Rotary welding torch automatic welding robot

An automatic welding and spin welding technology, applied in welding equipment, welding accessories, welding rod characteristics, etc., can solve the problems of long assembly time, high labor intensity, automatic positioning welding, etc., and achieve the effect of improving function and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

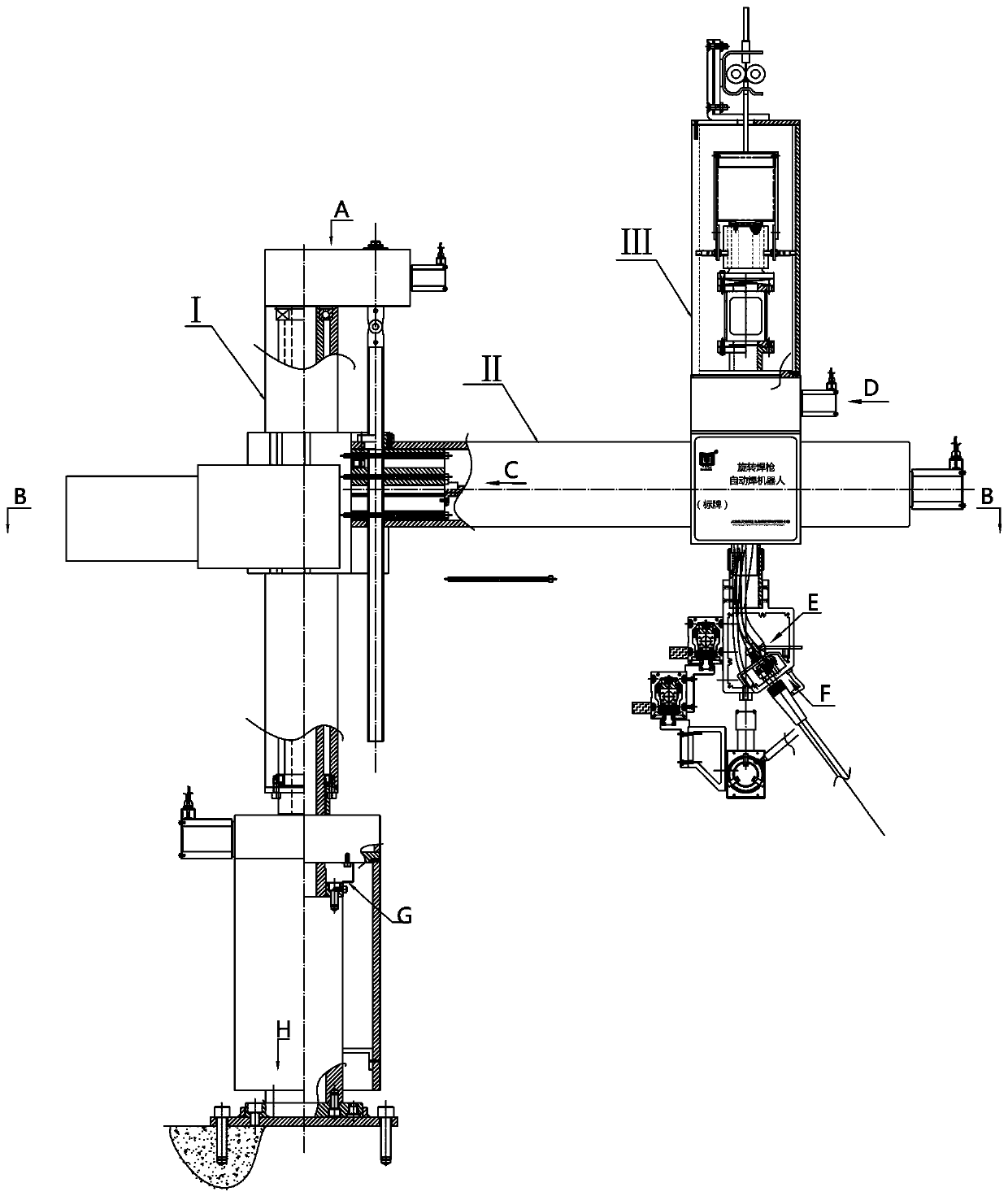

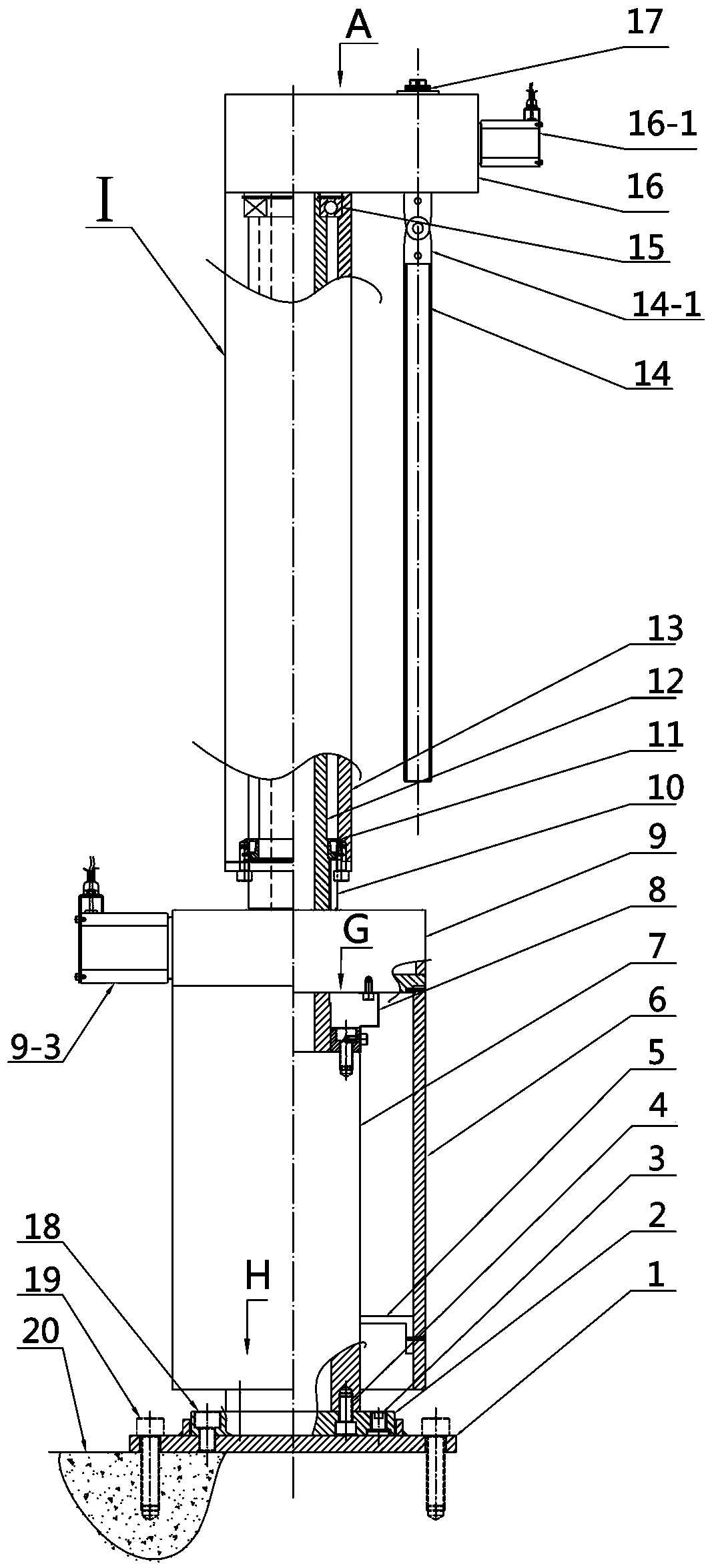

[0036] see Figure 1 to Figure 4-5 , The rotary welding torch automatic welding robot of the present invention is composed of three parts: a column part, a cantilever beam part, and a rotary welding torch slide seat part.

[0037] The column part is vertically assembled and fixed on the ground, the cantilever beam part is assembled on the column part, and the rotary welding torch sliding seat part is assembled on the cantilever beam part.

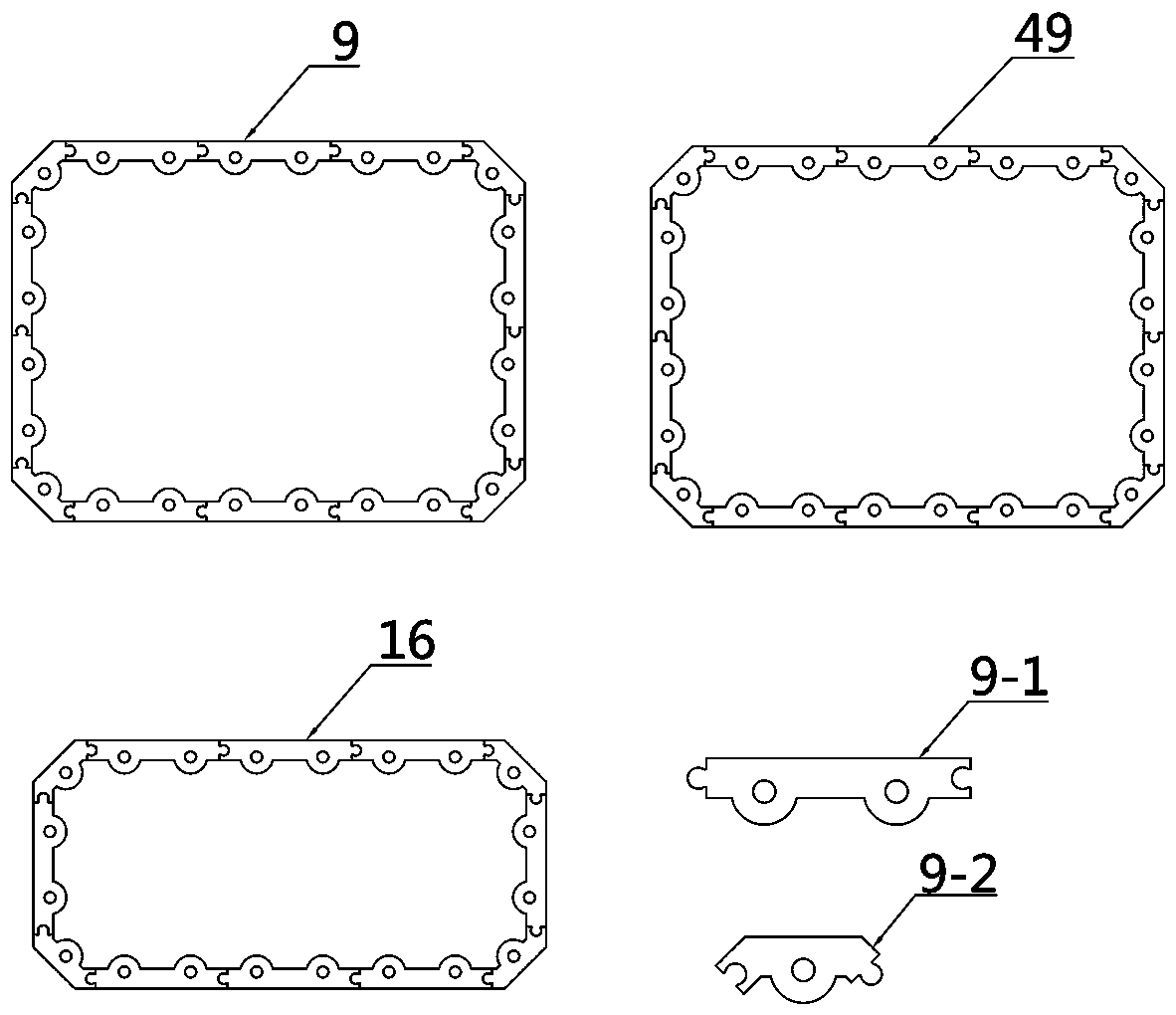

[0038] For the column parts, the column bottom plate 1 is fixed on the ground by bolts 19, the column base 7 and the column base flange 2 are connected by bolts 4, and the top wire 3 is adjusted by adjusting the verticality of the column, and after the verticality of the column is adjusted in a suitable position , the column base and the column bottom plate 1 are connected and fixed by bolts 18, the upper end of the column base 7 is flanged to the column center shaft 12, and the hollow shaft of the column rotation deceleration 9 is sleeved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com