Plant core laser welding device

A laser welding and core planting technology, which is applied in the direction of auxiliary devices, welding equipment, metal processing equipment, etc., can solve the problems of affecting the brazing quality, the core tube is crooked, and the solder is blown crookedly, so as to improve the brazing quality and not The effect of lower pass rate and lower labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

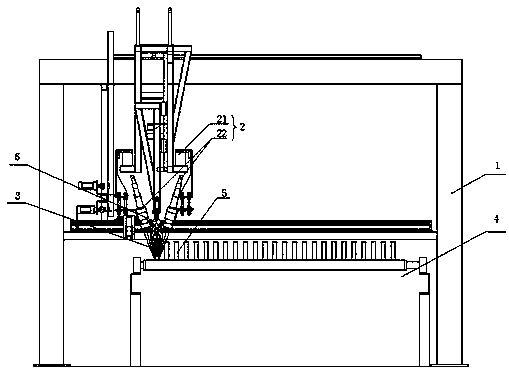

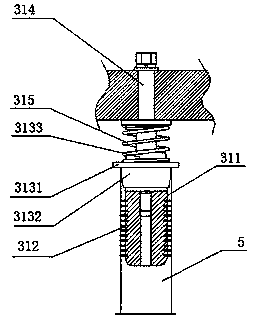

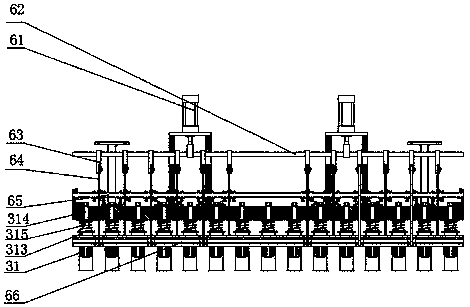

[0038] Such as figure 1 Shown: a planting core laser welding device, including a frame 1, a laser welding mechanism 2 and a gripper mechanism 3. Among them, the laser welding mechanism 2 includes a linear slide table 21 and two laser welding heads 22, the linear slide table is connected to the frame through a support frame and some fixing parts, the linear slide table 21 is connected with the laser welding head 22, and can simultaneously Drive the two laser welding heads for linear motion. A platform 4 for placing panels is provided below the laser welding machine head. The handle mechanism 3 includes a plurality of brush bodies 31 for grabbing the core tubes, and the adjacent brush bodies are arranged at intervals, which is the same as the arrangement spacing of each core tube 5 on the panel, and the upper part of the brush bodies passes through The mounting seat is connected with a transmission mechanism, and the transmission mechanism is used to drive the brush body to mo...

Embodiment 2

[0048] The difference from Embodiment 1 is that this embodiment does not have a core tube guiding mechanism, and if the core tube is found to be tilted, it can be manually guided.

Embodiment 3

[0050] The difference from Embodiment 1 is that this application only has one laser welding head, and only welds the front side of the core tube, or only welds the back side of the core tube, as long as the core tube is fixed on the panel, no displacement will occur That's it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com