Lower cone body of cerement bin and manufacturing process of lower cone body

A manufacturing process and technology of cement silo, applied in the field of machinery, can solve the problems of long production cycle of silo, harsh working environment, waste of solder resources, etc., to achieve the improvement of processing accuracy and product quality and aesthetics, consistent size of silo body, Environmentally friendly processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

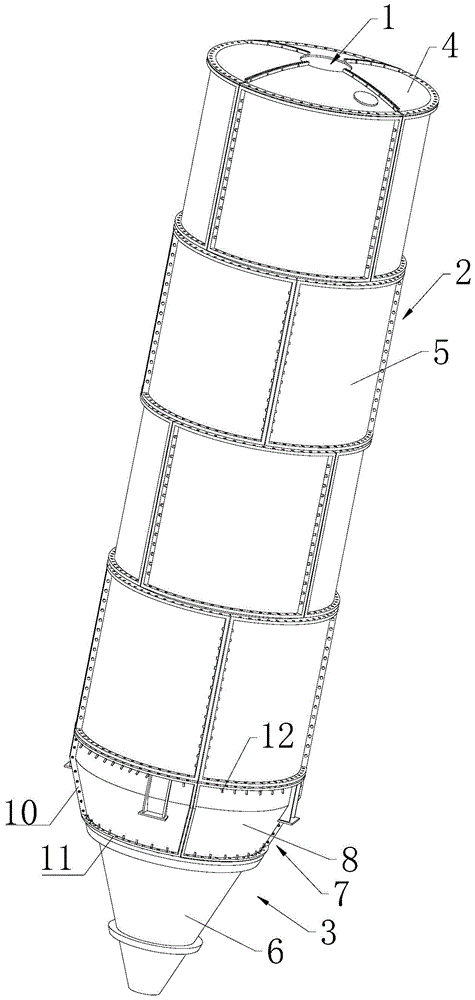

[0018] Such as figure 1 As shown, the cement silo includes, from top to bottom, an upper cone 1, a middle cylinder 2, and a lower cone 3 connected by fasteners; the upper cone 1 includes several upper cone splicing modules 4 of the same size, Several upper cone splicing modules 4 are assembled to form the upper cone 1 ;

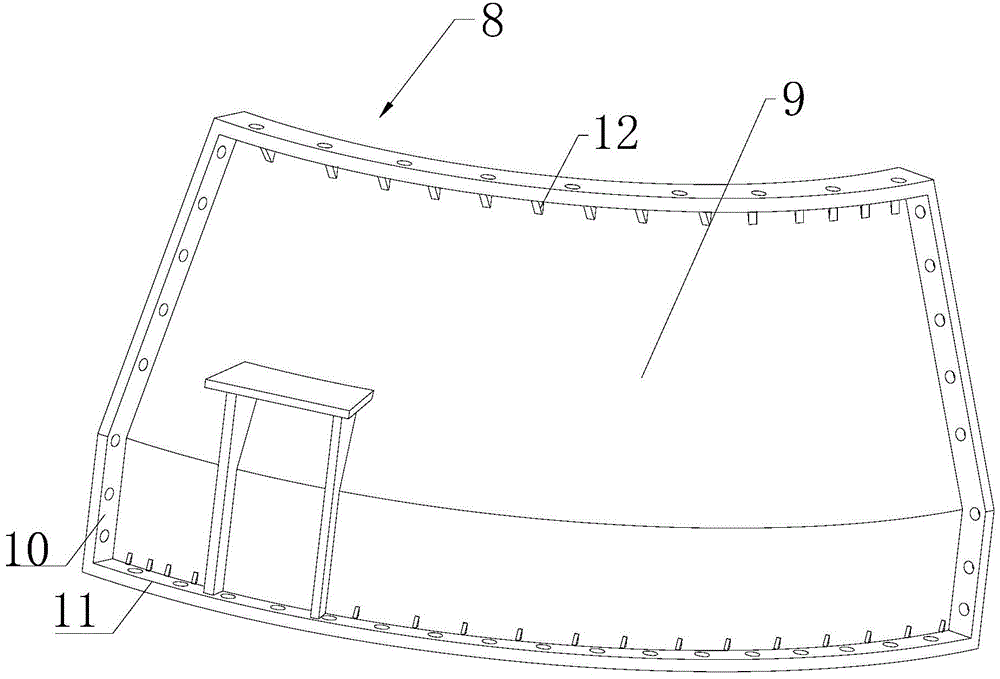

[0019] Such as figure 2 As shown, the lower cone 3 includes an end cone 6 and at least one conical cylinder 7, the conical cylinder 7 and the end cone 6 are installed together by fasteners, and the conical cylinder 7 includes several conical cylinder splicing modules 8 , a number of conical cylinder splicing modules 8 are assembled to form a conical cylinder 7, each conical cylinder splicing module 8 includes a conical cylinder splicing module body 9, and the left and right sides of the conical cylinder splicing module body 9 are respectively provided with an integrated hydraulic press. The conical cylinder strip flange 10 formed by molding, the conical cy...

Embodiment 2

[0025] The manufacturing process of the lower cone of the cement silo includes the following steps:

[0026] S1, making the end cone 6 and the conical cylinder splicing module 8; the end cone 6 is welded, and a number of trapezoidal metal plates required for making the conical cylinder splicing module 8 are cut out with a numerical control machine tool, and the left and right sides of the conical cylinder are cut out. The trapezoidal metal sheet required by the body splicing module 8 is drilled with a drilling die, and then the trapezoidal metal sheet is bent into an arc shape by a hydraulic press with the conical barrel splicing module stamping die, and the two sides of the metal sheet are punched out into strips shaped flange, and then the strip flanges on both sides are fixed, the upper and lower ends of the metal sheet are welded with arc-shaped flanges, and finally the two shaped flanges are loosened, and a conical cylinder splicing module 8 is completed;

[0027] S2. Ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com