Steel tube manufacturing method

A manufacturing method and technology of steel pipes, which are applied in the field of steel pipe manufacturing, can solve problems such as the weak load-bearing capacity of steel pipes and affect the service life of steel pipes, and achieve the effects of enhanced load-bearing capacity, extended service life, and reduced use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

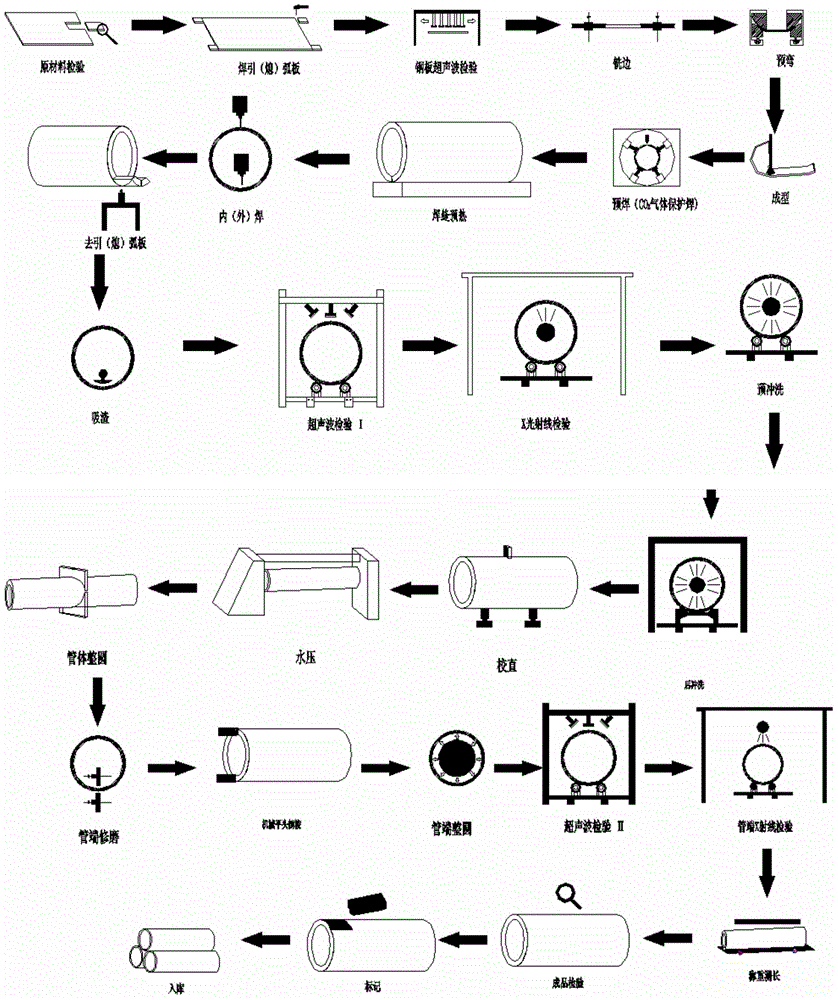

[0030] The manufacturing method of steel pipe of the present invention, its flow chart structural diagram is as figure 1 shown, including the following steps:

[0031] The new material Q345GJC-Z15 pipeline is used, which includes the following components by mass percentage: C≤0.20; Si≤0.55; Mn≤1.60; P≤0.025; S≤0.015; V 0.020-0.150; Nb 0.015-0.060; 0.010; Ti 0.010-0.030; Als≥0.015; Cr≤0.30; Cu≤0.30; Ni≤0.30; the balance is matrix Fe;

[0032] The raw material of the steel plate is inspected by the ultrasonic flaw detection method;

[0033] Arc extinguishing plate welding: arc extinguishing plates are welded at both ends of the steel plate to reduce quality problems in pipe welding;

[0034] Steel plate surface cleaning: remove floating rust on the steel plate surface;

[0035] Edge milling of the steel plate: Mill the steel plate with the corresponding knife to make the upper and lower grooves, the angle of the upper groove is 40°±0.5, the angle of the lower groove is 35°±0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com