Method and equipment for improving latent heat utilization rate in seawater desalination

A latent heat and equipment technology, applied in the field of improving latent heat utilization efficiency in seawater desalination, can solve problems such as long condensation pipes, reduced temperature difference, and inability to transfer heat out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

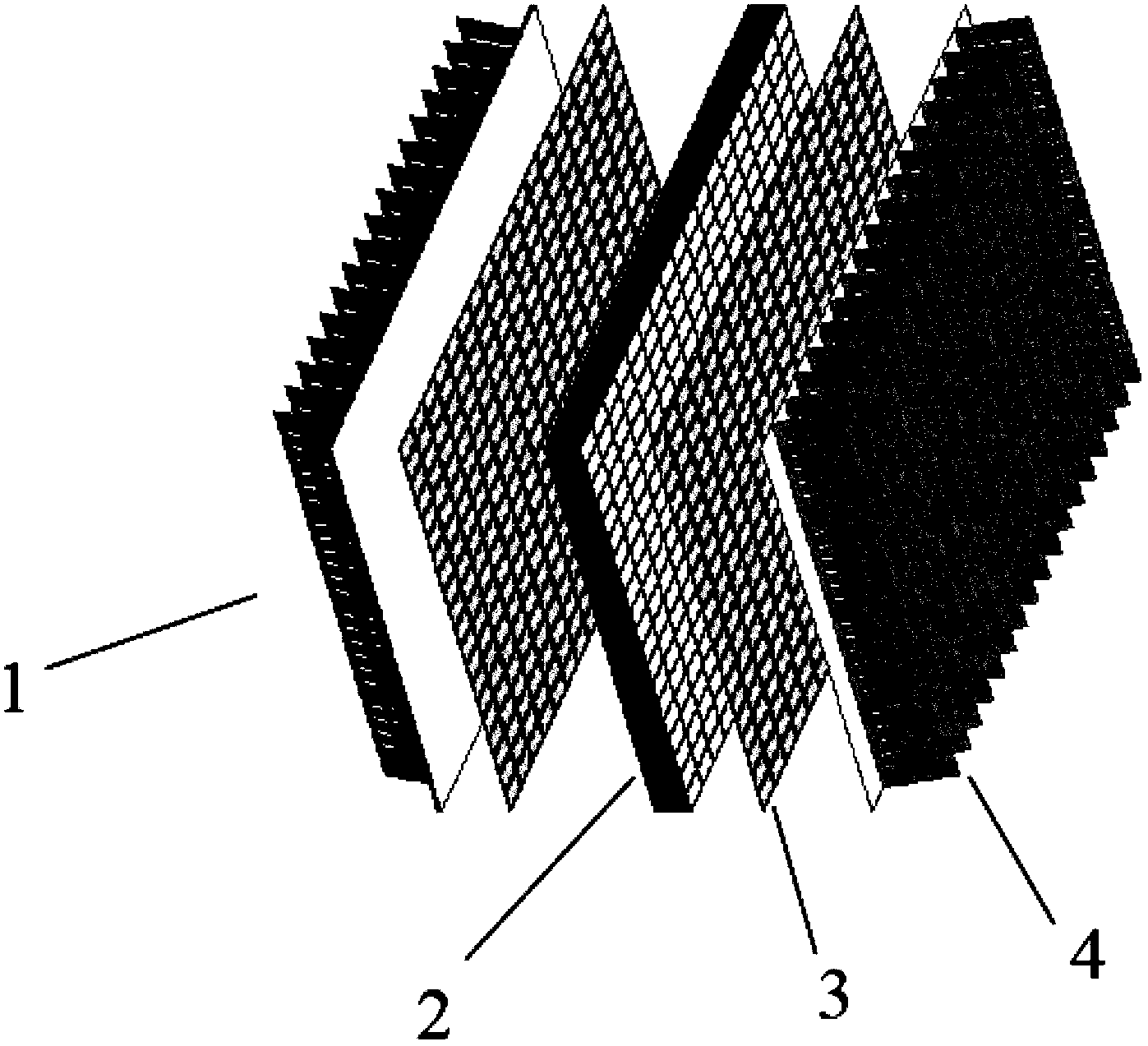

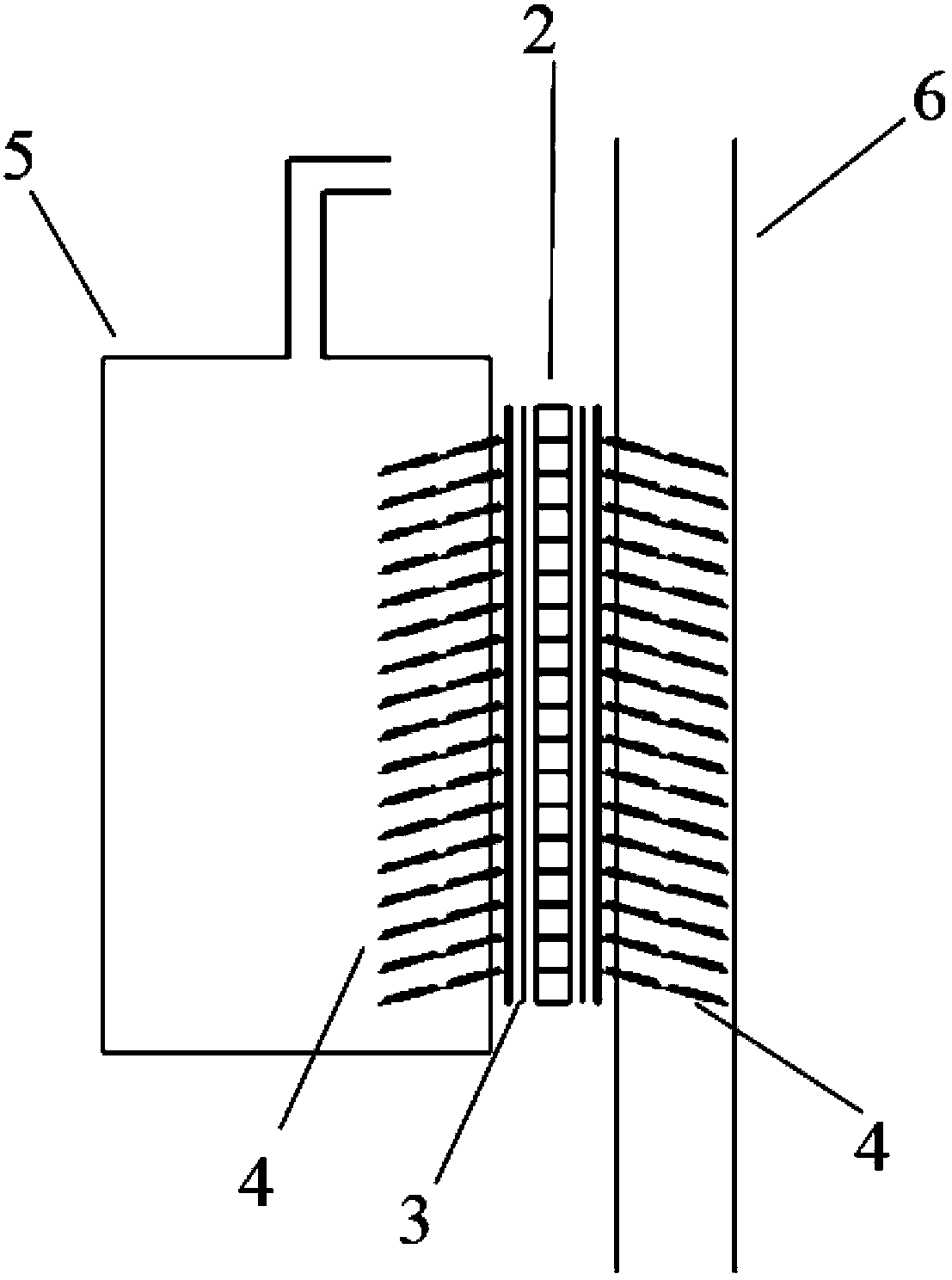

[0045] A small principle prototype was fabricated, referring to figure 2 The structure, in the front section of the seawater preheating box, the working medium is a mixture of seawater and air. MPa, the temperature of the mixture in the pipeline is 80°C; the temperature of the water vapor mixture at the inlet of the condenser is 130°C, the size of the thermoelectric device is 50mmx50mmx4mm, and a thermoelectric device is placed, the total latent heat power of the water vapor mixture is 109.7W. It has been measured that the electric power consumed by the thermoelectric device is 13.2W, the heat released at the hot end of the thermoelectric device is 129.6W, and the heat absorbed at the cold end is 116.8W, recovering 106.5% of the latent heat of condensation of water vapor (including part of the single-phase liquid water released by cooling heat). After the same measurement, if there is no thermoelectric device, only 17.2W of heat can be absorbed under the same conditions, whi...

Embodiment 2

[0047] refer to figure 2 The working medium is a mixture of seawater and air in the front pipeline of the seawater preheating box, the flow rate of seawater at normal temperature and pressure is 8mL / min, the flow rate of air is 800mL / min, the working pressure is 0.1MPa, and the temperature of the mixture in the pipeline is 80 °C; the temperature of the water vapor mixture at the inlet of the condenser is 130 °C, the size of the thermoelectric device is 50mmx50mmx4mm, and three thermoelectric devices are placed, the total latent heat power of the water vapor mixture is 292.6W. According to the measurement, the electric power consumed by the thermoelectric device is 65.2W, the heat output at the hot end of the thermoelectric device is 308.8W, the heat absorption at the cold end is 244W, and 83.4% of the latent heat of condensation of water vapor is recovered. After the same measurement, if there is no thermoelectric device, only 54.4W of heat can be absorbed under the same cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com