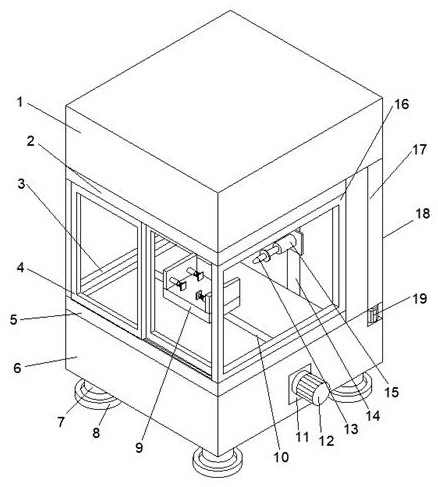

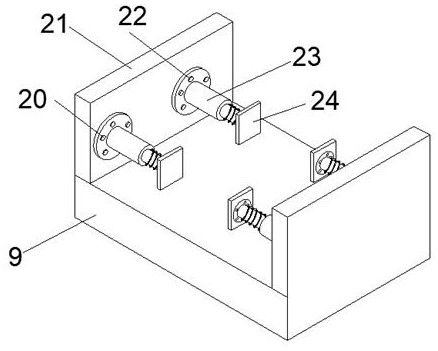

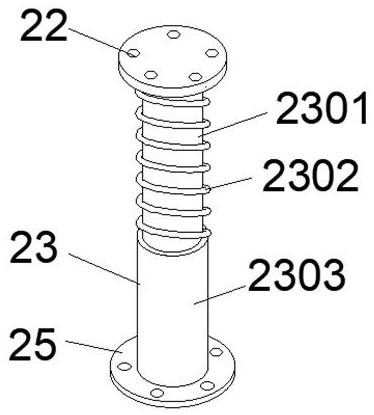

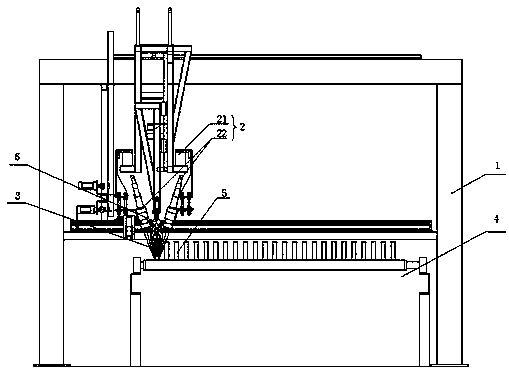

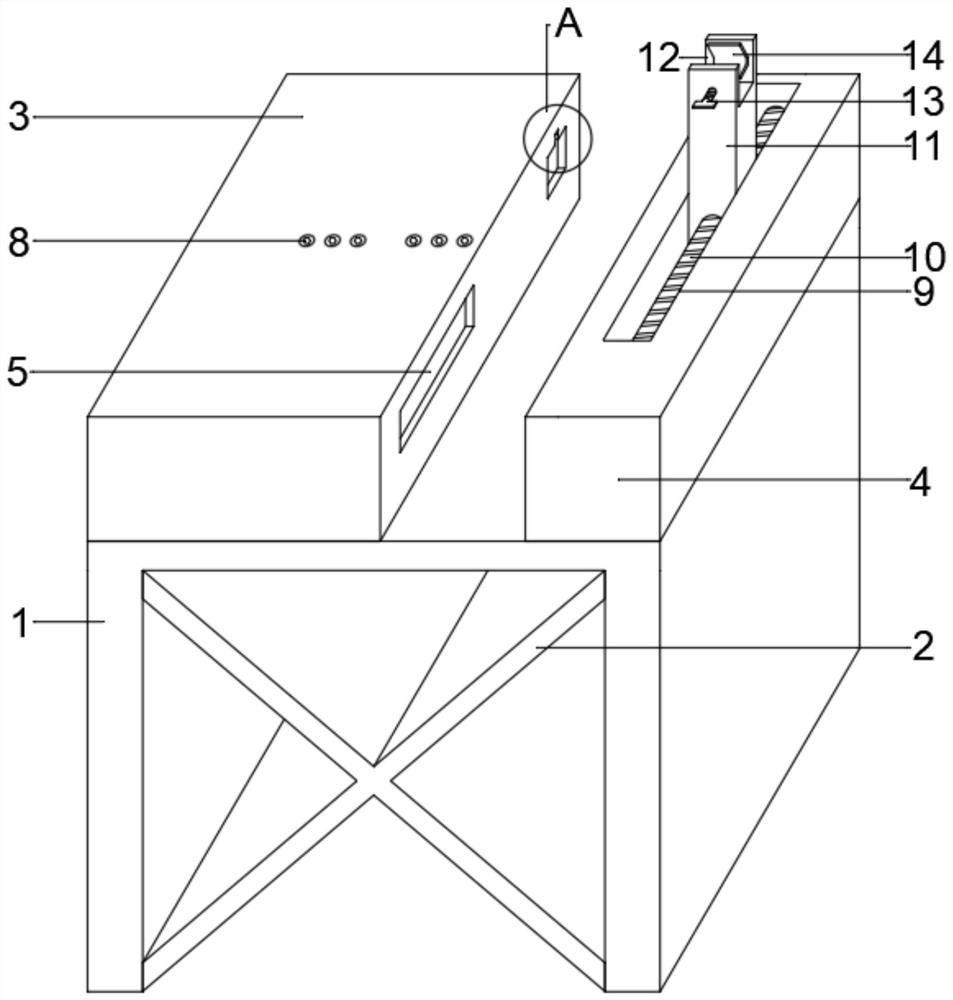

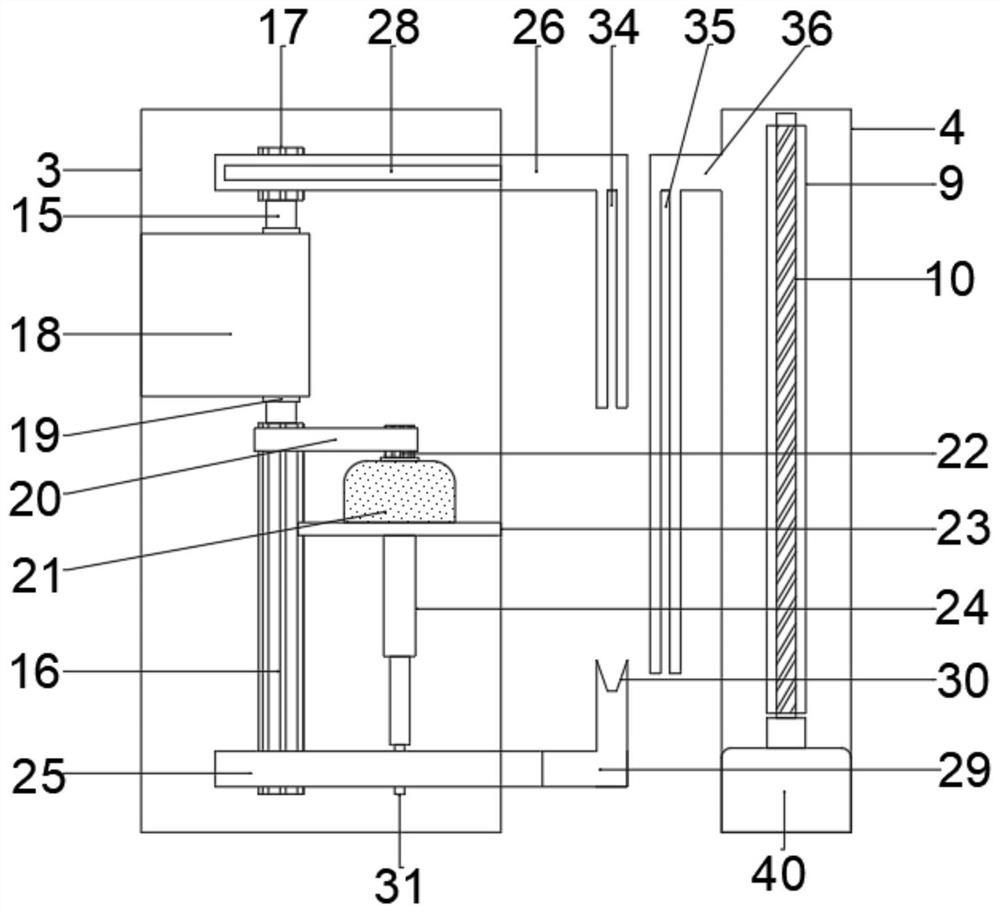

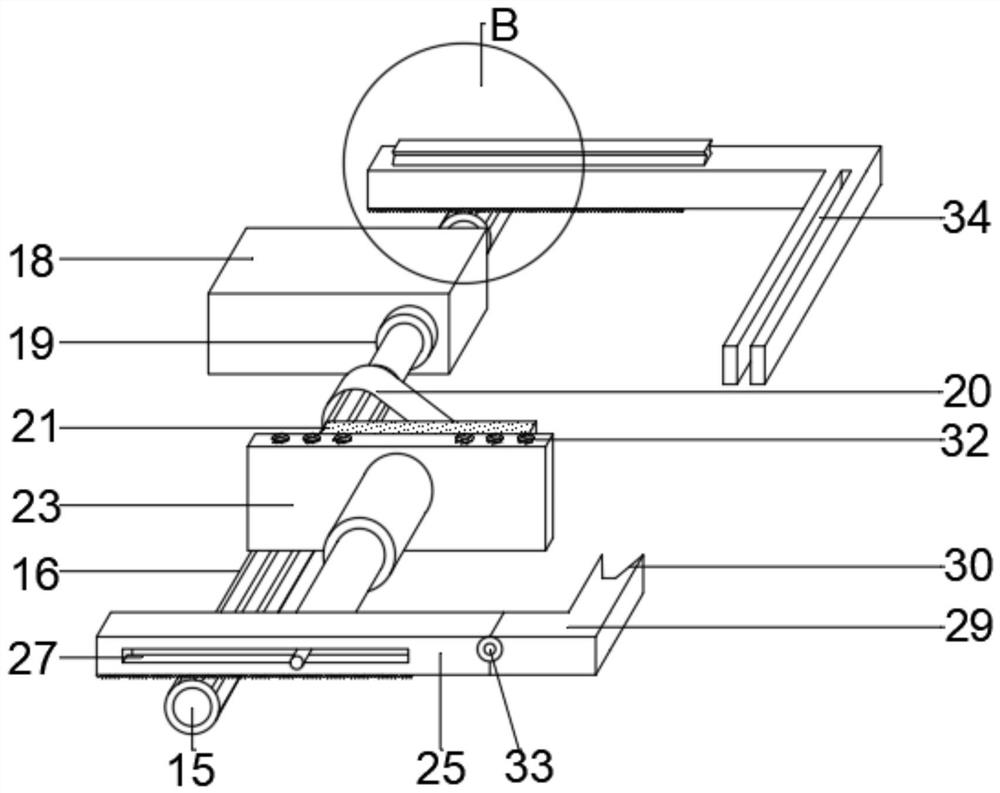

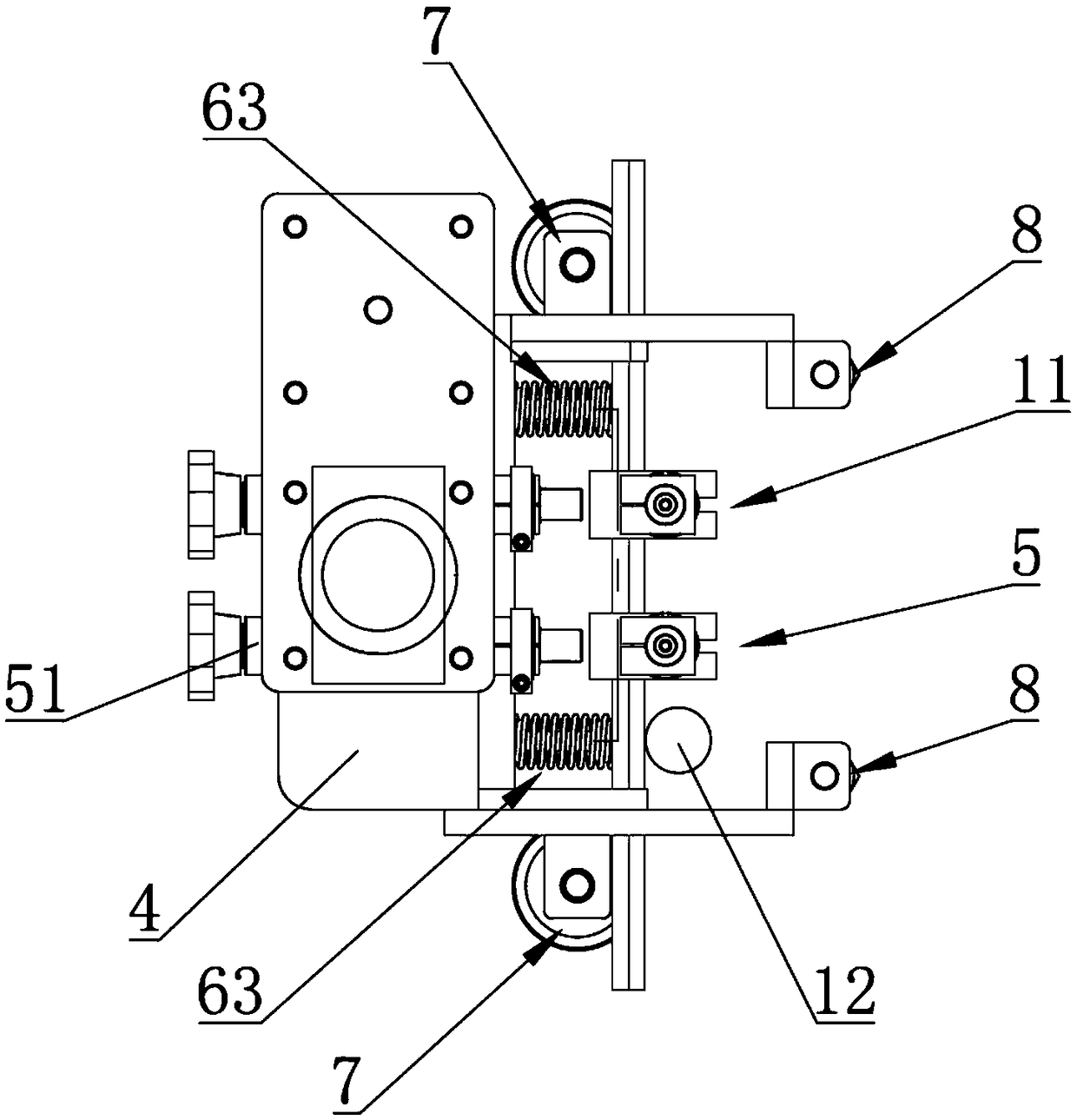

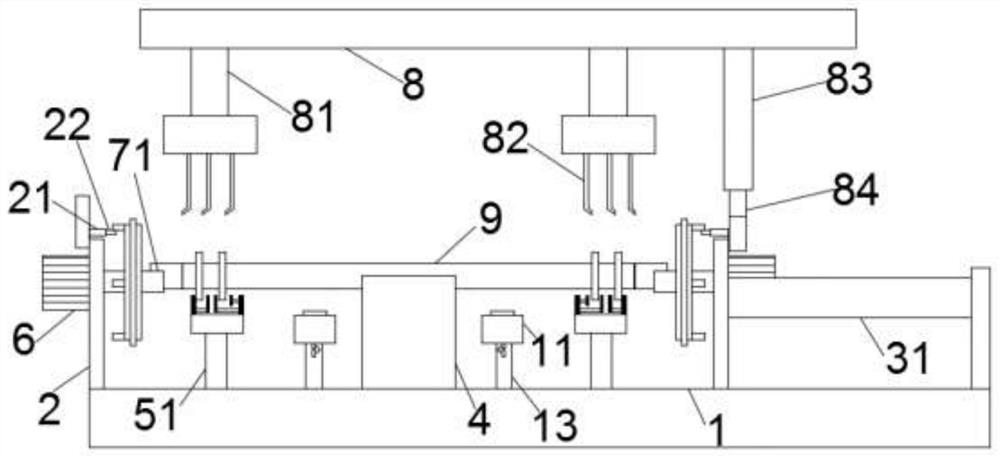

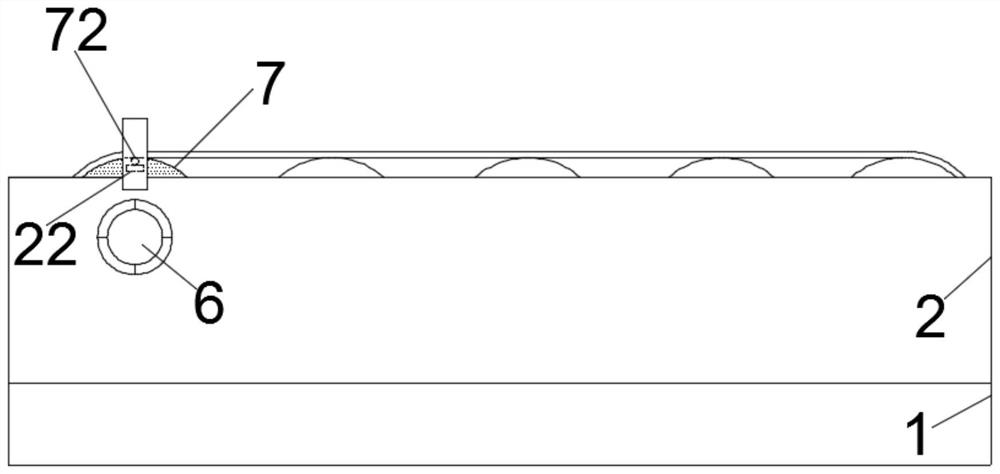

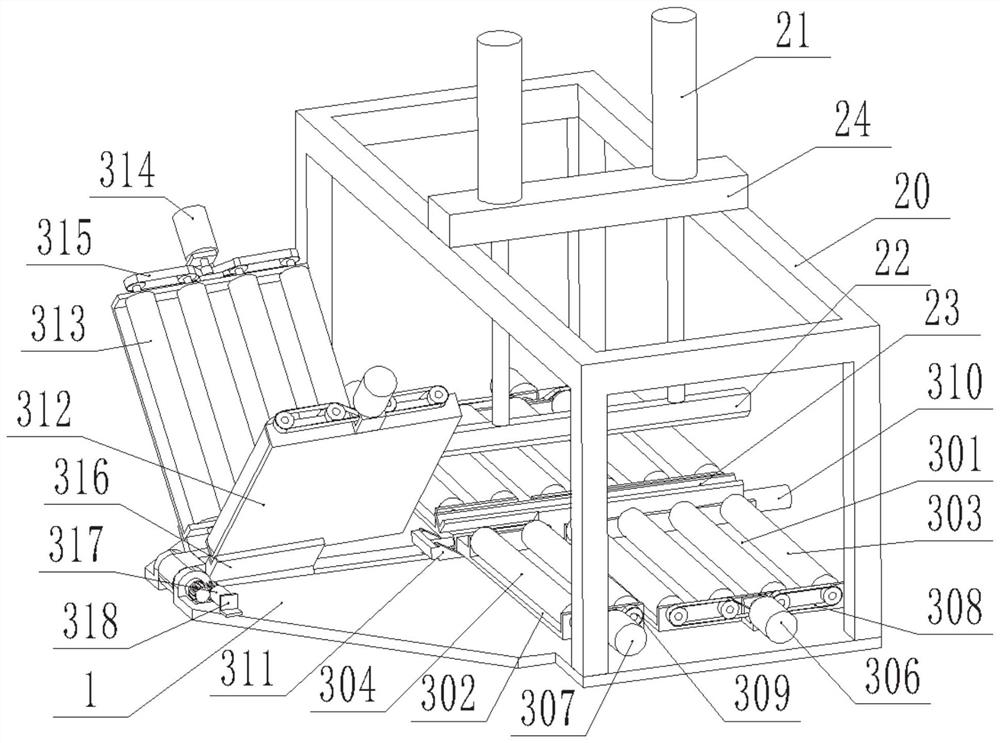

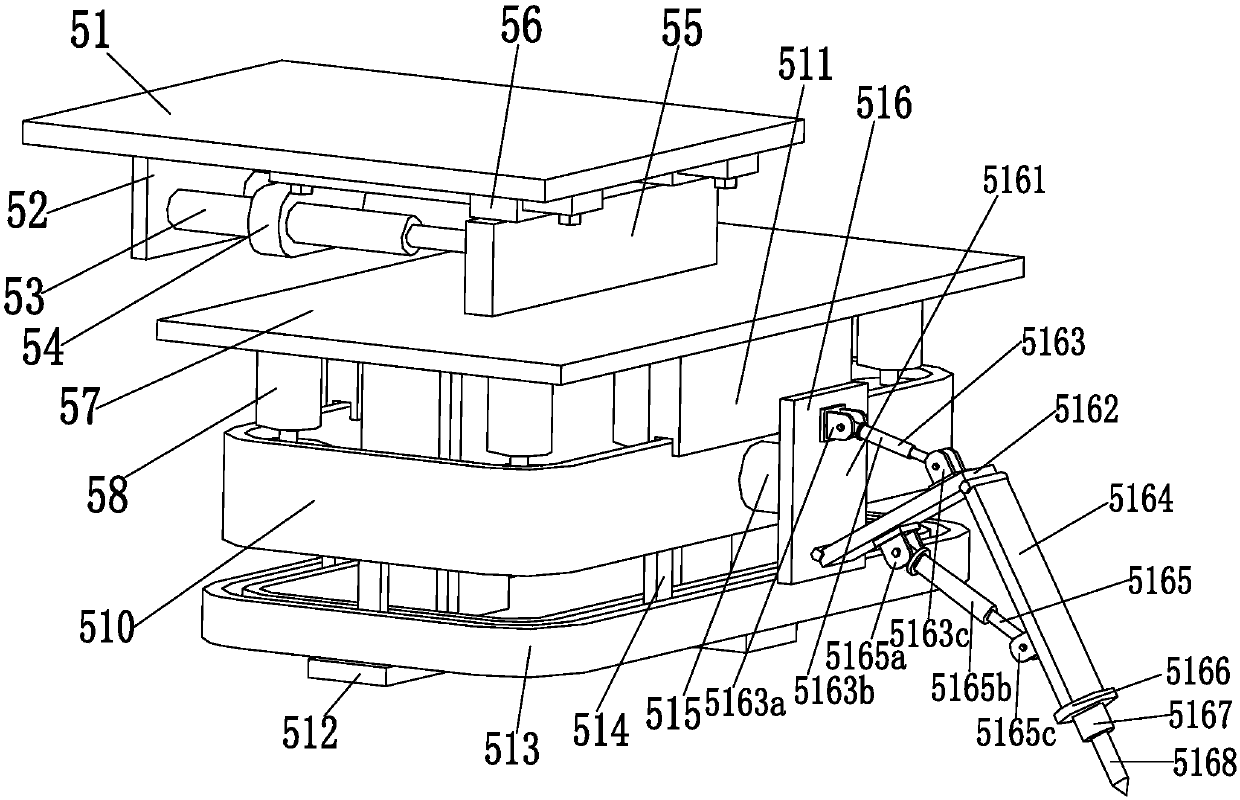

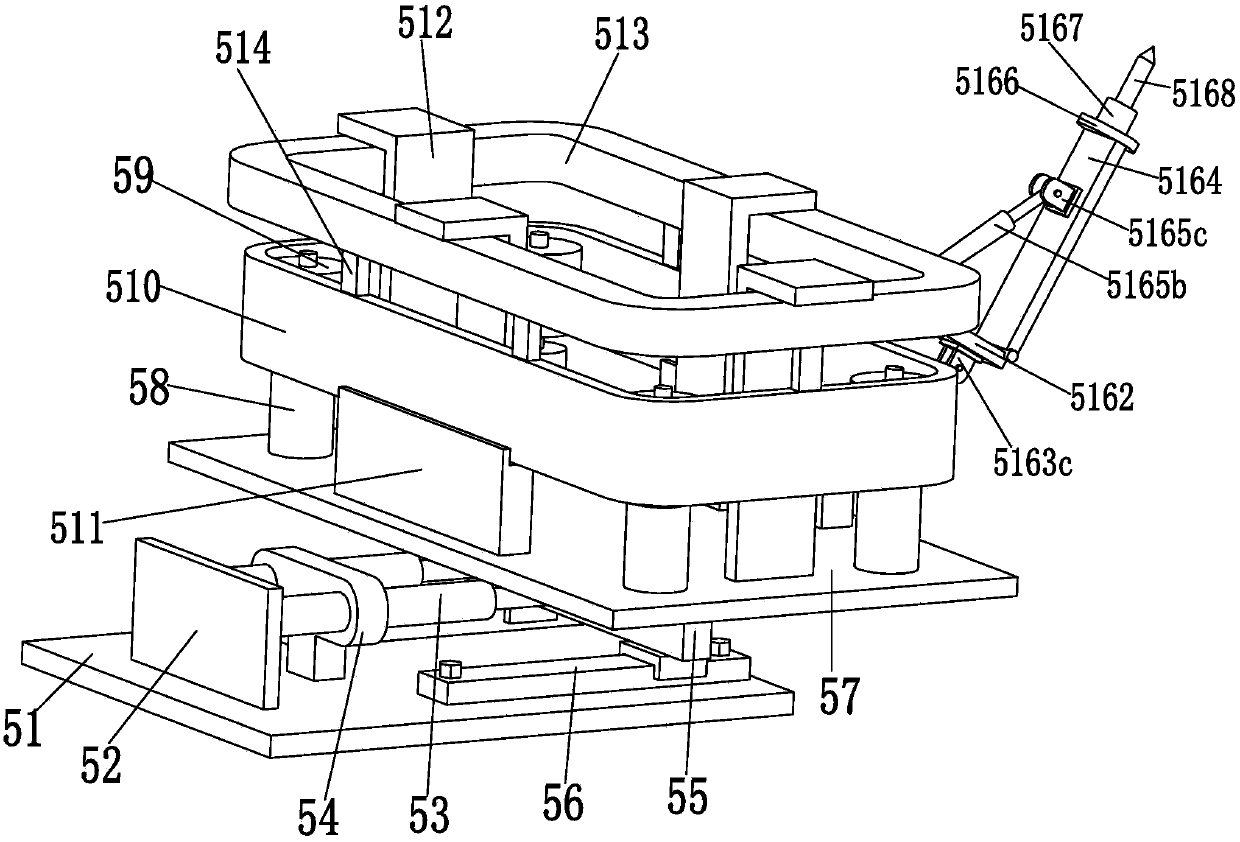

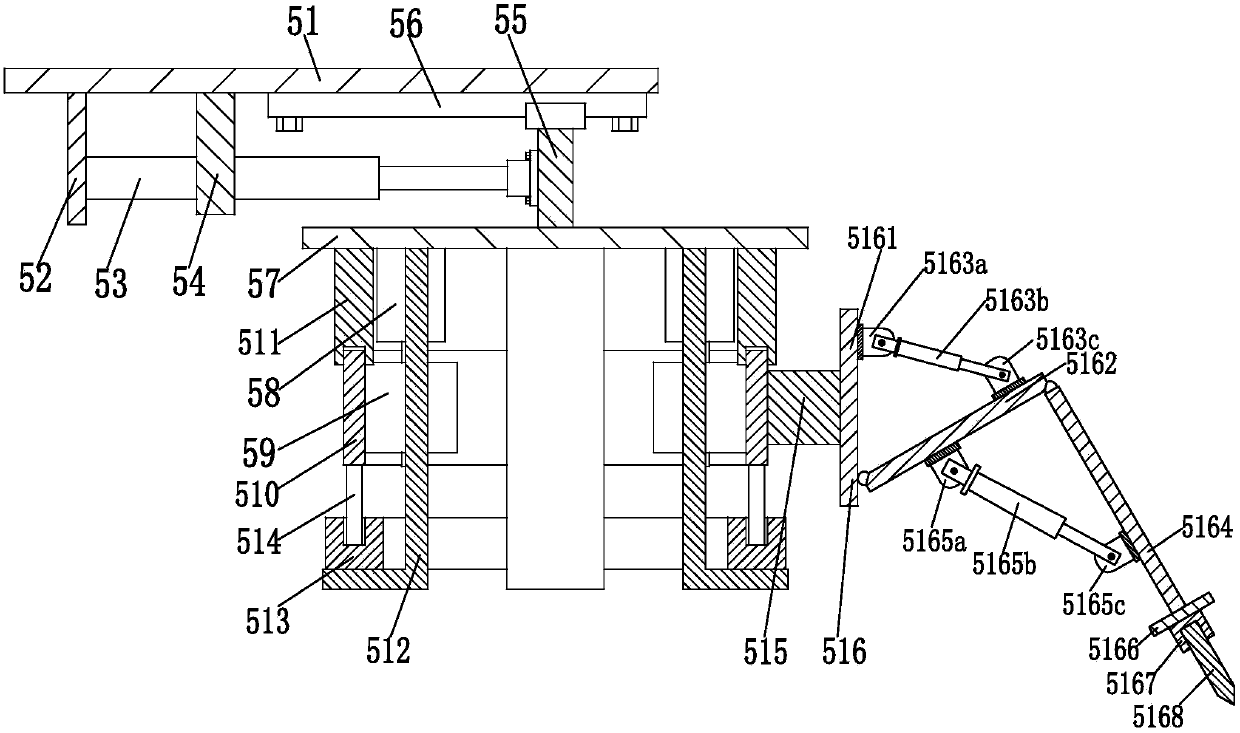

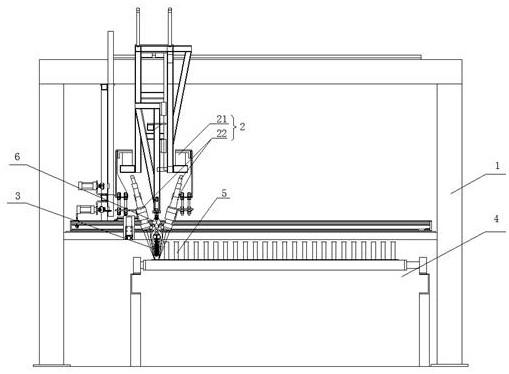

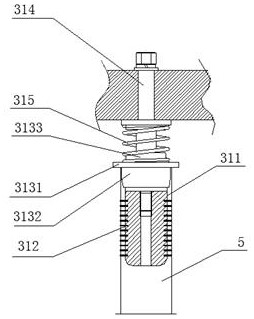

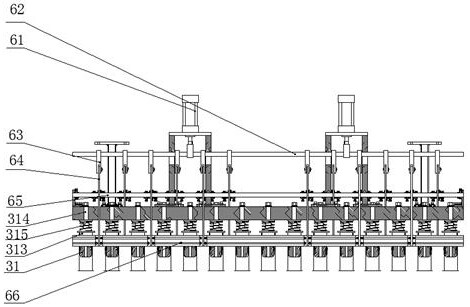

Clamping and welding equipment for partition board of power distribution cabinet

ActiveCN106312401AAchieve stable clamping support functionImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringElectric power

The invention relates to clamping and welding equipment for a partition board of a power distribution cabinet. The equipment comprises a base plate, wherein four universal wheels are symmetrically mounted on the lower end surface of the base plate. The clamping and welding equipment is moved to a required position through the four universal wheels, a clamping and supporting device is mounted on an upper end surface of the base plate, a partition board body is clamped on the clamping and supporting device, the clamping and supporting device can realize the stable clamping and supporting function of the partition board body, welding of the partition board body is facilitated, and a mobile welding device is mounted on the upper end surface of the clamping and supporting device and can realize the automatic and rapid welding function of the partition board body. Stable clamping and supporting and automatic and rapid welding functions of the partition board of the power distribution cabinet can be realized, and the clamping and welding equipment is easy and convenient to operate without manual operation and has the advantages that manual positioning clamping is not required, the mounting speed is high, the clamping effect is good, the stable supporting effect is good, the working efficiency is high, manual welding is not required, the welding speed is high, the welding quality is good, the welding efficiency is high and the like.

Owner:YANCHENG POWER SUPPLY CO STATE GRID JIANGSU ELECTRIC POWER CO +4

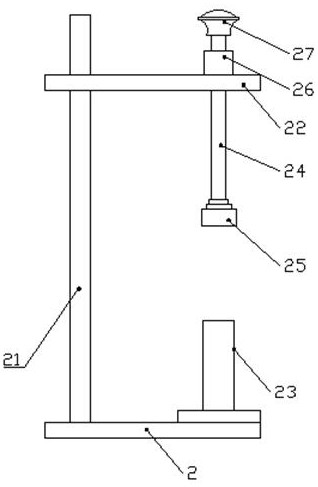

Welding device in pipe rack processing assembly

InactiveCN110000450AAchieve lateral movementAchieve vertical movementWelding/cutting auxillary devicesArc welding apparatusHydraulic cylinderGear drive

The invention discloses a welding tool in pipe rack processing assembly. The welding tool comprises a bottom plate, supporting columns and a transverse shaft, wherein the two sides of the top of the bottom plate are separately equipped with the supporting columns; the bottom ends of the two supporting columns are welded and fixed on the top surface of the bottom plate; the transverse shaft is arranged at the top-end position between the two supporting columns; a box body is arranged on the bottom plate between the two supporting columns; the output end of a second motor drives a drive gear torotate; the drive gear drives a transmission gear to rotate through a chain; the transmission gear drives a lead screw to rotate; the lead screw is in threaded connection to a nut base, so that a movable block moves along the lead screw, and therefore, longitudinal movement of a welding head is realized; and finally, a hydraulic cylinder controls a piston pushing rod to lift, so that movement, ina vertical direction, of the welding head is realized, and the welding head is in contact with a welding point; and the output end of a third motor drives a rotary shaft to rotate, so that a pipe clamp rotates, and therefore, integral welding work of the pipe is accomplished, manual welding is not needed, manual errors are avoided, and welding precision is improved.

Owner:安徽凯贝耐特钣金科技有限公司

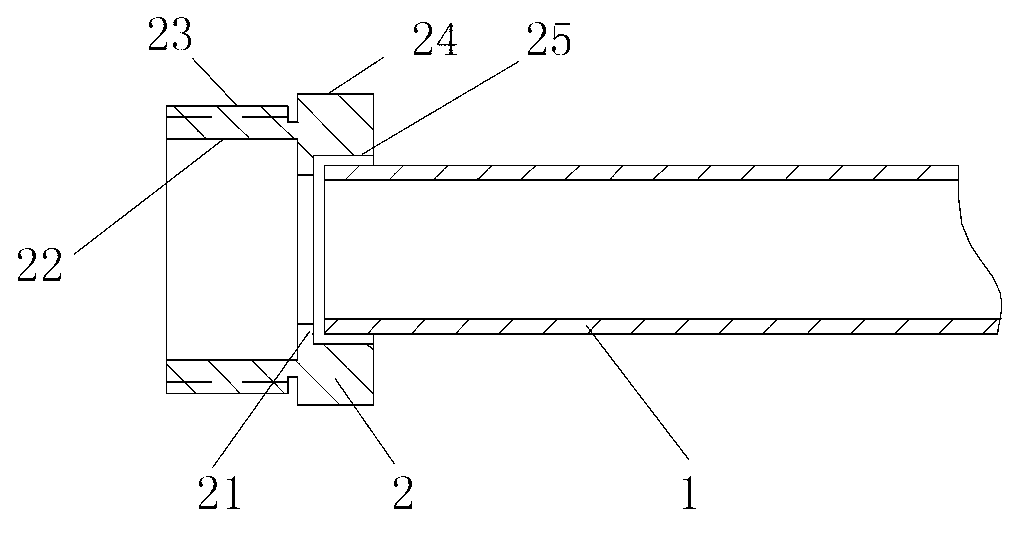

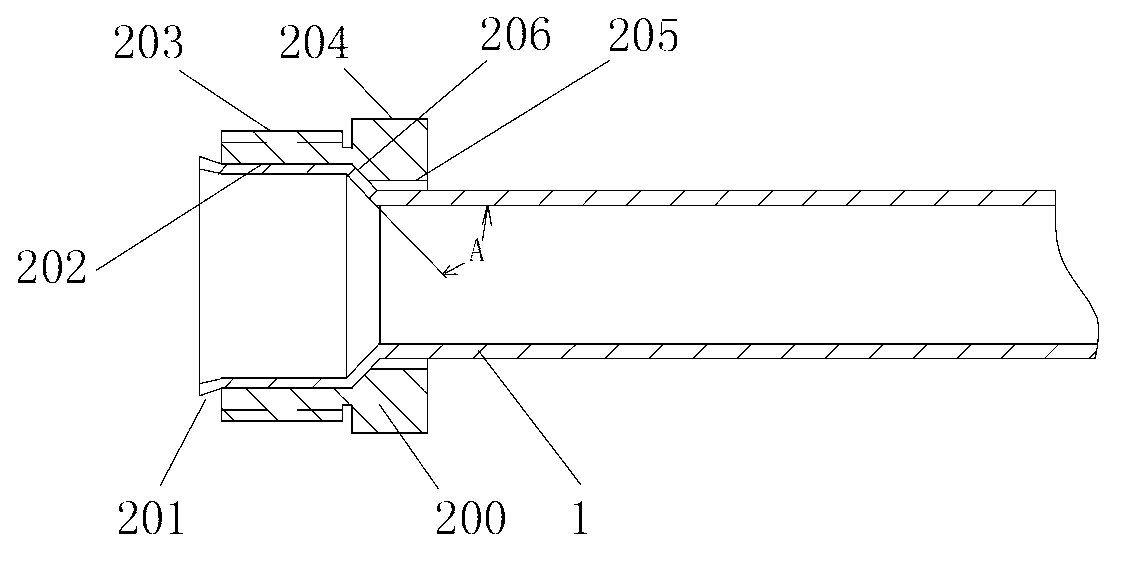

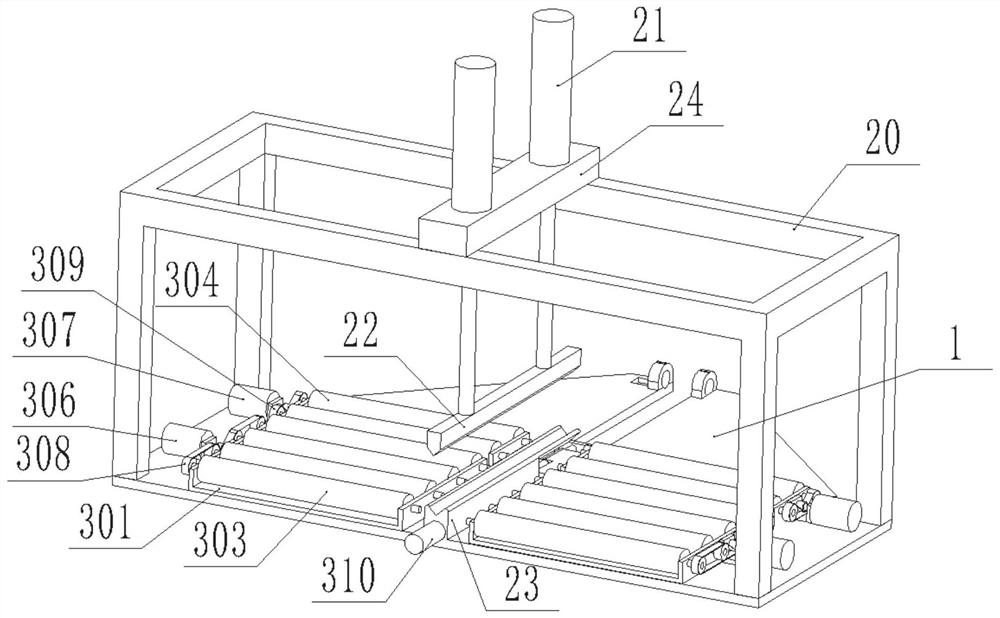

Non-welded pipeline joint of automobile air conditioner and machining method of non-welded pipeline joint

InactiveCN103016862ALow costNo manual welding requiredJoints with sealing surfacesScrew threaded jointsAutomobile air conditioningNitrogen

The invention discloses a non-welded pipeline joint of an automobile air conditioner and a machining method of a non-welded pipeline joint. The non-welded pipeline joint comprises a hollow tube and an external threaded joint, wherein the head part of the external threaded joint is an external thread; the tail part of the external threaded joint is hexagonal; the front part in the external threaded joint is a big through hole; the tail part in the external threaded joint is a small through hole; the big through hole is connected with the small through hole through a conical hole; and the external diameter of the head part of the hollow tube is as same as the diameter of the big through hole. An angle between the conical hole and the axis of the hollow tube is 30-60 degrees. The angle between the conical hole and the axis of the hollow tube is preferably 45 degrees. A flared opening is turned over outwards from the open end of the big through hole. The invention further discloses a machining method of the non-welded pipeline joint of the automobile air conditioner. The non-welded pipeline joint of the automobile air conditioner and the machining method of the non-welded pipeline joint, disclosed by the invention, have the benefits as follows: manual welding is not needed; a molded product does not need to be washed by special medicinal liquid and only needs to be degreased by using common medicinal liquid; nitrogen detection is not needed for the molded product; no leakage is caused; and the cost can be saved.

Owner:ZHEJIANG PULISI AUTO PARTS

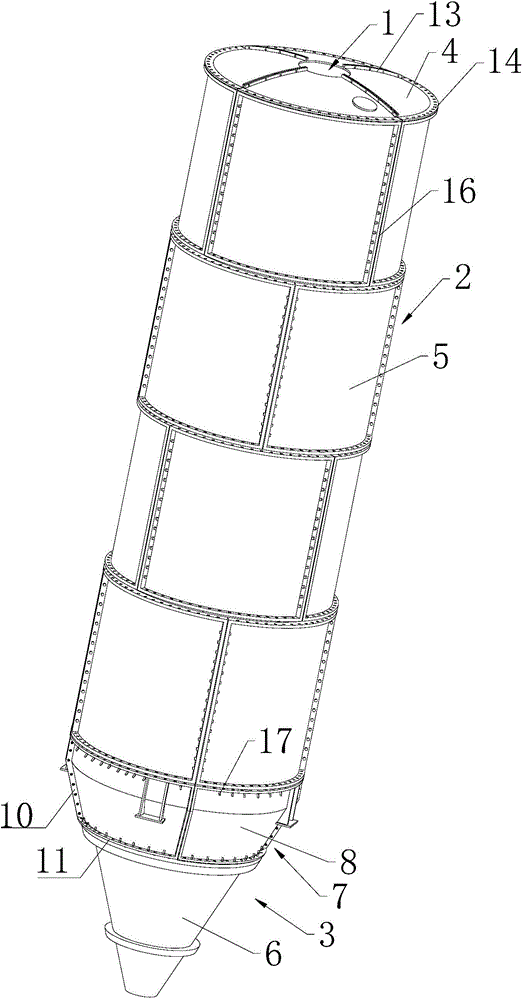

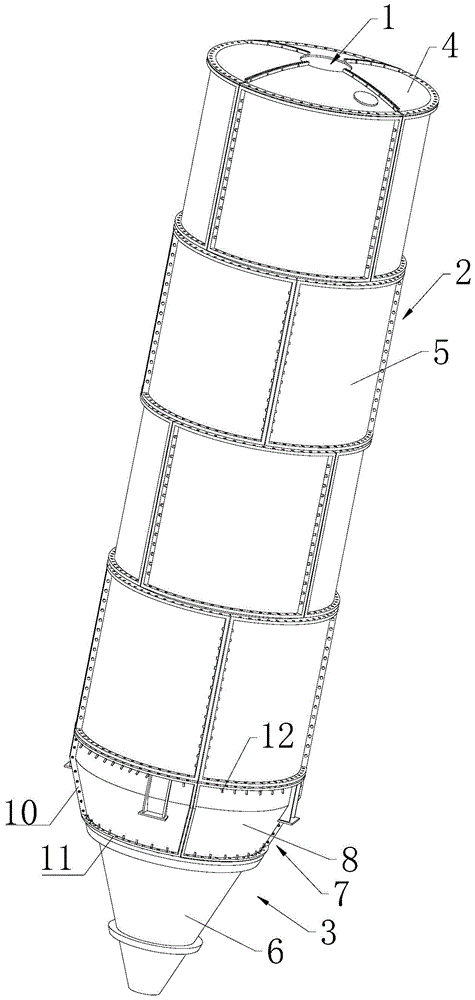

Cement bin and manufacturing process thereof

The invention discloses a cement bin and a production process thereof. The cement bin sequentially comprises an upper cone, a middle barrel and a lower cone; the upper cone is formed by assembling a plurality of upper cone splicing modules; the middle barrel is formed by assembling a plurality of middle barrel splicing modules; the lower cone comprises a tail end cone and at least one cone barrel; the cone barrel comprises a plurality of cone barrel splicing modules; a plurality of cone barrel splicing modules are assembled to form the cone barrel; both left and right sides of each cone barrel splicing module body are respectively provided with cone barrel strip flanges which are integrally formed by a hydraulic press; each two adjacent cone barrel strip flanges are installed together; both upper and lower ends of each cone barrel splicing module body are welded with cone barrel arc flanges fixedly connected with the upper end of the middle barrel. According to the invention, the production period is greatly shortened, cost is greatly reduced, all bin bodies are consistent in size, the cement bin can be produced in batches, standardization is implemented, and the cement bin is convenient to transport and can be rapidly assembled in field.

Owner:潍坊金河机械有限公司

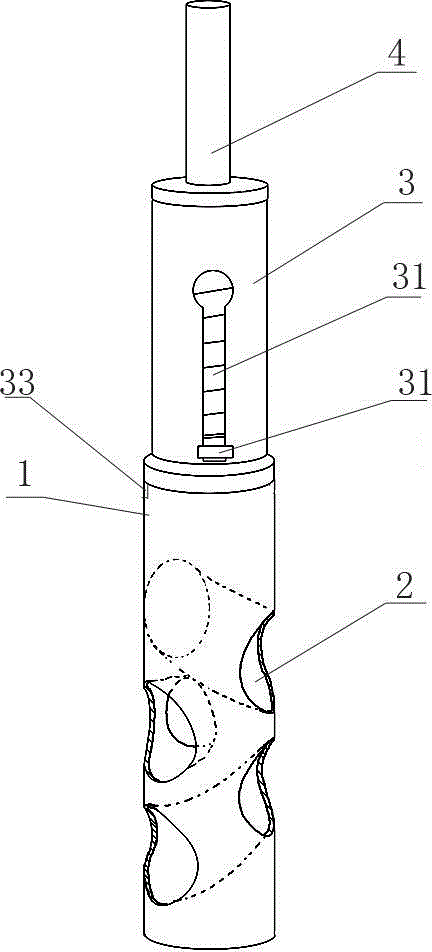

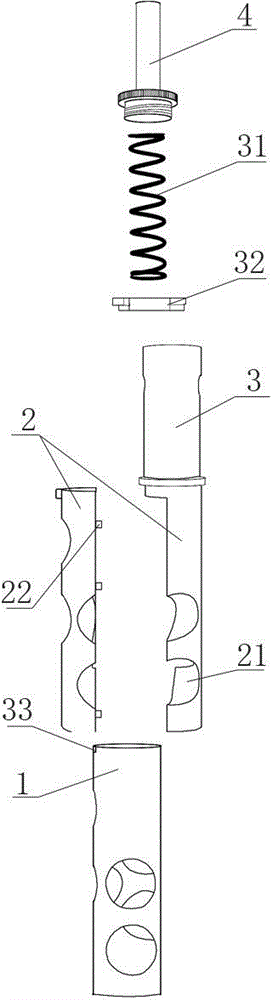

Brass-wind instrument piston and manufacturing method thereof

ActiveCN104392708ANot easy to be damaged by corrosionHigh installation concentricityWind musical instrumentsKey pressingMechanical engineering

The invention relates to a brass-wind instrument piston and a manufacturing method thereof. The piston comprises an outer tube body, a core and a spring tube, wherein the outer tube body is a circular metal barrel; both the core and the spring tube are integrally manufactured through plastic; the core is a plastic cylinder body and equipped with a plurality of ventilating holes; the plastic cylinder body is divided into two longitudinal parts from the middle part, and a plurality of splicing positioning pins are arranged between the two half cylinder bodies; the spring tube is cylinder-shaped, and a spring and a spring clamp are arranged in the cylinder; a piston handle is arranged at the upper end of the spring tube. The brass-wind instrument piston has the advantages that corrosion is uneasily caused, the weight is light, the key is power-saving, the production is accurately located, the performing effect can be improved, and the durability is ensued. The manufacturing method of the brass-wind instrument piston has the advantages of being simple in process, high in yield and high in production efficiency.

Owner:武强金音教育发展股份有限公司

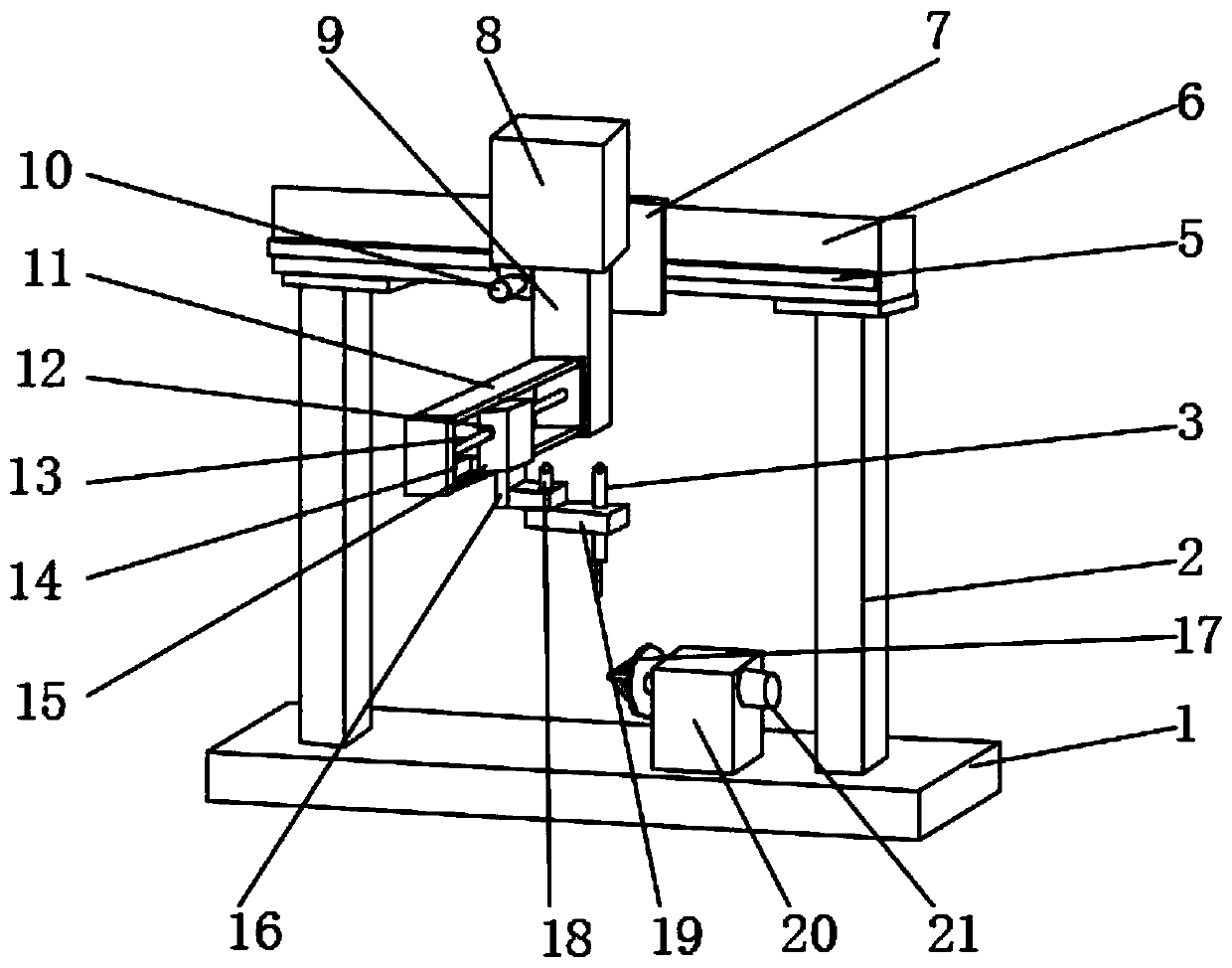

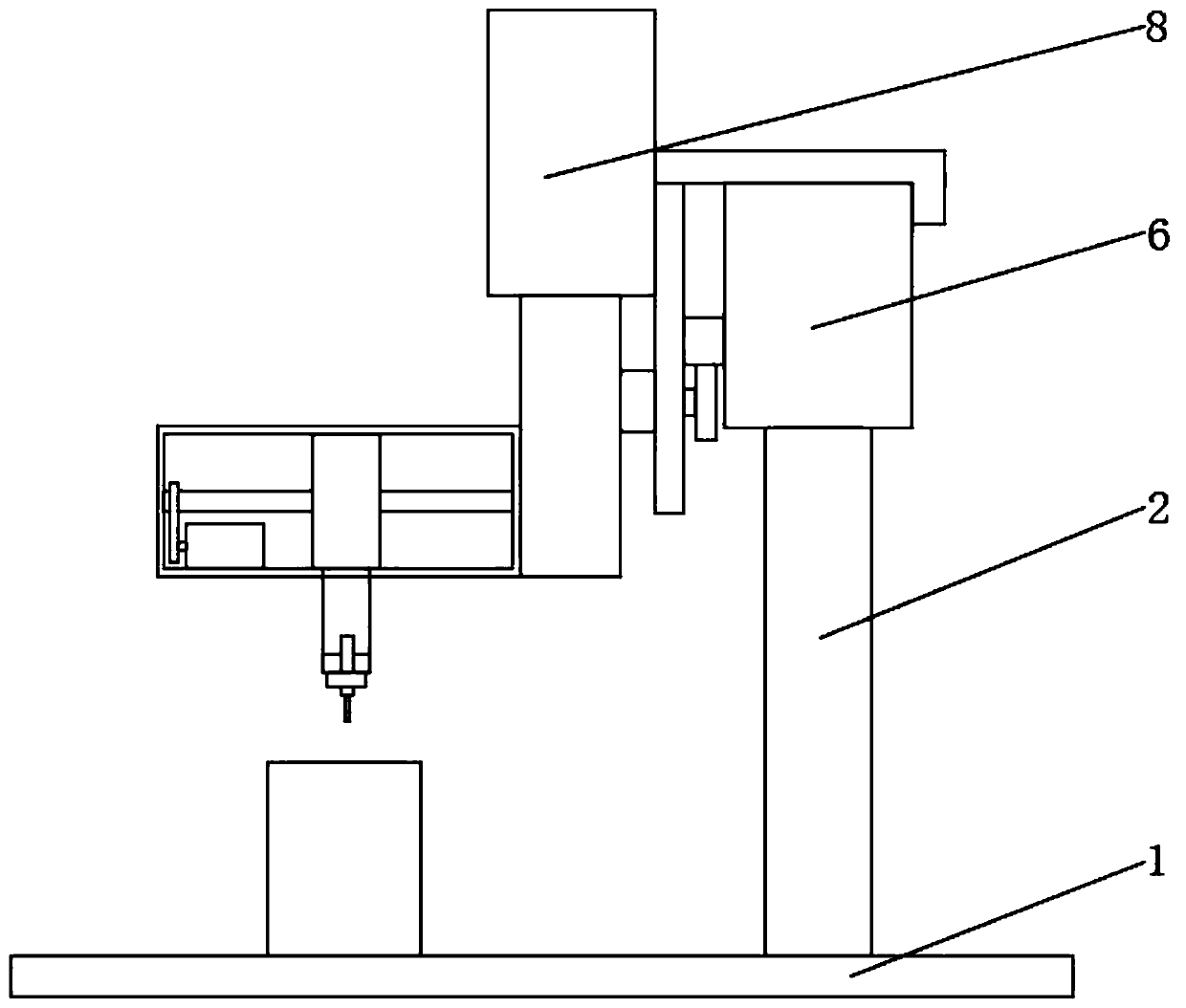

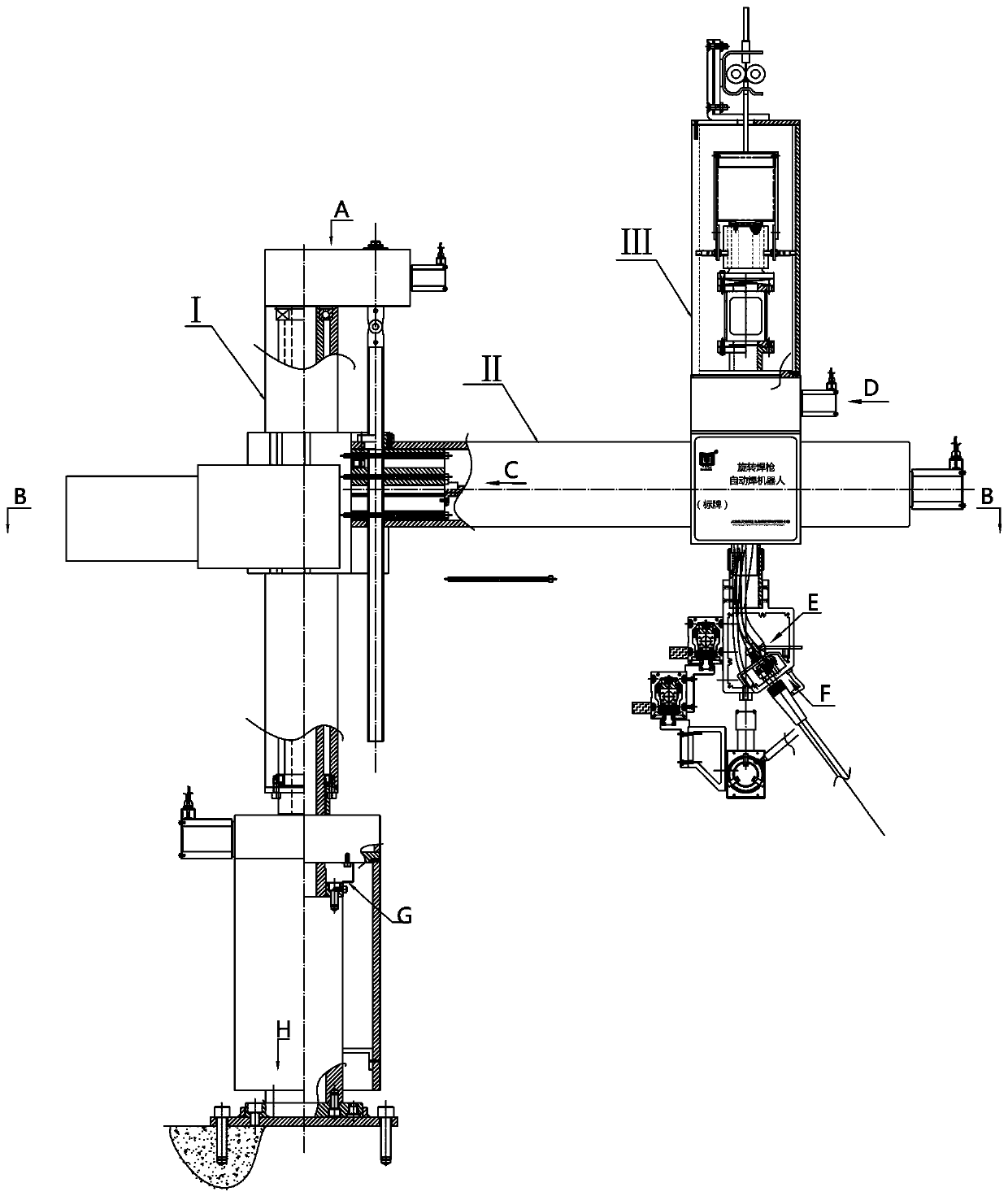

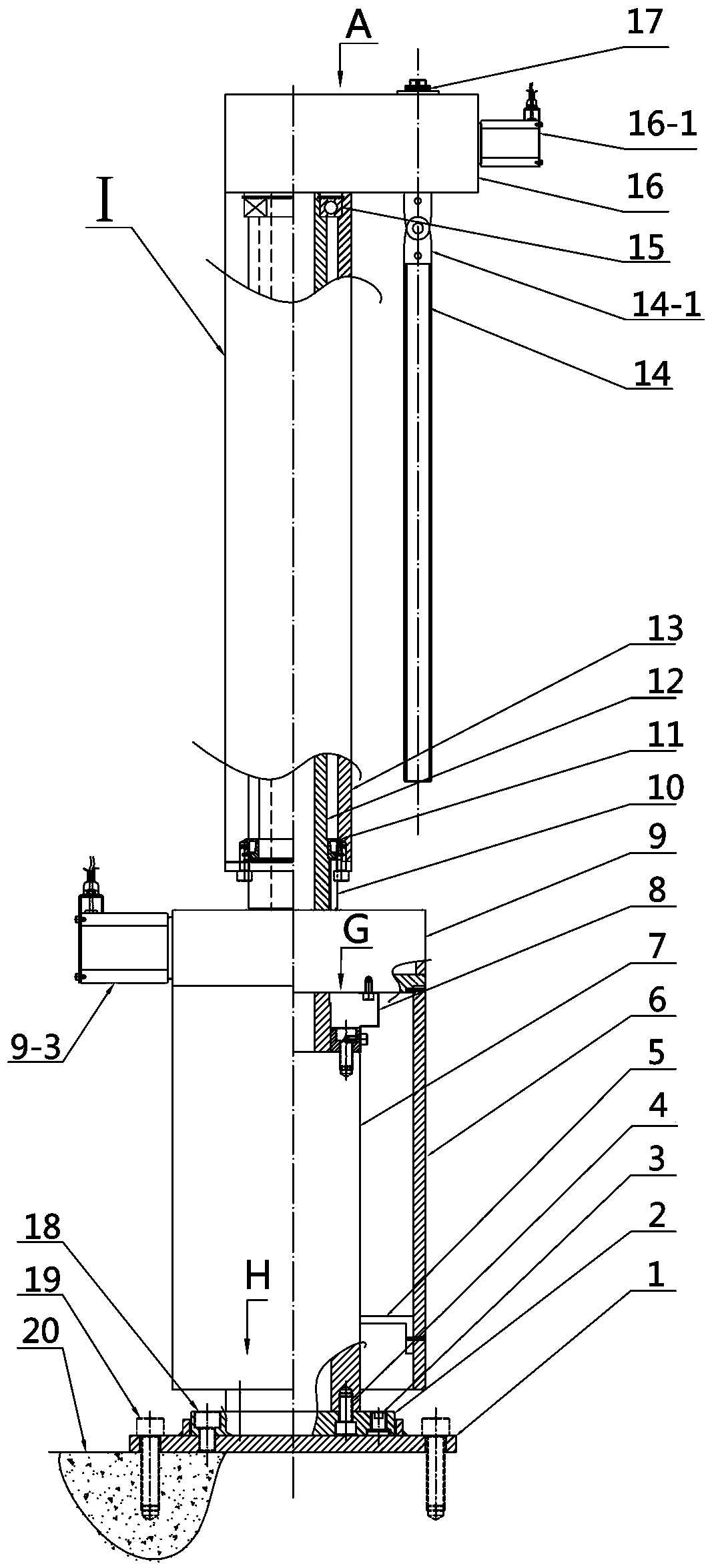

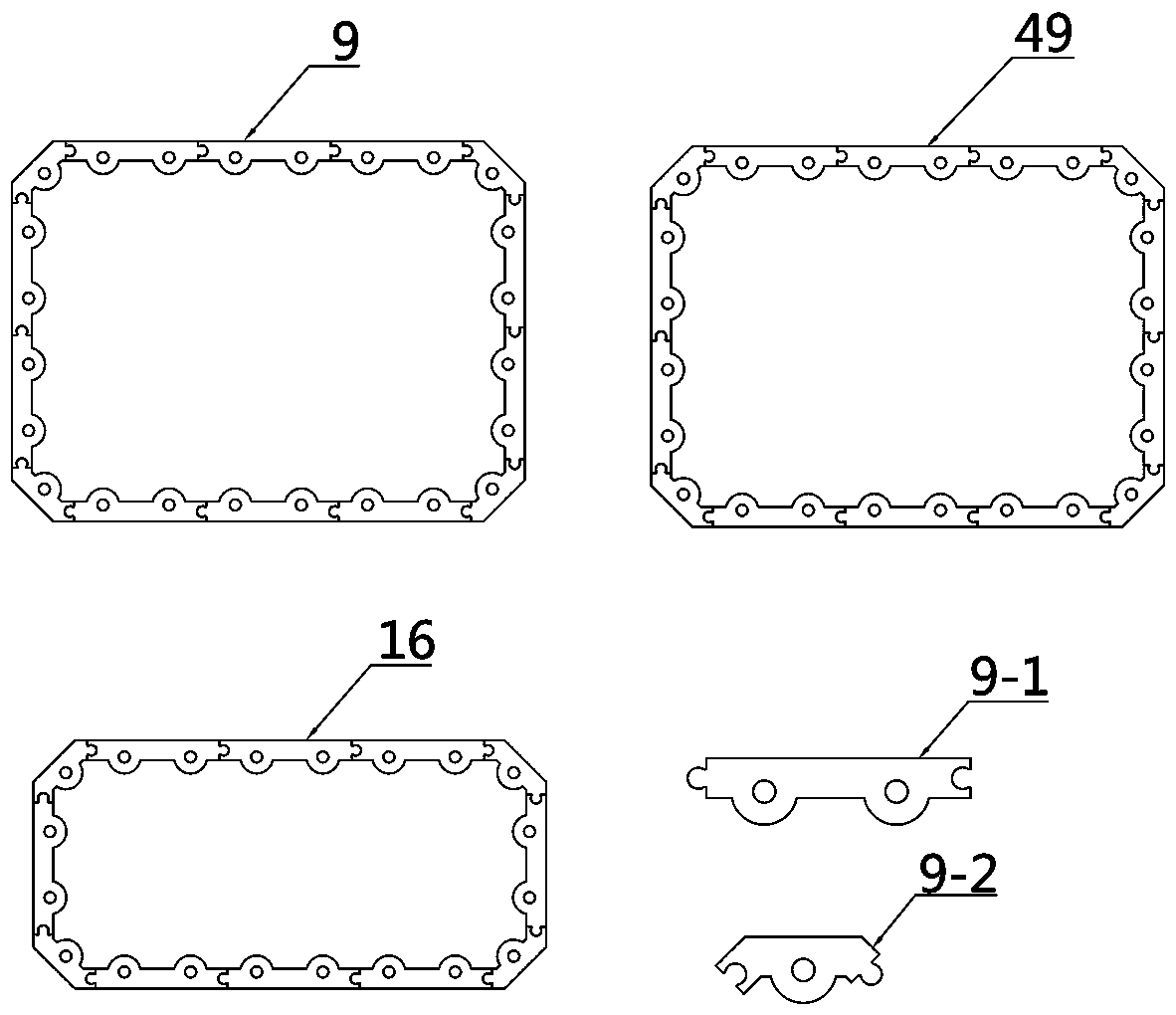

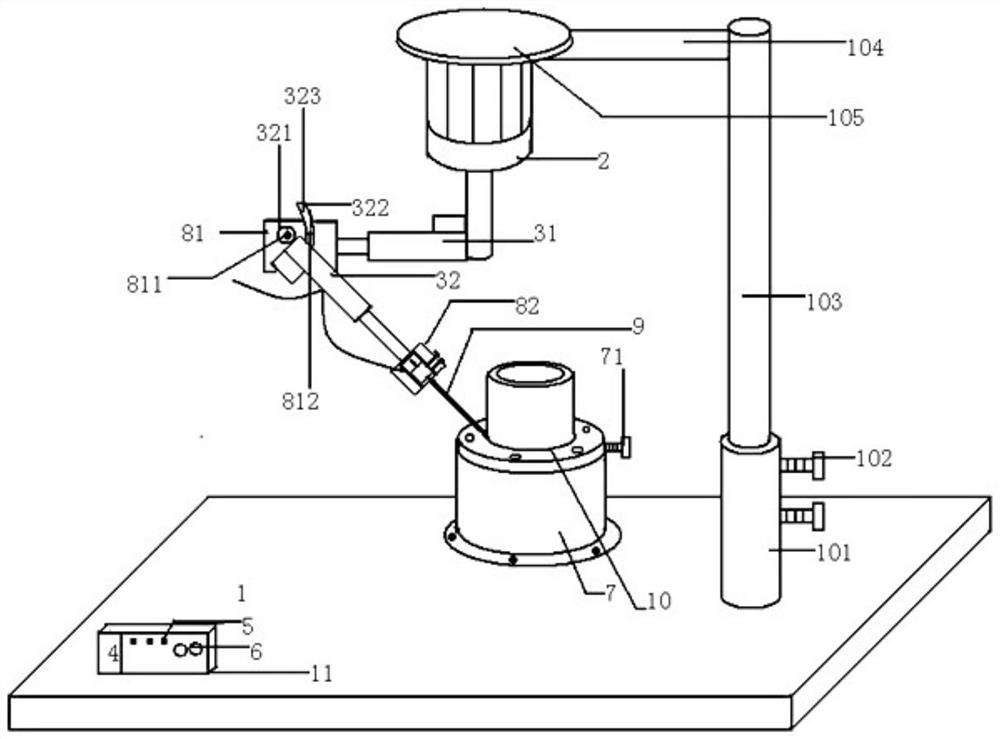

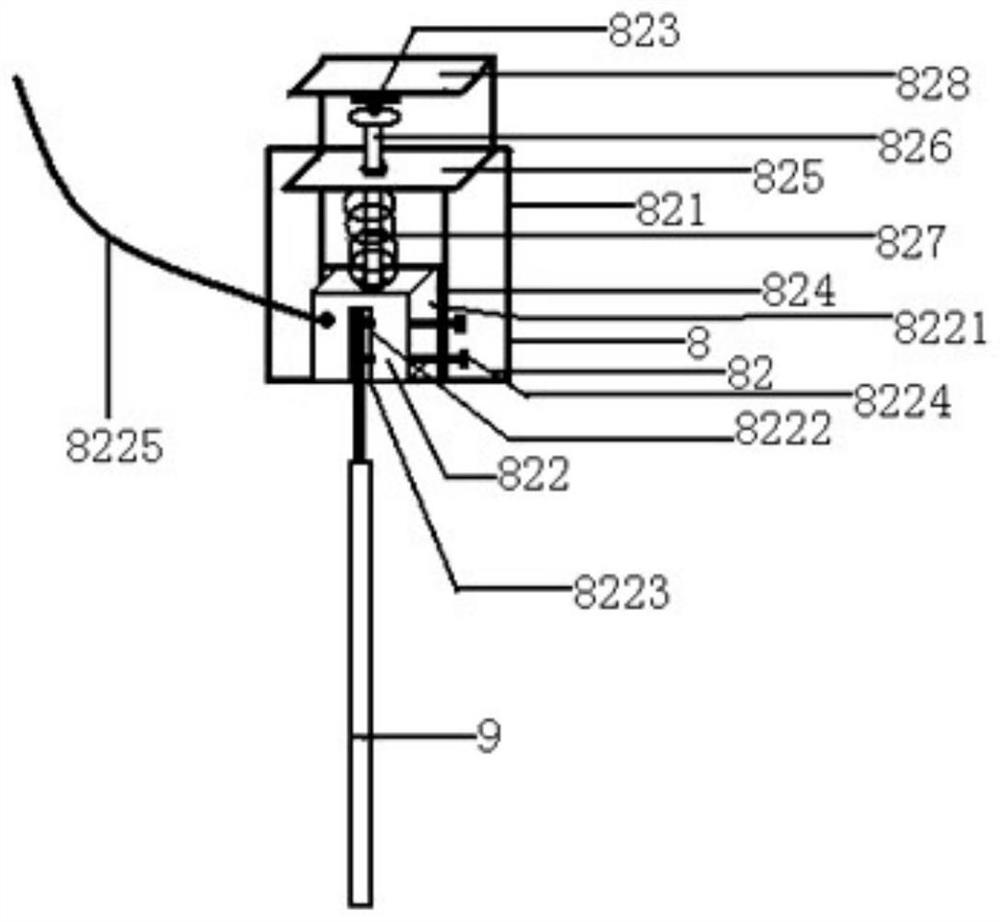

Rotary welding torch automatic welding robot

InactiveCN109834375AFunction increaseIncrease usageElectrode supporting devicesWelding accessoriesModular compositionEngineering

The invention discloses a rotary welding torch automatic welding robot. The robot is composed of three parts of an upright column component, a suspension arm beam component and a rotary welding torchsliding seat component. The upright column component is fixedly installed on the ground, the suspension arm component is installed on the upright column component, the rotary welding torch sliding seat component is installed on the suspension arm beam component, the suspension arm beam component can be manipulated by the upright column component to rotate around the upright column and lift and lower vertically, the rotary welding torch sliding seat component can be moved along the suspension arm beam, and a welding torch can be manipulated by the rotary welding gun sliding seat component to perform horizontal linear movement, vertical lifting and lowering movement, revolution rotation around the welding torch and rotation. The robot has the advantages that conditions of individualized customizing and modulation can be met, differential production can be achieved more efficiently and rapidly, and the welding demands of different shapes and sizes of all-direction welding are met.

Owner:徐州航天美利达自动焊接设备有限公司

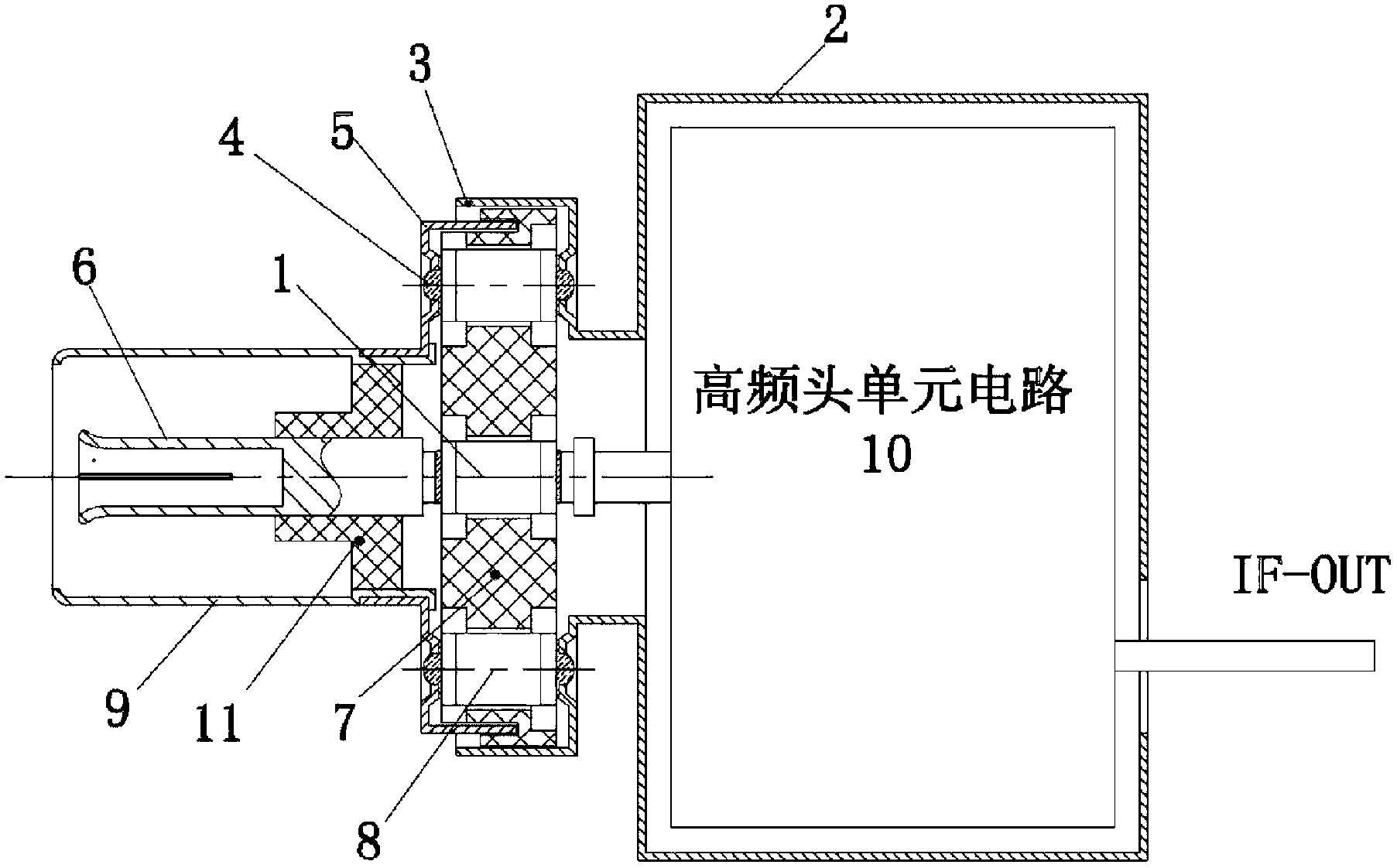

Television with antenna isolator

ActiveCN103237183AGuaranteed high frequency characteristicsHigh batch production efficiencyTelevision system detailsColor television detailsCapacitanceEngineering

The invention relates to a television which comprises a tuner assembly. The tuner assembly comprises a tuner unit circuit and the antenna isolator connected with a signal input end of the tuner unit circuit; the tuner unit circuit is arranged in an outer shielding case; and the antenna isolator comprises a pair of shielding cases, opening ends of the shielding cases are opposite to each other to form a shielding cavity, a shielding layer connector is arranged on the outer side of one of the shielding cases, and a rear port of the other shielding case is connected with an opening of the front end of the outer shielding case. The television has the advantages that the antenna isolator in the tuner assembly is provided with capacitors which are leadless capacitors or chip capacitors, the television is low in line loss, high-frequency characteristics of transmitted signals can be guaranteed, reflow soldering can be implemented beneficially, manual soldering is omitted, the television is suitable for batch production, and effects of high batch production efficiency, low cost and good consistency of products are realized.

Owner:JIANGSU HUAXING ELECTRONICS CO LTD

Circular tuyere welding device

InactiveCN113118680ADon't get splashedPrevent splashWelding/cutting auxillary devicesAuxillary welding devicesSlag (welding)Structural engineering

The invention discloses a circular tuyere welding device and belongs to the technical field of welding device. The circular tuyere welding device comprises a lower base, wherein a workbench is mounted at the top of the lower base; side fixing plates are fixedly connected to the two sides of the top of the workbench; telescopic columns are detachably mounted on one sides of the outer side walls of the side fixing plates; and limiting square pieces are detachably mounted at the tail ends of the telescopic columns. According to the circular tuyere welding device disclosed by the invention, a circular tuyere of an air conditioner can be intelligently and automatically welded, and a welding gun can be moved in the welding device in any direction of the X axis, the Y axis and the Z axis, so that the flexibility is high, manual welding is not needed, and manpower resources are saved; and the circular tuyere welding device disclosed by the invention is a closed welding device, observable glass windows are arranged on three faces, two sides are fixed, and the other side can slide in a double-track mode, so that observation during welding is facilitated, workers are protected from being splashed by welding slag, and the working safety is improved.

Owner:SHANGHAI YINDA AIR CONDITIONING ENTERPRISE

Plant core laser welding device

ActiveCN109365938AAvoid displacementHigh degree of automationSoldering auxillary devicesEngineeringLaser

The invention discloses a plant core laser welding device. The plant core laser welding device comprises a frame, a welding mechanism, a gripper mechanism, and a transmission mechanism for driving thegripper mechanism to move; the frame is provided with a platform for placing panels; the welding mechanism and the transmission mechanism are both connected with the frame; the welding mechanism comprises a linear slide table, and a welding machine head for welding core tubes on the panels; the linear slide table drives the welding machine head to move; and the gripper mechanism comprises a clamping part for clamping the core tubes. The core tubes can be automatically welded on the panels to prevent displacement thereof due to air currents in the brazing process, the conveying process or theprocess of paving on the panels, so that the brazing quality is improved; and the plant core laser welding device needs no manual welding, greatly improves the working efficiency, and reduces the labor cost.

Owner:远大可建科技有限公司

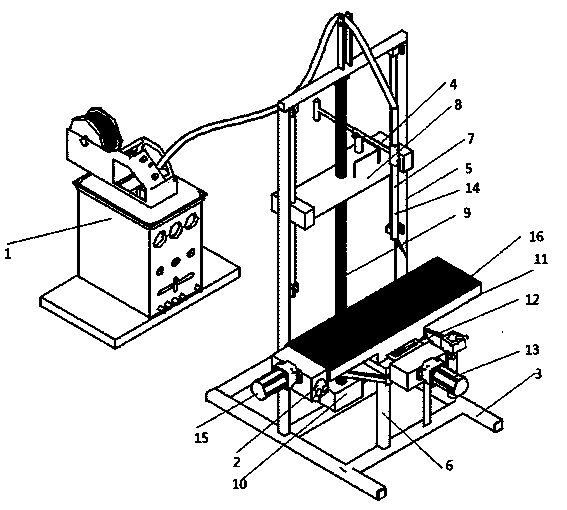

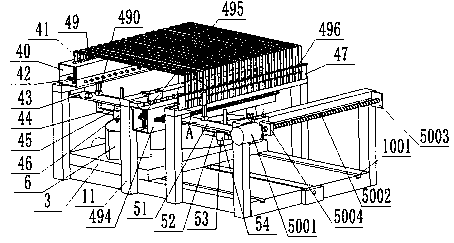

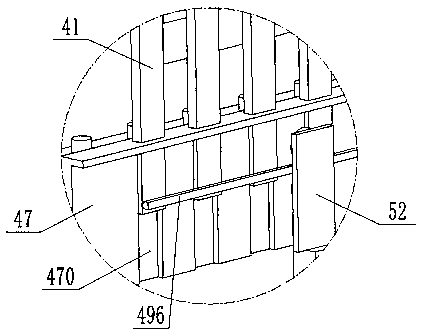

Full-automatic stereoscopic welding machine

InactiveCN104191120AEasy to operateImprove securityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a full-automatic stereoscopic welding machine which comprises a wire feeding welding machine body and a support device. The support device comprises a vertical seat, a welding gun adjusting rod, a vertical frame and a workbench support, a guide shaft is arranged in the vertical frame and is in sliding fit with a lifting body, a lifting screw rod is arranged in the lifting body in a spiral fit mode, and the lower end of the lifting screw rod is in transmission connection with a lifting motor. A workbench is vertically arranged at the upper end of the workbench support in a transverse sliding mode, a vertical screw rod is arranged in the workbench in a spiral fit mode, the outer portion of the vertical screw rod is in transmission connection with a vertical motor, and a welding gun is arranged on the welding gun adjusting rod. The full-automatic stereoscopic welding machine is convenient to operate, low in danger factor and suitable for beginners, and work efficiency is improved.

Owner:ANHUI LIFENG MACHINERY TOOL

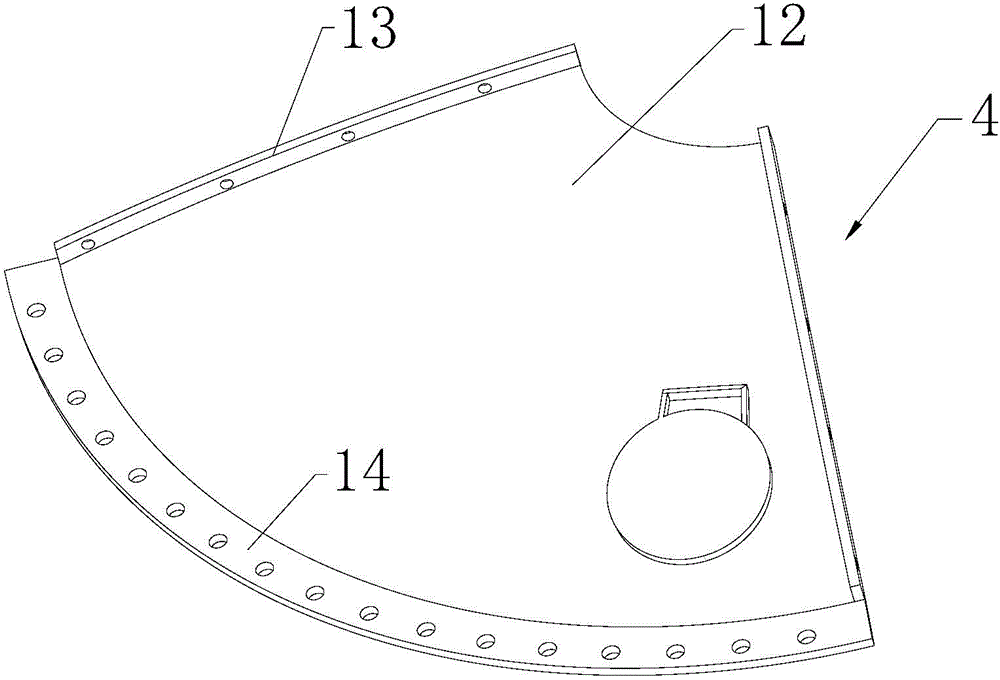

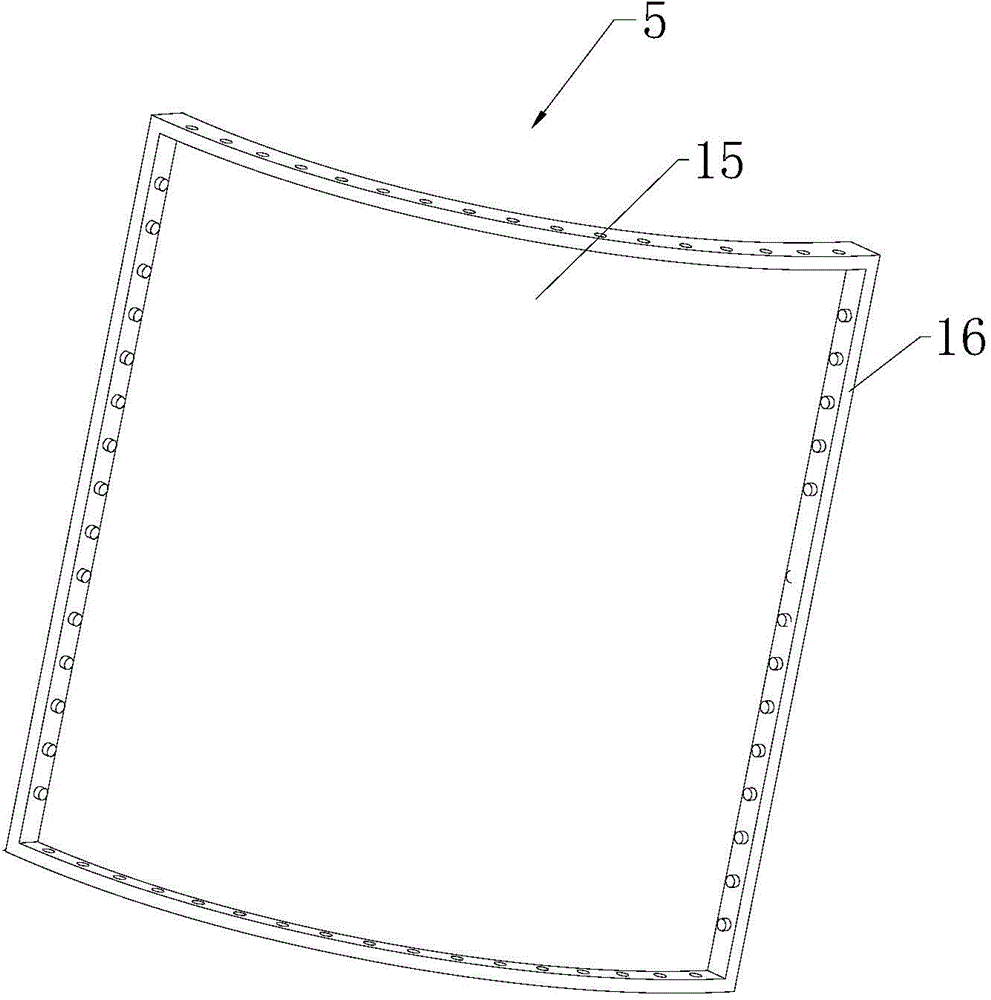

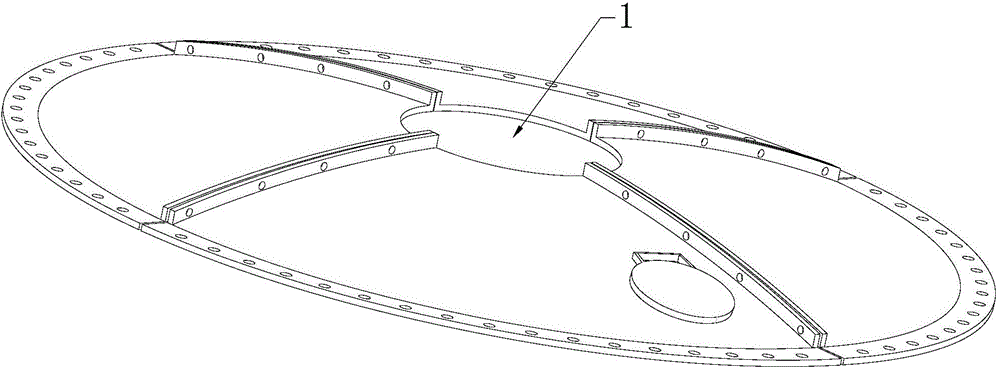

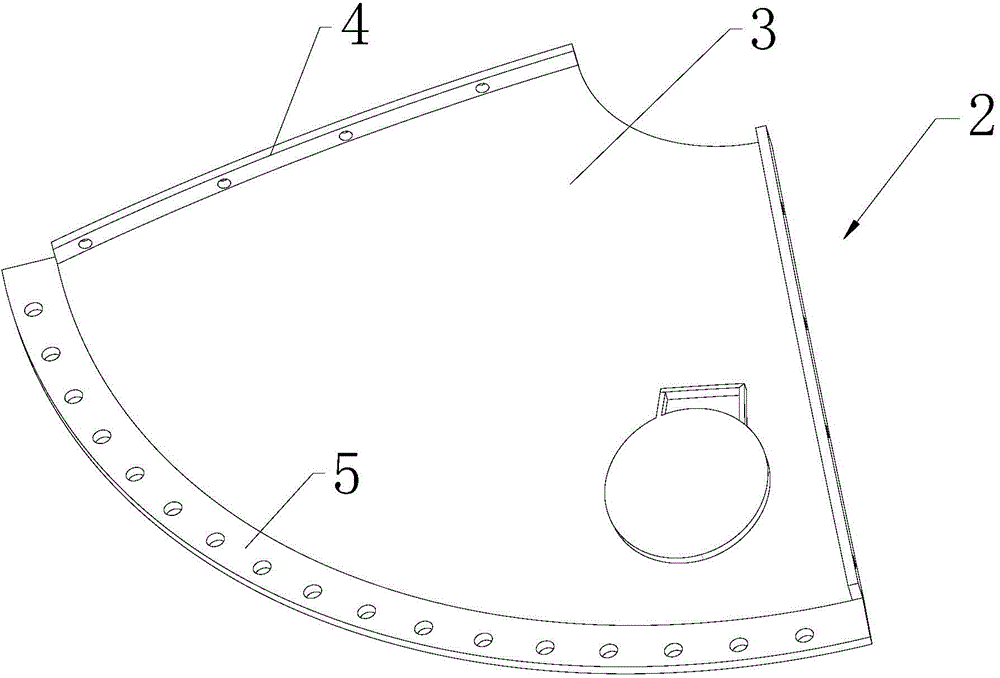

Lower cone body of cerement bin and manufacturing process of lower cone body

InactiveCN104370012ASame sizeNo manual welding requiredLarge containersCircular conePulp and paper industry

The invention provides a lower cone body of a cerement bin and a manufacturing method of the lower cone body. The lower cone body comprises a tail end tail cone body and at least one cone cylinder, wherein the cone cylinder and the tail end cone body are installed together through a fastening piece. The cone cylinder comprises a plurality of cone cylinder splicing modules, wherein the cone cylinder splicing modules are assembled to form the cone cylinder. Each cone cylinder splicing module comprises a cone cylinder splicing module body, wherein cone cylinder strip-shaped flanges are arranged on the left side and the right side of the cone cylinder splicing module body respectively, and the cone cylinder strip-shaped flanges are integrally formed through a hydraulic machine. The cone cylinder strip-shaped flanges of every two adjacent cone cylinder splicing modules are installed together through fastening pieces. Cone cylinder arc-shaped flanges are welded to the upper end and the lower end of each cone cylinder splicing module body respectively. Each cone cylinder arc-shaped flange is fixedly connected with the upper end of a middle cylinder of the cerement bin. By means of the lower cone body and the manufacturing method, the production cycle is greatly shortened, cost is greatly reduced, all bin bodies are the same in size, the lower cone bodies can be produced in batches, standardization is achieved, transportation is convenient, and the lower cone body can be rapidly assembled on site.

Owner:潍坊金河机械有限公司

A precision welding equipment for pipe flanges

ActiveCN111872513BReliable weldingLow operating skill requirementsElectrode supporting devicesWelding accessoriesPower switchingElectric machinery

A pipe flange precision welding equipment, including welding machine body, base plate, motor deceleration mechanism, electric telescopic rod, switching power supply, power switch, speed control switch, fixed sleeve; also has welding rod fixing detection mechanism; base plate, motor deceleration mechanism , Two sets of electric telescopic rods and fixed sleeves are installed on the bottom plate, switching power supply, three power switches, and two sets of speed control switches are installed in the component box, and are electrically connected with the motor deceleration mechanism and electric telescopic rods. The welding machine body It is connected with the welding rod fixing detector and the chassis through wires. The present invention has the advantages of small size, simple and compact structure, and low cost, and can be used conveniently in any required place. It can be used after simple adjustment during use, and does not require high operating skills of operators, and does not require manual welding, which reduces the It is an automatic electric welding machine that is less labor-intensive for the operator and brings convenience to the operator. Based on the above, the present invention has good application prospects.

Owner:NINGXIA DEXING & HENGTONG PIPE IND

Automobile tail pipe welding device

PendingCN112338436AAvoid shakingNo manual welding requiredWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryStructural engineering

The invention discloses an automobile tail pipe welding device. The automobile tail pipe welding device comprises a supporting table, a first box body and a second box body, wherein the supporting table is fixedly connected with the first box body; the first box body is arranged on the left side of the second box body; a fixing frame is arranged in the supporting table; a first sliding groove is formed in the right side of the first box body; a second sliding groove is formed behind the first sliding groove; and a first clamping groove is formed above the second sliding groove. By designing anabutting rod, an L-shaped abutting rod, a first L-shaped supporting arm and a second L-shaped supporting arm, after a semi-finished product is inserted into the first L-shaped supporting arm and thesecond L-shaped supporting arm, the L-shaped abutting rod is contracted backwards through a hydraulic rod, the L-shaped abutting rod is extruded with the front end of the semi-finished product, the semi-finished product is fixed, and shaking is avoided; and the first L-shaped supporting arm and the L-shaped abutting rod are extruded rightwards at the same time through a first drive motor, and thefree ends of the two sides of the semi-finished product are engaged with each other. By designing a supporting arm, a threaded handle and a clamping plate, the automobile tail pipe welding device canbe externally connected with an electric welding gun, and manual welding is not needed.

Owner:NINGGUO LONGSHI METAL PROD CO LTD

Butt-welding robot

ActiveCN111515595ARealize automatic weldingRealize batch weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld seam

The invention discloses a butt-welding robot. The butt-welding robot comprises a platform frame, a movable welding table, a first linear driving device, a memory control device and an execution device, wherein the movable welding table is movably installed on the working face below the platform frame through the first linear driving device; the memory control device comprises a vertical memory mechanism; the vertical memory mechanism comprises a first box, a U-shaped connecting rod, a first floating clamping assembly, a first flexible guide rail, a guide rail base, a first welding head, a first welding beam, a first portal frame and a first sliding block; and the execution device comprises a second portal frame, a first welding beam, a second welding head, a second linear driving device and a first wheel. According to the butt-welding robot, the position change of a welding seam of a to-be-welded part is recorded through the memory control device, then the execution device achieves automatic welding of the welding seam of the to-be-welded part according to the position recorded by the memory control device, the welding quality is guaranteed, batch welding of the to-be-welded part is achieved, and the production efficiency is high.

Owner:湖南翰坤实业有限公司

Box beam welding equipment and welding method

InactiveCN108817764AQuality improvementReduce harmWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPressure measurement

The invention relates to the technical field of welding and particularly relates to box beam welding equipment. The box beam welding equipment comprises an X-axis moving device, a Y-axis moving device, a Z-axis moving device, a mounting frame and a welding device, wherein the X-axis moving device, the Y-axis moving device, the Z-axis moving device, the mounting frame and the welding device are connected sequentially; the welding device is installed at the mounting frame; a baffle component is installed at the mounting frame; the welding device is arranged at one side of the baffle component; afirst pressure measuring component and a second pressure measuring component are installed at the mounting frame; the Y-axis moving device is provided with a welding wire conveying device; the box beam welding equipment further comprises a control device; the control device is correspondingly electrically connected with the X-axis moving device, the Y-axis moving device, the Z-axis moving device,the welding device and the welding wire conveying device; and the first pressure measuring component is electrically connected with the second pressure measuring component. Besides, the invention further provides a box beam welding method, the welding efficiency and quality is improved, and injuries of a welding worker are reduced.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD +1

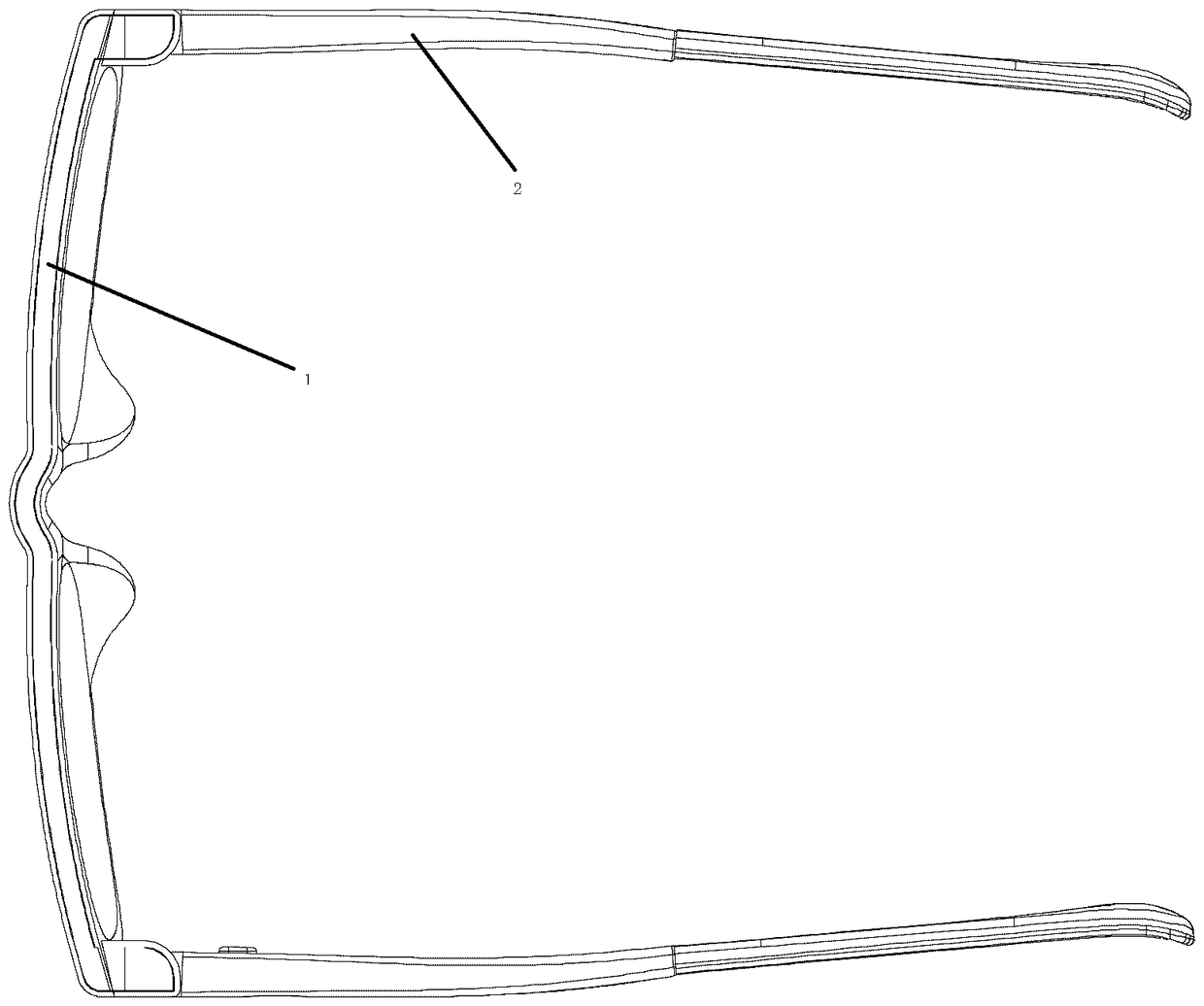

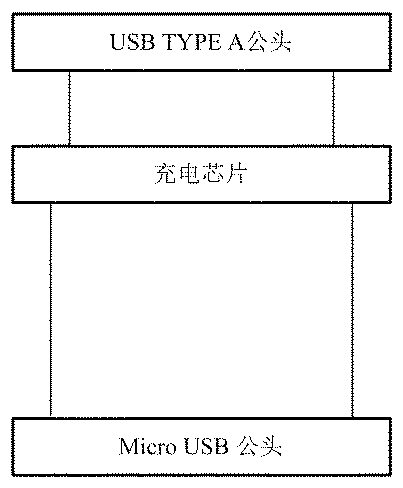

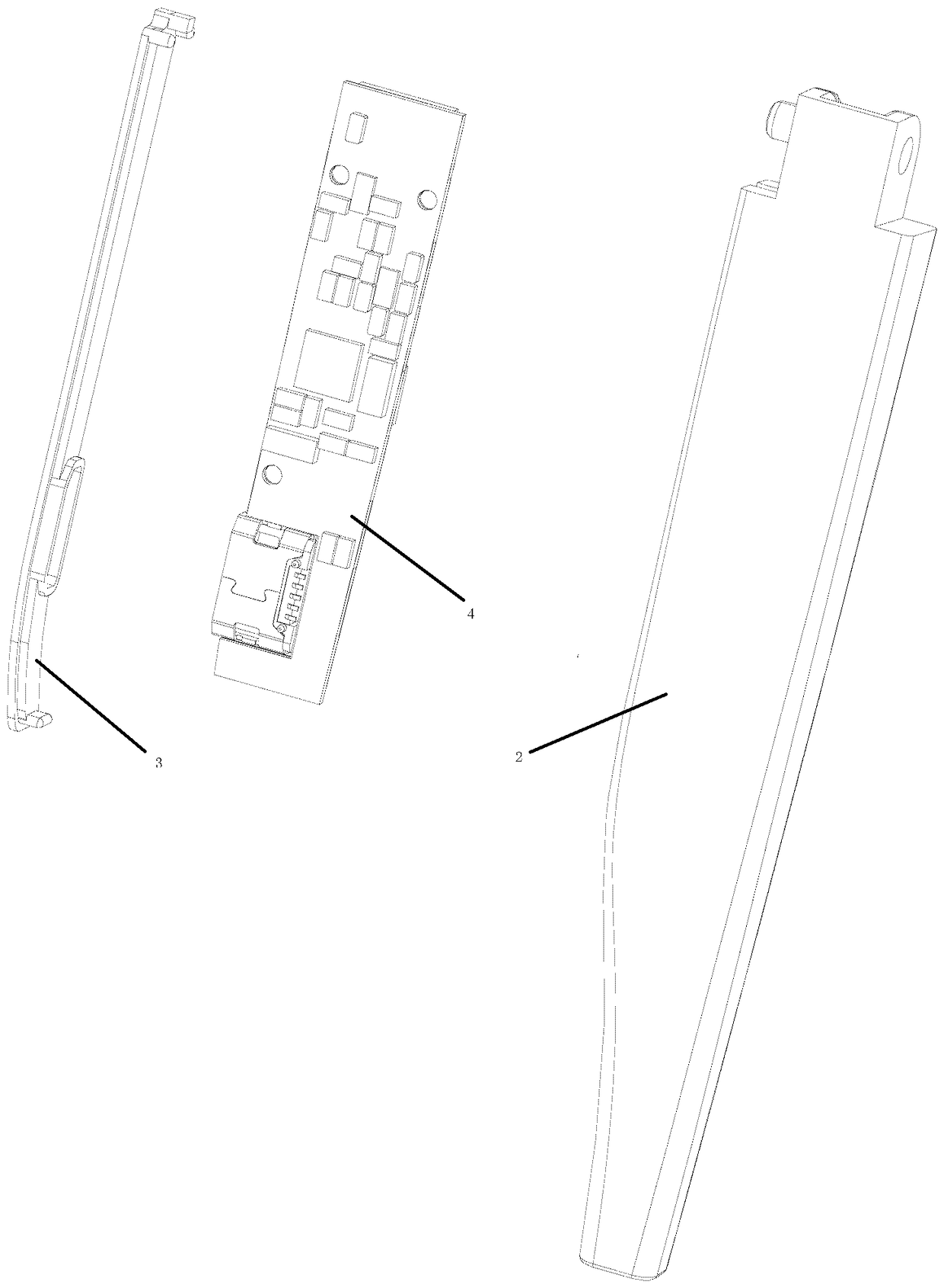

Spectacle frame with low cost, intelligence, myopia prevention and treatment, and sitting posture correction

InactiveCN109283703AExtend standby timeExtended use timeNon-optical adjunctsPower flowCurrent consumption

The invention discloses a spectacle frame with low cost, intelligence, myopia prevention and treatment, and sitting posture correction. In view of the problems of high price, difficult installation and short using time by charging once in a current market and related patents, innovation is made, and so, the material cost of a product is minimized, the volume is minimized, the assembly efficiency and the yield are improved, the cost is reduced, the current consumption is reduced, the using time by charging once becomes long, the purchase and use experience of a user is improved.

Owner:邵建军

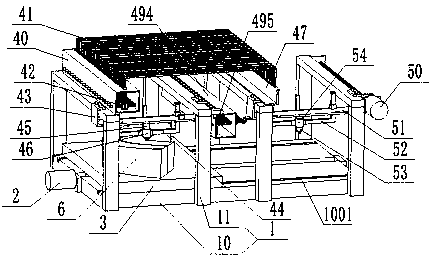

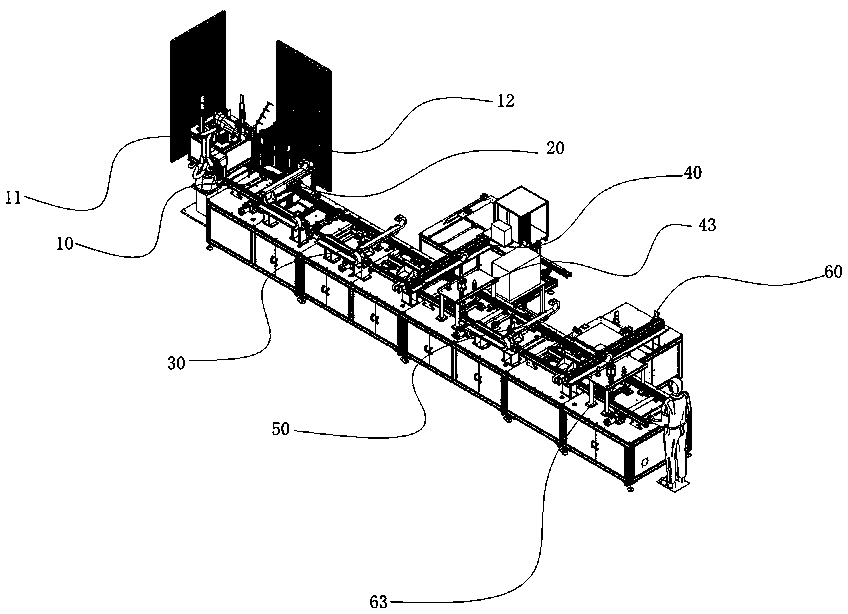

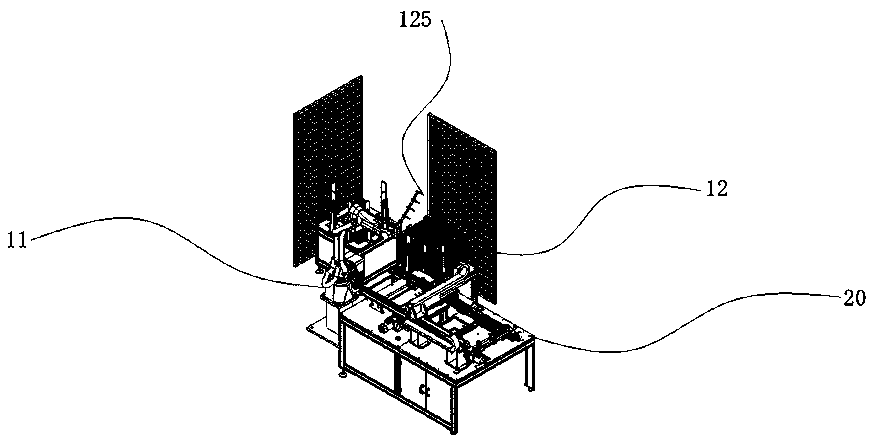

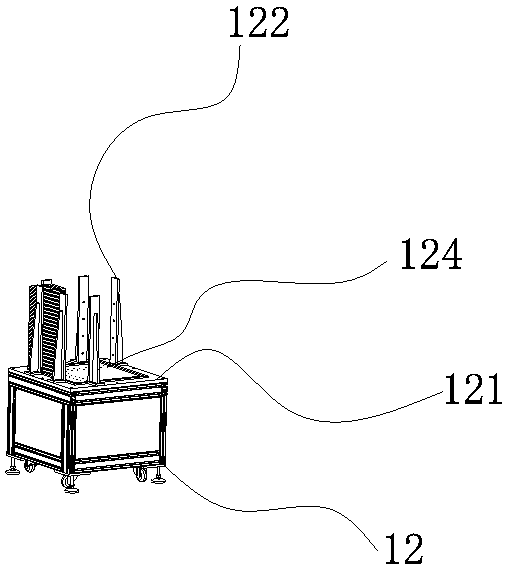

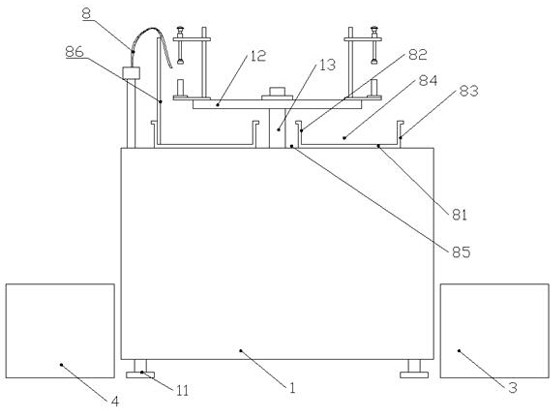

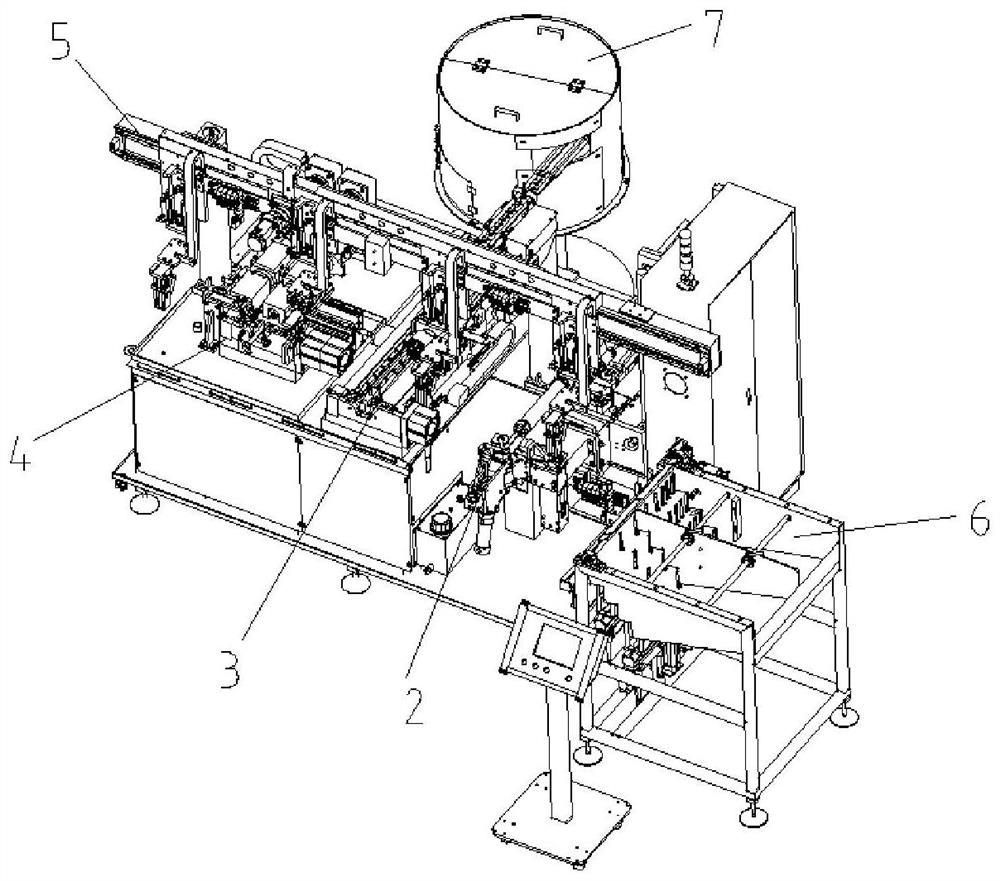

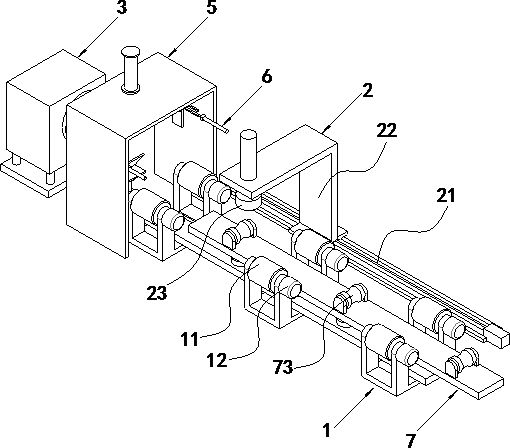

Full-automatic intelligent production system for LED light box

InactiveCN110181270ANo human intervention requiredNo manual welding requiredLiquid surface applicatorsAssembly machinesBackplaneMagnet

The invention aims at disclosing a full-automatic intelligent production system for an LED light box. The full-automatic intelligent production system comprises an automatic feeding unit, a magnet mounting unit, a first automatic dispensing unit, a light guide plate mounting unit, a second automatic dispensing unit and a backboard mounting unit which are sequentially arranged; the automatic feeding unit, the magnet mounting unit, the first automatic dispensing unit, the light guide plate mounting unit, the second automatic dispensing unit and the backboard mounting unit are fixedly connected with each other by a transfer rail; and an output end of the backboard mounting unit is provided with a manual discharging unit. Compared with the prior art, the automatic production of the LED light box can be completed through the automatic feeding unit, the magnet mounting unit, the first automatic dispensing unit, the light guide plate mounting unit, the second automatic dispensing unit and thebackboard mounting unit without manual intervention or manual welding, so that production efficiency and consistency are high, defect rate is effectively reduced, product quality is guaranteed, product safety is improved, labor cost is reduced, and the object of the automatic intelligent production system is achieved.

Owner:SHANGHAI EDGE LIGHT IND

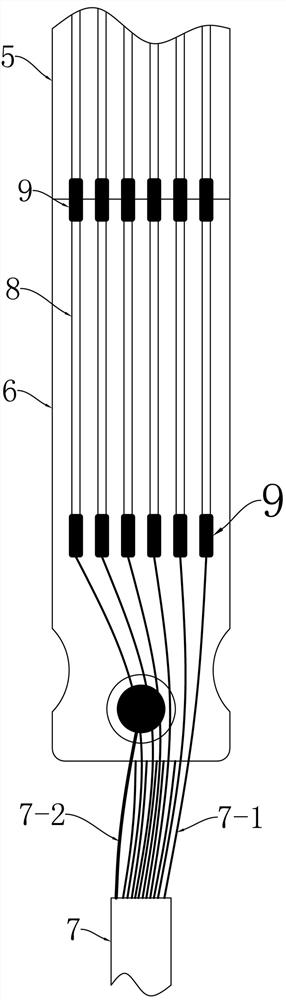

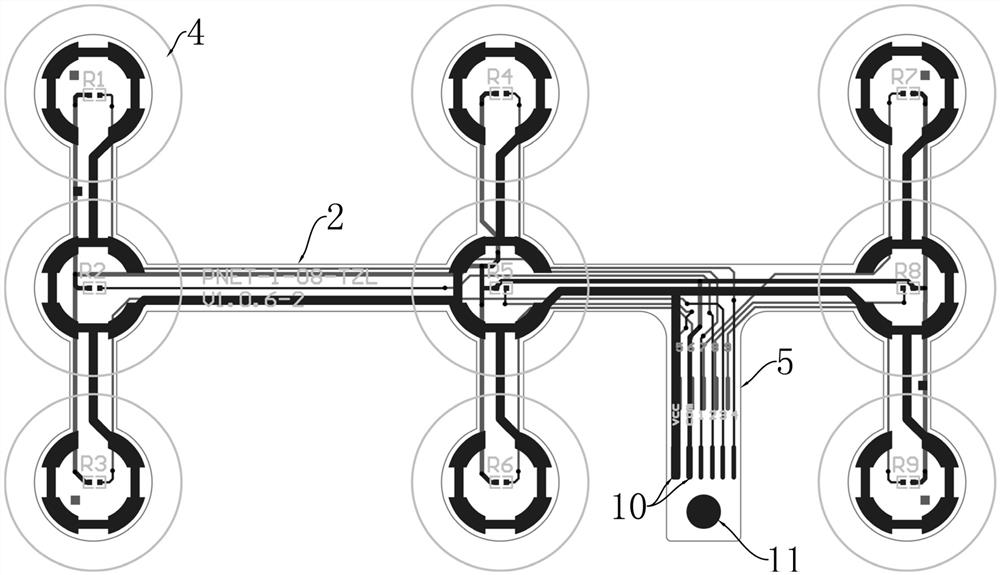

Flexible circuit board patch cord structure and electrode patch for treating tumors in electric field

PendingCN114603229AWeld firmlyConvenient welding operationPrinted circuit assemblingExternal electrodesFlexible circuitsStructural engineering

The invention relates to a flexible circuit board patch cord structure and an electrode patch for treating tumors in an electric field. The patch cord structure comprises a flexible circuit board, a wiring board is arranged on the flexible circuit board, and line contacts at the end heads of a plurality of circuit wires are gathered on the front and back surfaces of the wiring board; the adapter plate is a rectangular strip-shaped flexible adapter plate, two ends of the adapter plate are respectively provided with a plurality of adapter wires, and two ends of each adapter wire are respectively provided with an adapter contact piece; after the flexible adapter plate is folded, the rotary contact pieces at the edges of the two end parts are respectively welded with the line contact pieces on the front and back surfaces of the wiring board, and the rotary contact piece close to the middle part is welded with a plurality of leads in the transmission cable. The electrode patch comprises the flexible circuit board patch cord structure.

Owner:HEBEI PUNI MEDICAL TECH CO LTD

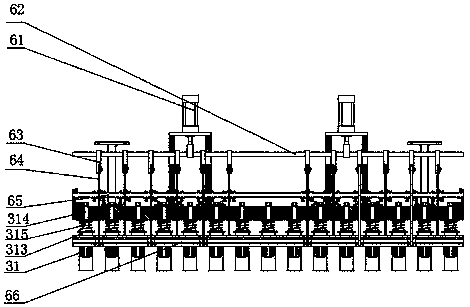

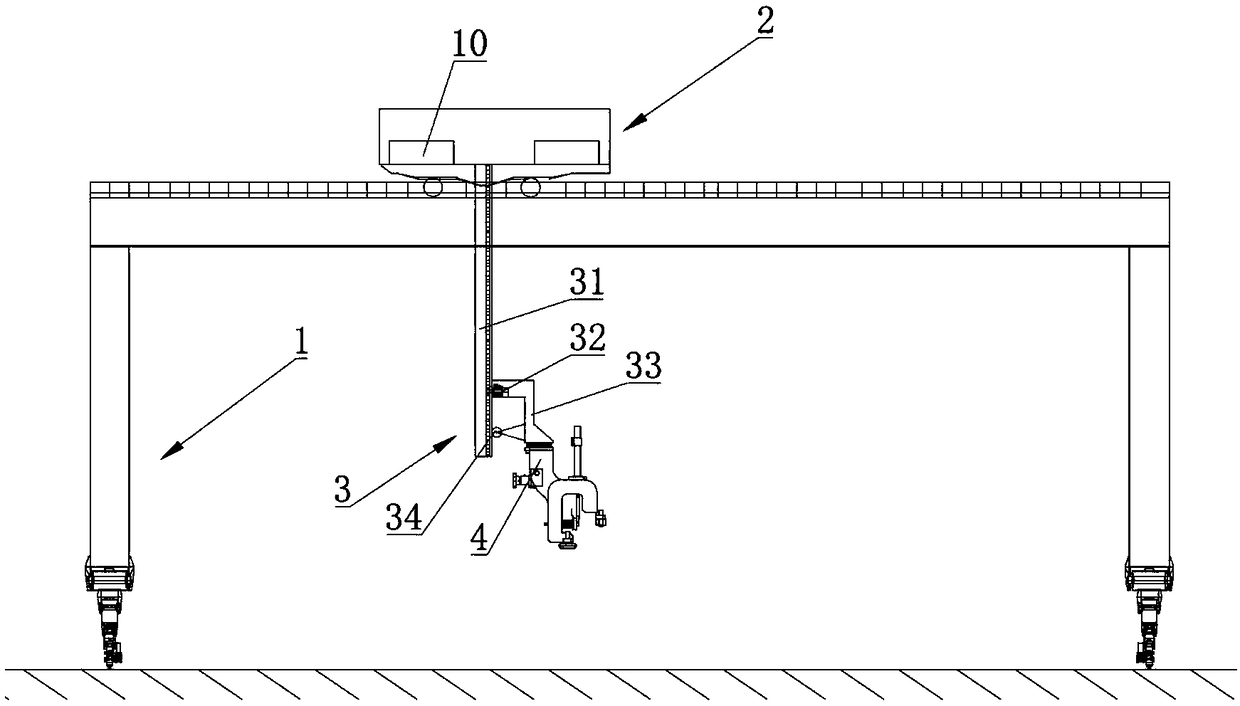

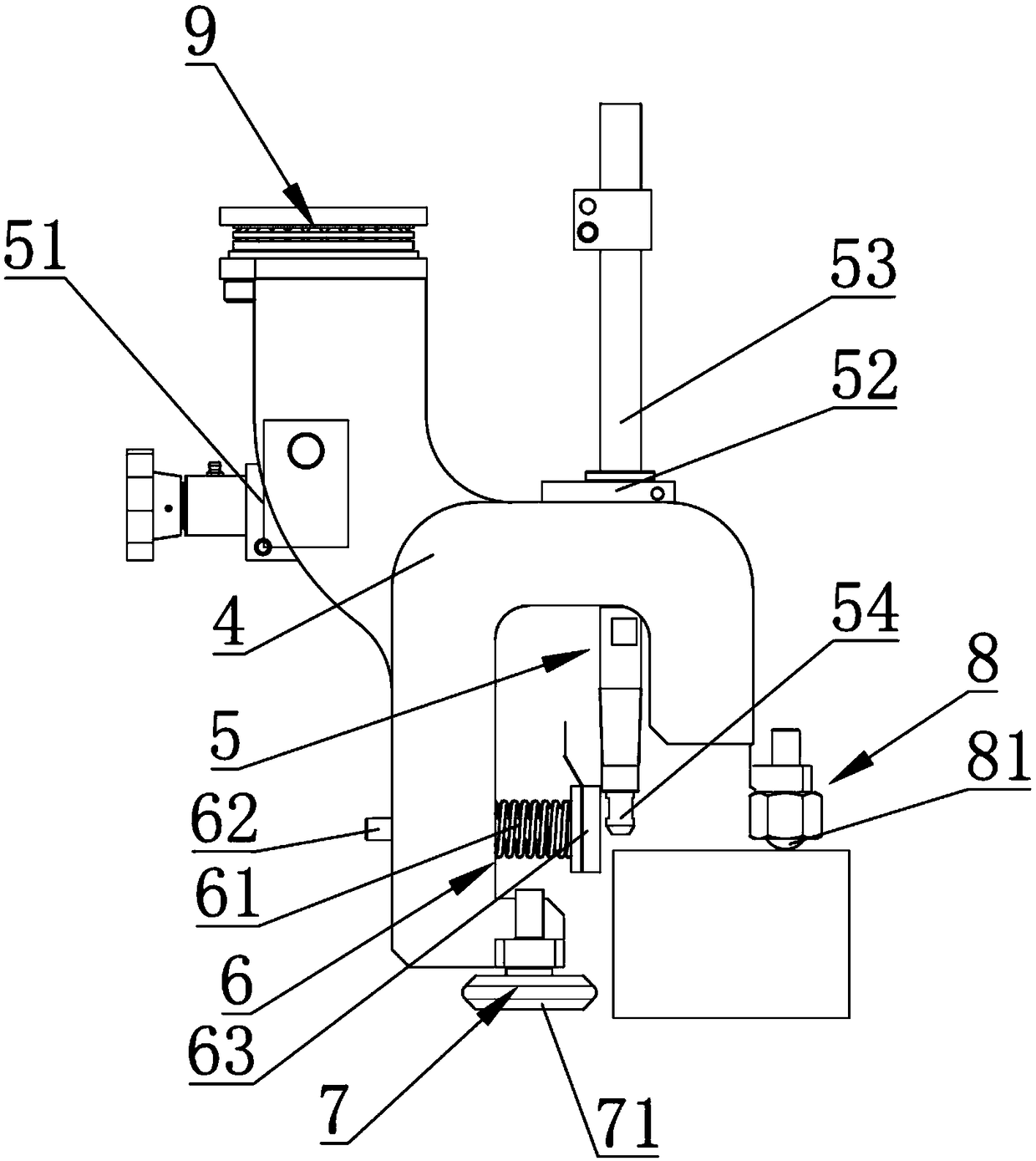

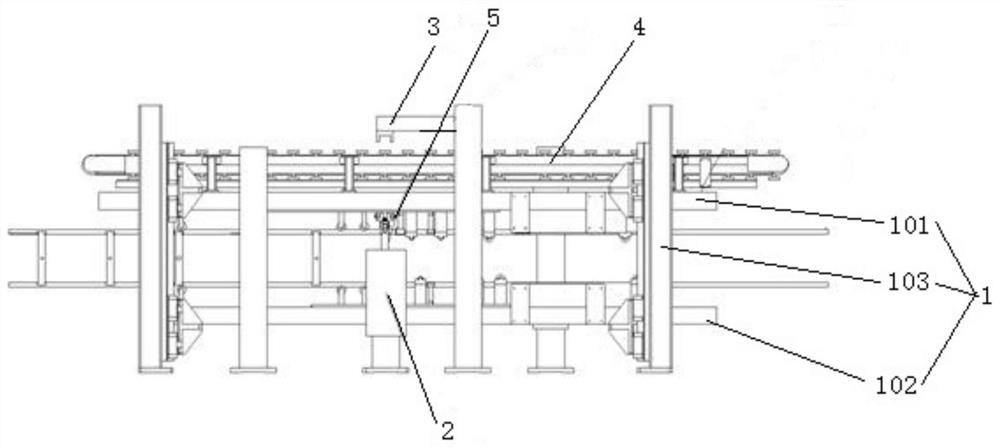

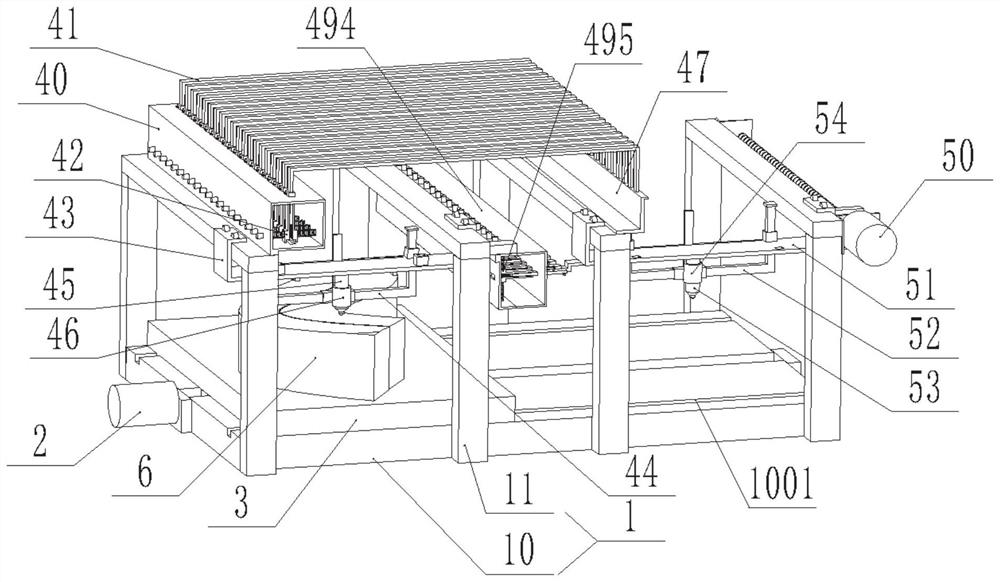

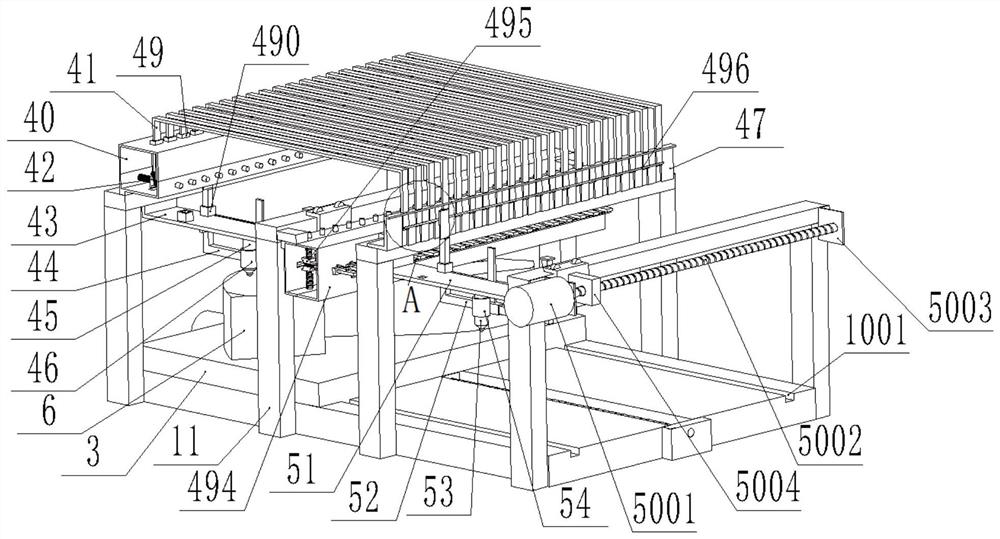

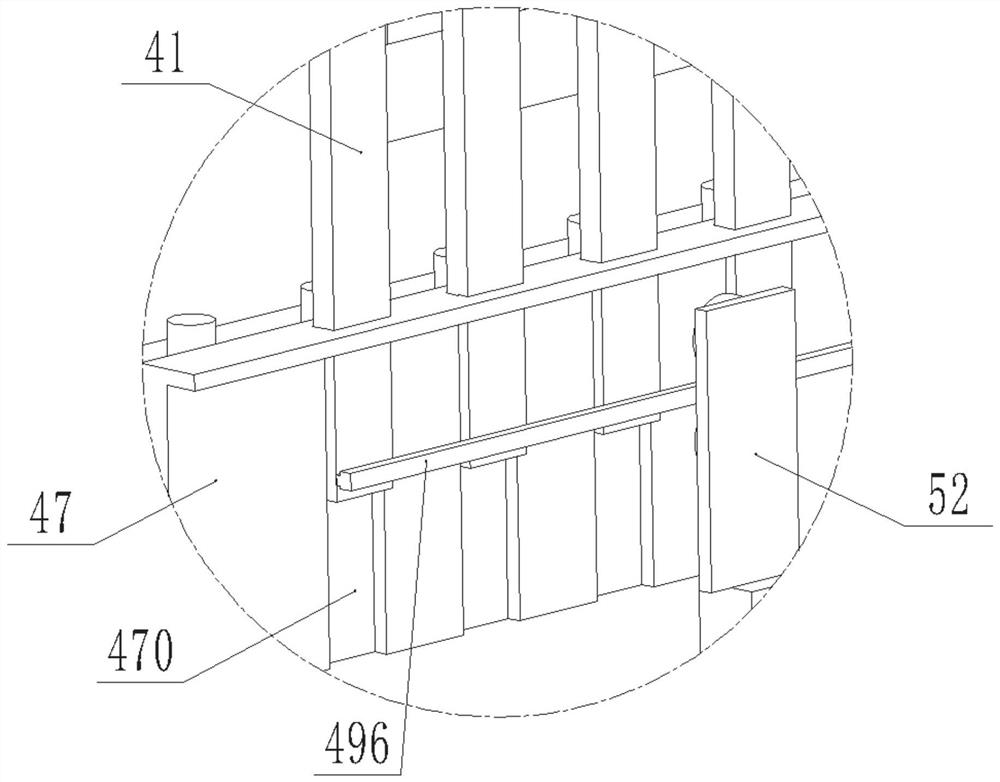

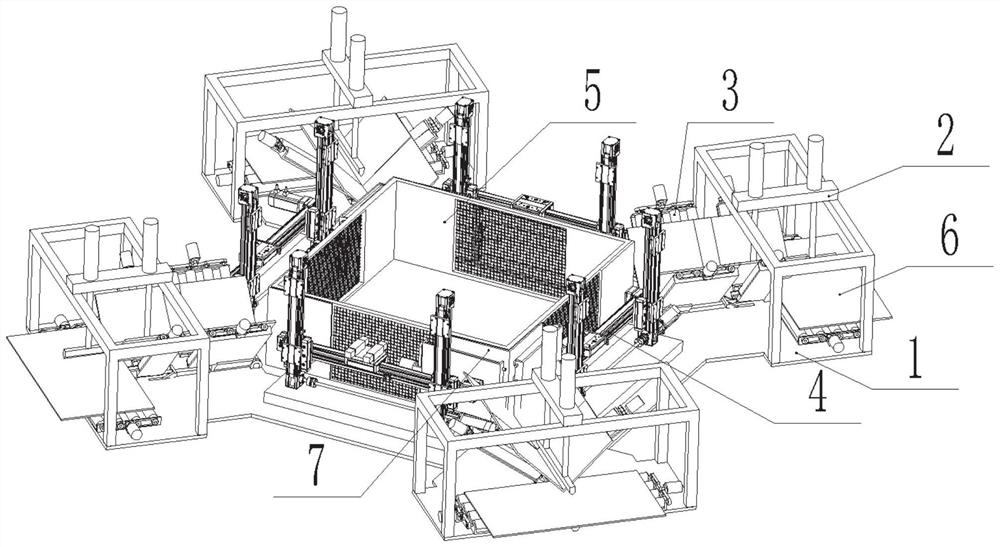

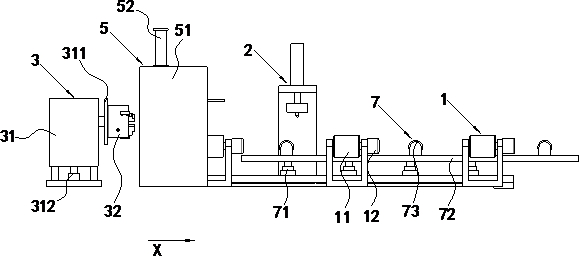

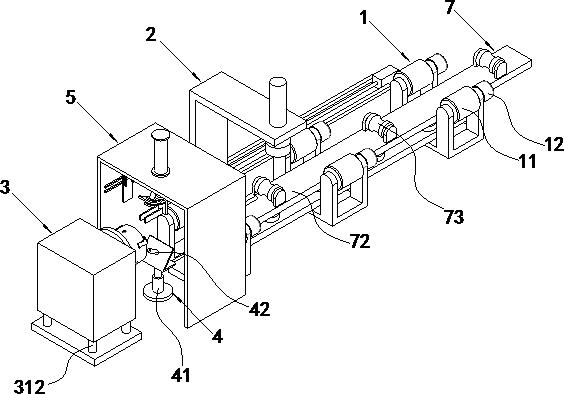

A main keel welding equipment and welding method

ActiveCN110153578BImprove the efficiency of welding operationsEase of large-scale industrializationWelding apparatusKeelIndustrial engineering

The invention discloses a main keel welding equipment and a welding method to improve operation efficiency and realize large-scale production. The main keel welding equipment includes a frame and a welding device, and the welding device is arranged opposite to the frame; when in use, the main keels to be welded are located in the frame and arranged vertically.

Owner:江苏景枫投资控股集团有限公司

Positioning device used for automobile lock rod welding machining

ActiveCN112171157AReduce labor intensityImprove securityWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryHydraulic ram

The invention relates to the technical field of automobile accessory machining devices, in particular to a positioning device used for automobile lock rod welding machining. The positioning device comprises a positioning seat and a welding seat, the positioning seat comprises a horizontal workbench, a vertical fixed table, a vertical movable table, a middle supporting table and a lock ring positioning table, transmission mechanisms are mounted on the vertical fixed table and the vertical movable table correspondingly, the transmission mechanisms comprise driving motors, driving rotating wheelsand driven rotating wheels, and the welding seat comprises a second hydraulic oil cylinder and a welding branch gun. According to the positioning device used for automobile lock rod welding machining, a lock rod and a lock head can synchronously rotate along with the driving rotating wheel and the driven rotating wheel and cooperate with repeated descending and ascending of the second hydraulic oil cylinder, 360-degree complete welding can be carried out on the joint of the lock head and the lock rod and the joint of a lock ring and the lock rod in a circle, the welding quality and welding precision are ensured, manual welding is not needed, the labor intensity is reduced, the safety of the operation is improved, after welding is completed, the welded locking rod can be rapidly and effortlessly cleared up and arranged conveniently, the working efficiency is greatly improved, the labor intensity is reduced, and the production progress is accelerated.

Owner:合肥同宏机电科技有限公司

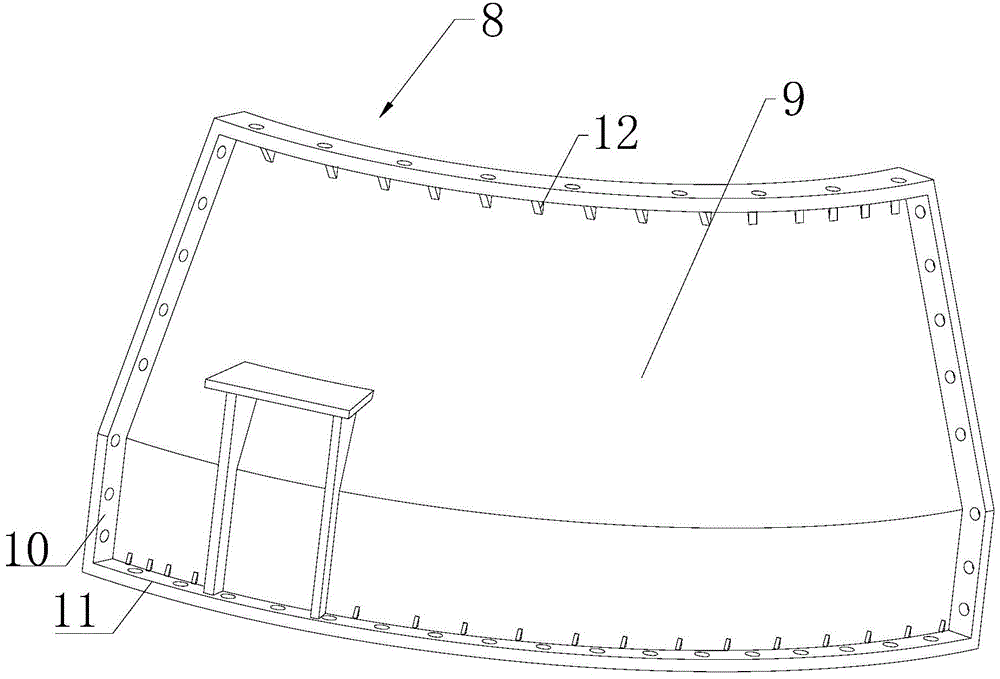

Upper cone body of cerement bin and manufacturing process of upper cone body

The invention provides an upper cone body of a cerement bin and a manufacturing process of the upper cone body. The upper cone body comprises a plurality of upper cone body splicing modules which are the same in size. The upper cone body splicing modules are assembled into the upper cone body. Each upper cone body splicing module comprises an upper cone body splicing module body, wherein upper cone body strip-shaped flanges are arranged on the left side and the right side of the upper cone body splicing module body respectively, and the upper cone body strip-shaped flanges are integrally formed through a hydraulic machine. The upper cone body strip-shaped flanges of every two adjacent upper cone body splicing modules are installed together through fastening pieces. An upper cone body arc-shaped flange is welded to the lower end of each upper cone body splicing module body. Each upper cone body arc-shaped flange is fixedly connected with the upper end of a middle cylinder. By means of the upper cone body and the manufacturing process, the production cycle is greatly shortened, cost is greatly reduced, all bin bodies are the same in size, the upper cone bodies can be produced in batches, standardization is achieved, transportation is convenient, and the upper cone body can be rapidly assembled on site.

Owner:潍坊金河机械有限公司

Intelligent butt-welding machine

ActiveCN111716054ARealize automatic weldingRealize batch weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld seam

The invention discloses an intelligent butt-welding machine. The intelligent butt-welding machine comprises a platform frame, a movable welding table, a first linear driving device, a memory control device and an execution device, wherein the movable welding table is movably installed on a working surface below the platform frame through the first linear driving device; the memory control device comprises a vertical memory mechanism; the vertical memory mechanism comprises a first box body, a U-shaped connecting rod, a first floating clamping assembly, a first flexible guide rail, a guide railseat, a first welding head, a first welding beam, a first portal frame and a first sliding block; and the execution device comprises a second portal frame, a first welding beam, a second welding head, a second linear driving device and a first roller. According to the intelligent butt-welding machine, the position change of a welding seam of a to-be-welded piece is recorded through the memory control device, then by the execution device, automatic welding of the welding seam of the to-be-welded piece is realized according to the position recorded by the memory control device, so that the welding quality is guaranteed, batch welding of to-be-welded pieces is realized, and the production efficiency is high.

Owner:湖南翰坤实业有限公司

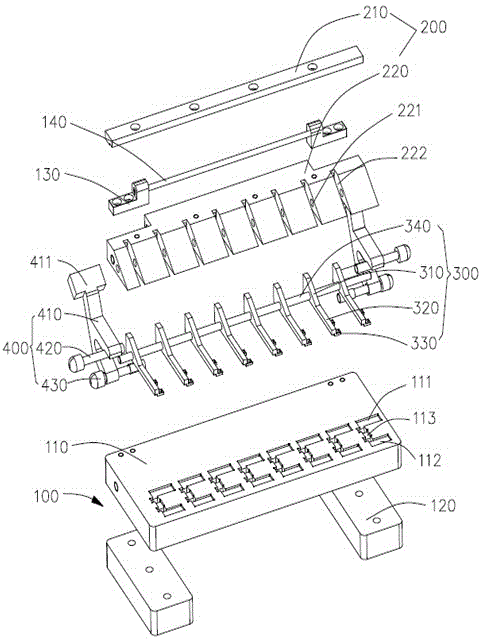

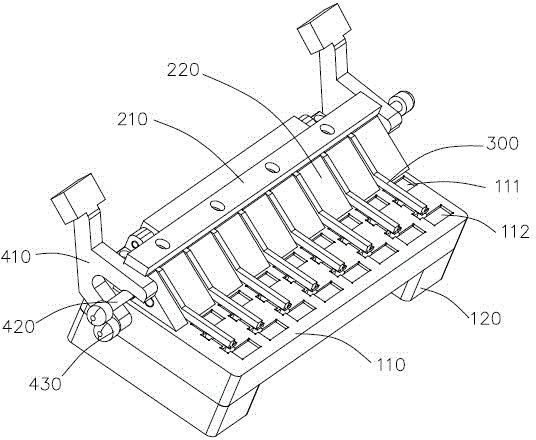

Automatic column skeleton production equipment

ActiveCN111702487BRealize automatic weldingNo manual welding requiredOther manufacturing equipments/toolsPunchingStructural engineering

The invention discloses an automatic column skeleton production equipment, comprising: a working platform; a stamping and bending mechanism, the stamping and bending mechanism is installed on the working platform, and is used for bending steel plates, and bends the steel plates into 90 °; floating conveying mechanism, the floating conveying mechanism is installed on the working platform, the said floating conveying mechanism conveys the flat bent steel plate to the right angle of the column frame, and then rotates the bent steel plate into a vertical state, so that the bent steel plate The bent steel plate wraps the right angle of the column skeleton; the welding mechanism, the welding mechanism is installed on the working platform, after the bent steel plate wraps the right angle of the column skeleton, the welding mechanism will bend the steel plate and the column skeleton welded together. The invention realizes the automatic welding of the column skeleton and the steel plate, does not need manual hand-held welding head welding, has high production efficiency, and is beneficial to realizing batch production.

Owner:湖南翰坤实业有限公司

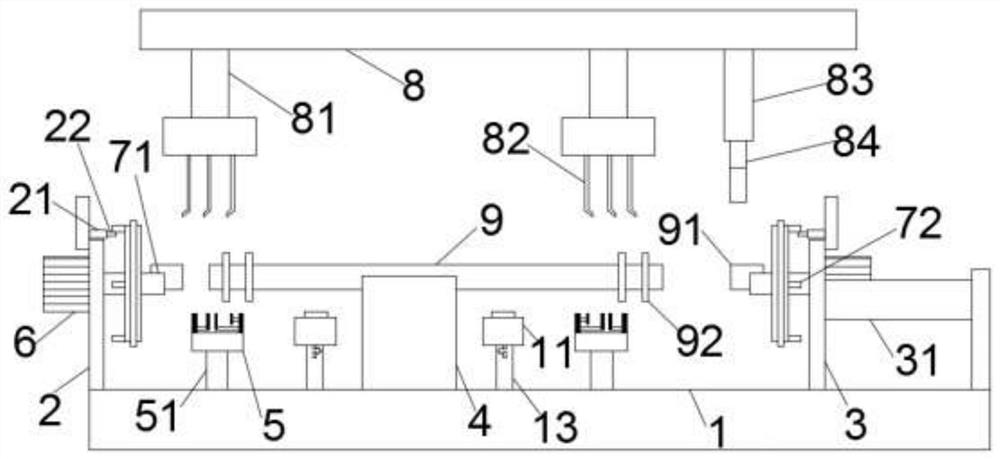

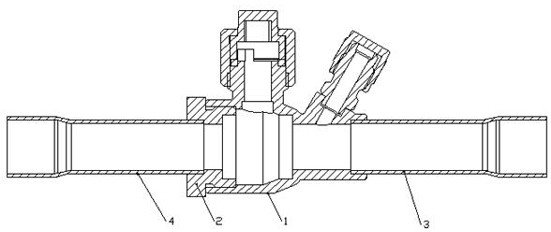

Welding system for ball valve of refrigerating system

PendingCN112828493ARealize automatic weldingNo manual welding requiredWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryEngineering

The invention relates to a welding system for a ball valve of a refrigerating system. The welding system comprises a welding base, a welding turntable is mounted on the upper end surface of the welding base, the welding turntable is driven to rotate by a welding motor mounted on the welding base, a plurality of workpiece placing seats are distributed on the upper end surface of the welding turntable in parallel in the circumferential direction of the welding turntable, and a feeding area, a preheating area, a welding area, a cooling area and a discharging area are sequentially distributed on the welding base in the rotating direction of the welding turntable. The welding system has the advantages that the welding base and the welding turntable are matched to serve as a conveying basis, in cooperation whit arrangement of different areas including the feeding area, the preheating area, the welding area, the cooling area and the discharging area, automatic welding of a valve body, a valve deck and a copper connecting pipe and assembly line type continuous welding production are achieved, manual welding is not needed, the labor intensity of workers is greatly reduced, the stability of the welding quality is ensured, and the production efficiency is improved.

Owner:NANTONG OEM REFRIGERATION EQUIP

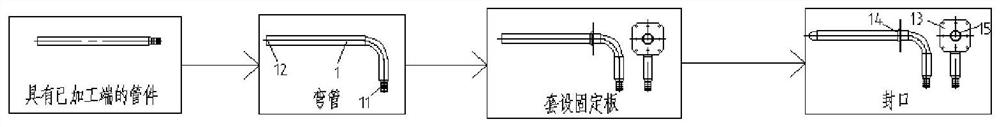

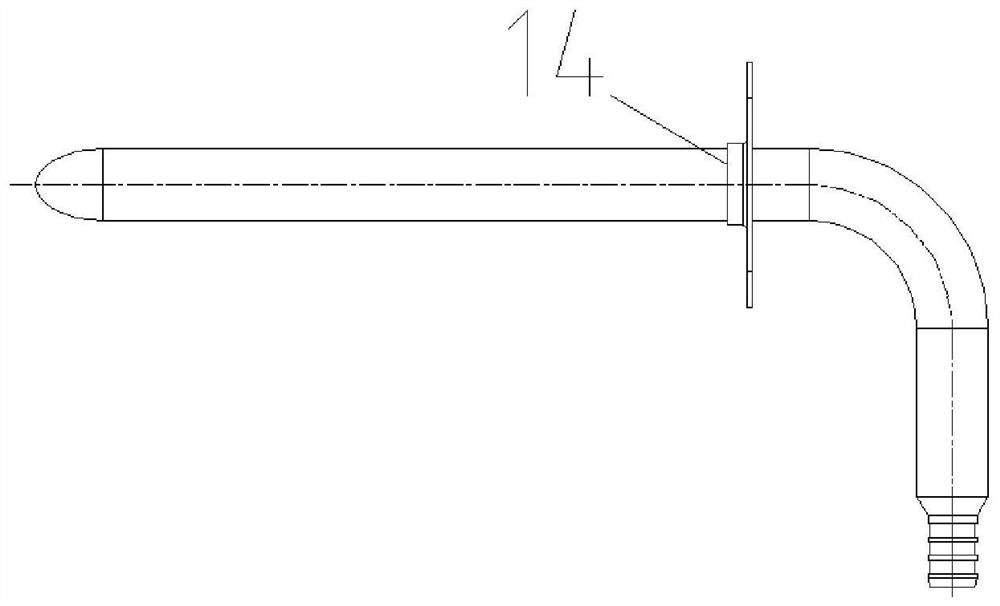

Processing method of detection pipe

ActiveCN114789211ASave shipping timeNo manual operationNuclear energy generationPipe fittingEngineering

The invention provides a machining method of a detection pipe. The machining method comprises the following steps that a pipe fitting is bent; the pipe fitting obtained after pipe bending is completed is moved to a fixing plate feeding component in a fixing plate mounting device, and the axis of the pipe fitting is made to coincide with the axis of a mounting hole in a fixing plate; the first core rod sequentially penetrates through the mounting hole of the fixing plate and the interior of the pipe fitting, and then the fixing plate moves along the first core rod and is arranged on the outer side of the pipe fitting in a sleeving mode; the pipe fitting sleeved with the fixing plate is moved to a dotting station, and a fixing ring on one side of the fixing plate is fixed to the pipe fitting through a second core rod and a plurality of dotting dies; performing necking treatment and sealing treatment on the to-be-processed end of the pipe fitting; the pipe fitting obtained after sealing machining is completed is moved to a discharging area through a translation device; when the to-be-machined end of the pipe fitting is sealed, the pipe fitting does not need to be welded and sealed, the pipe fitting machining efficiency is improved, and the labor cost and the equipment occupied area are reduced.

Owner:浙江长兴和良智能装备有限公司

A special welding device for partitions of power switch cabinets

ActiveCN106271288BImprove transmission stabilityStable supportWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderSwitchgear

The invention relates to a special welding device for a power switch cabinet interlayer. The special welding device comprises a moving support plate, a vertical plate is welded at the lower end of the moving support plate, two third hydraulic cylinders are symmetrically mounted on the inner wall of the vertical plate, the middles of the two third hydraulic cylinders are fixed on a T-shaped support column, so that the two third hydraulic cylinders are fixedly supported by the T-shaped support column, the T-shaped support column is welded on the moving support plate, a moving column is mounted at the top ends of the two third hydraulic cylinders through flanges, the upper end of the moving column is symmetrically mounted on two linear sliding rails, two ends of each linear sliding rail are mounted on the lower end surface of the moving support plate, the two third hydraulic cylinders can stably drive the moving column to bilaterally move through the two linear sliding rails, and a mounting plate is mounted at the lower end of the moving column. The special welding device can automatically and rapidly weld a switch cabinet interlayer, is simple and convenient to operate and has the advantages that the welding device is high in welding speed, good in welding quality and high in welding efficiency, and manual operation and manual welding are omitted and the like.

Owner:YANCHENG POWER SUPPLY CO STATE GRID JIANGSU ELECTRIC POWER CO +4

Flange welding and lamp door cutting integrated intelligent production line

ActiveCN114682916ASimple and fast operationNo manual welding requiredWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingManufacturing engineering

The invention relates to a flange welding and lamp door cutting integrated intelligent production line which comprises a lamp pole supporting device, a lamp door cutting device, a flange positioning device, a first welding device, a rib plate positioning and pressing device and a second welding device. The lamp door cutting device comprises a ground rail extending in the first direction, a sliding frame arranged on the ground rail in a sliding mode and a laser cutting mechanism arranged on the sliding frame. The flange positioning device comprises a supporting frame and a chuck rotationally arranged on the supporting frame. The first welding device comprises a first lifting mechanism and a first welding gun; the rib plate positioning and pressing device comprises a door-shaped frame, a second lifting mechanism arranged on the door-shaped frame, a positioning mechanism arranged at the output end of the bottom of the second lifting mechanism and a pressing mechanism arranged at the output end of the bottom of the second lifting mechanism. Lamp door cutting, flange welding and rib plate welding of the lamp pole can be completed at a time, operation is easy and convenient, manual welding is not needed, and the working efficiency and the use reliability are improved.

Owner:JIANGSU TEWEI MACHINE TOOL MFG

Welding clamp of lithium ion battery breaker

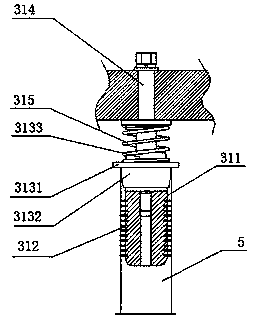

ActiveCN102773648BReasonable structural designEasy to manufactureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

Owner:NINGDE AMPEREX TECH

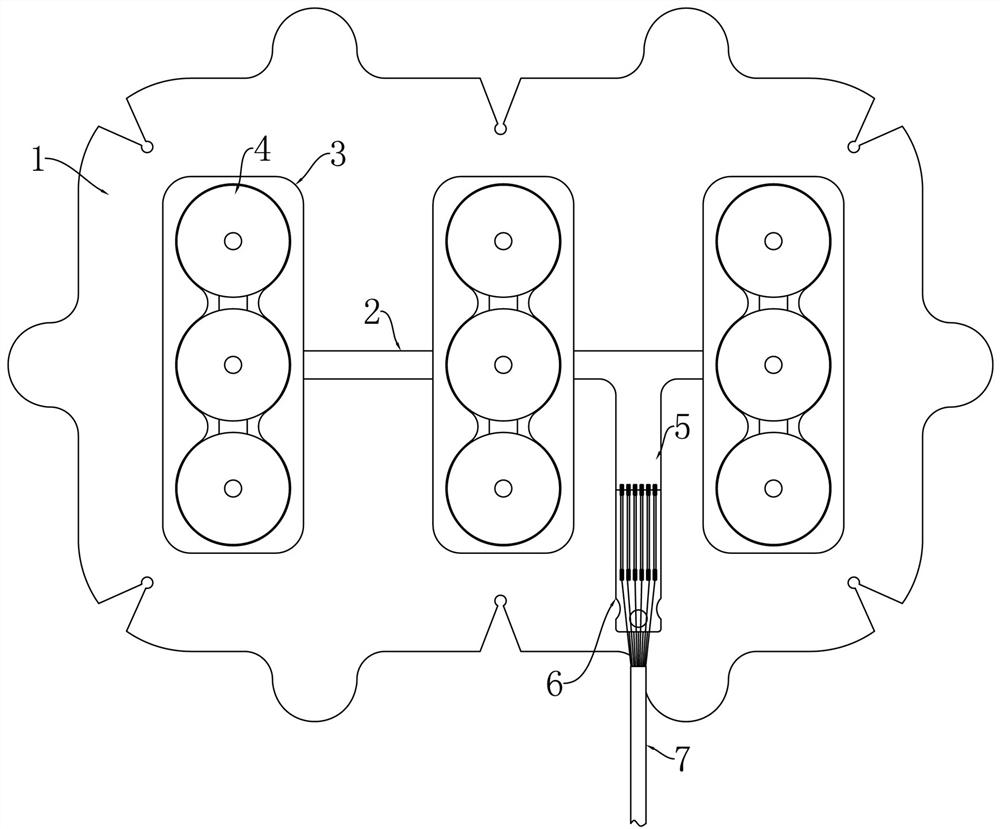

A planting core laser welding device

ActiveCN109365938BAvoid displacementImprove brazing qualitySoldering auxillary devicesEngineeringLaser soldering

A planting core laser welding device, including a frame, a welding mechanism, a gripper mechanism and a transmission mechanism that drives the movement of the gripper mechanism; a platform for placing panels is provided on the frame; the welding mechanism and the transmission mechanism are connected to the frame The welding mechanism includes a linear slide and a welding head for welding the core tube to the panel, and the linear slide drives the welding head to move; the gripper mechanism includes a clamping part for clamping the core tube. The invention enables the core tube to be automatically welded on the panel, thereby preventing the core tube from shifting due to air flow during the brazing process, the conveying process, or the process of laying the upper panel, thereby improving the brazing quality; and without manual welding, greatly Improve work efficiency and reduce labor costs.

Owner:远大可建科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com