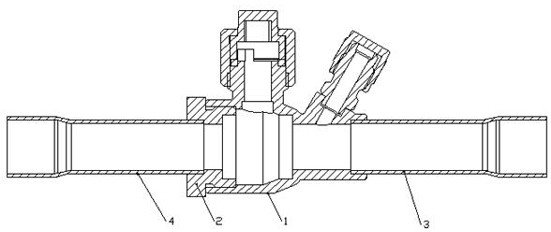

Welding system for ball valve of refrigerating system

A welding system and refrigeration system technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to realize continuous production, quality influence of welding, unstable welding quality, etc., to avoid adverse effects and improve Production efficiency, good welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

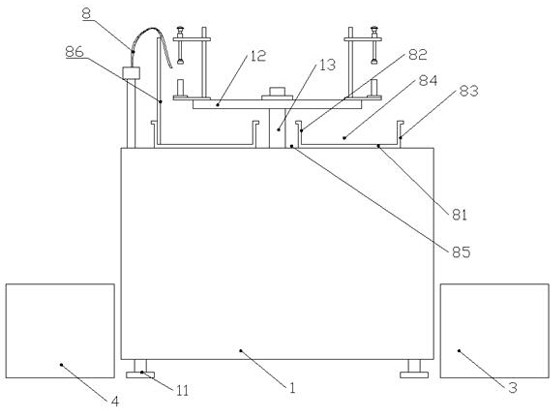

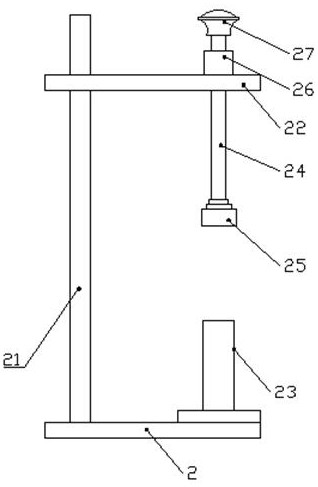

[0034] Such as Figure 2-Figure 8 A welding system for a refrigeration system ball valve is shown, including

[0035]A welding base 1, the welding base 1 is a cuboid box structure, the bottom end of the welding base 1 is supported by four rectangular-shaped distribution feet 11, and a welding turntable 12 is installed on the upper end surface of the welding base 1 The welding turntable 11 is driven to rotate by the welding motor installed on the welding base 1. The welding motor is installed inside the welding base 1. The welding motor and the welding turntable 12 are connected by a transmission shaft 13 for transmission. On the welding turntable 11 Several workpiece placement seats are arranged side by side along the circumferential direction of the welding turntable 12 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com