Welded fastening method of short-circuited conducting sleeve and adoptive short-circuited conducting sleeve thereof

A fixing method and short-circuit ring technology, applied in the field of short-circuit rings, can solve the problems of complicated electroless copper plating process, gas shielded welding gap, and weak fixing of the short-circuit ring, etc., so as to achieve a simple and easy welding fixing method, uniform solder joints, The effect of improving the service life and safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

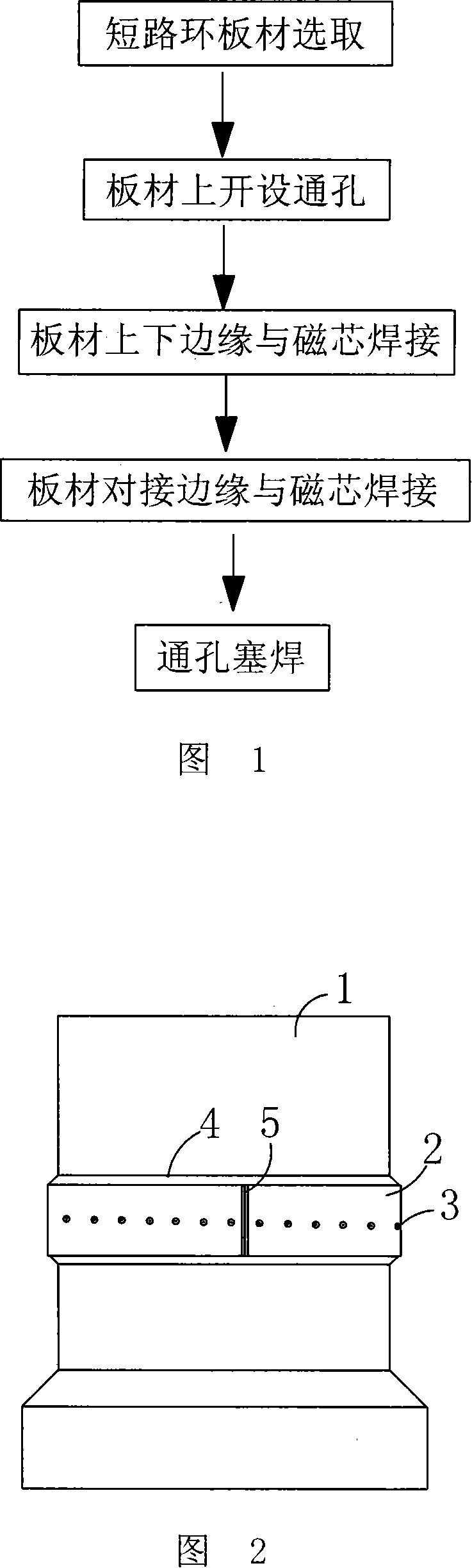

[0030] Embodiment 1 Fig. 1 shows the step block diagram of the preparation of the first short-circuit ring and its welding and fixing method, and the specific steps are as follows:

[0031] Plate selection: choose copper plate with relatively low resistivity as the short-circuit ring material. The thickness of the copper plate is 8 mm, which is a rectangular plate. The two side edges 5 of the plate are used as the butt end faces, and the shape is a V-shaped cross-sectional groove, as shown in Figure 3 shown.

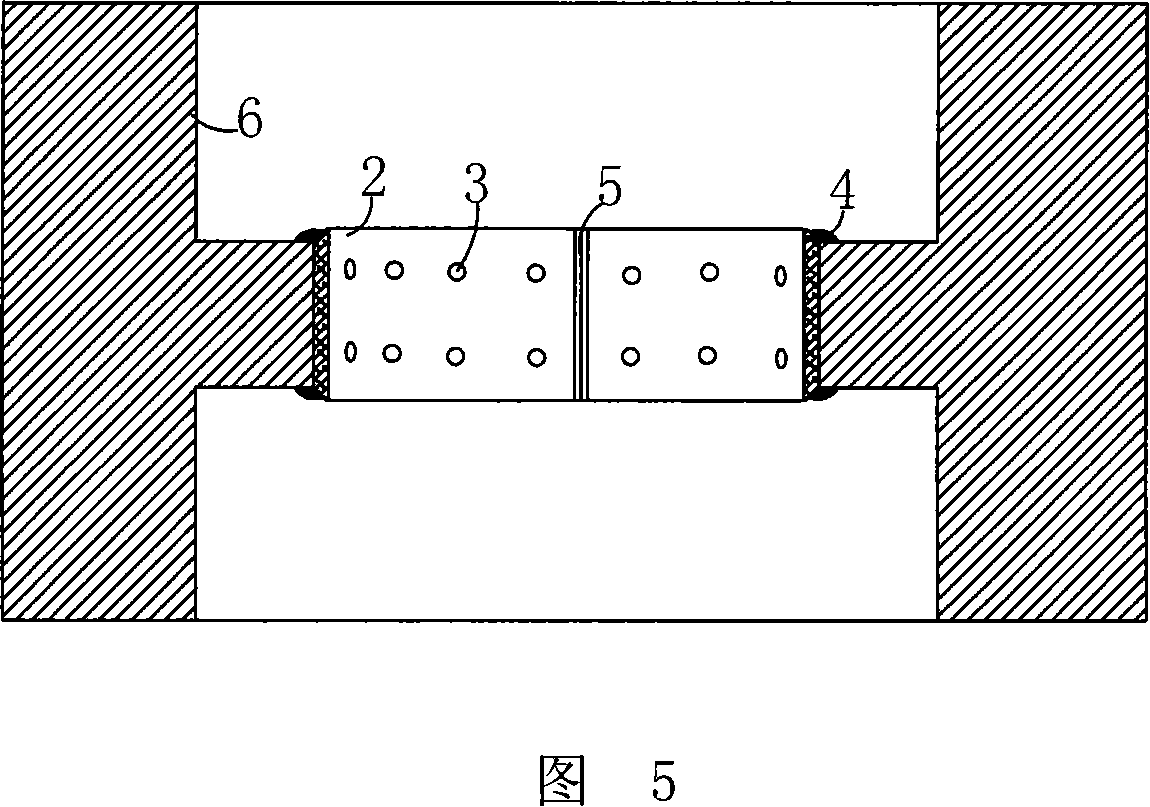

[0032] Opening of through holes: Drill holes on the copper plate. The through holes are tapered holes with a maximum inner diameter of about 50mm. The through holes are evenly arranged and distributed along the middle of the plate. For the magnetic core cleaning of plates, welding wires and vibrating tables, the cathode cleaning method is used to remove the oxide film on the surface of the short-circuit ring and the welding wire, to prevent the generation of bubbles and ...

Embodiment 2

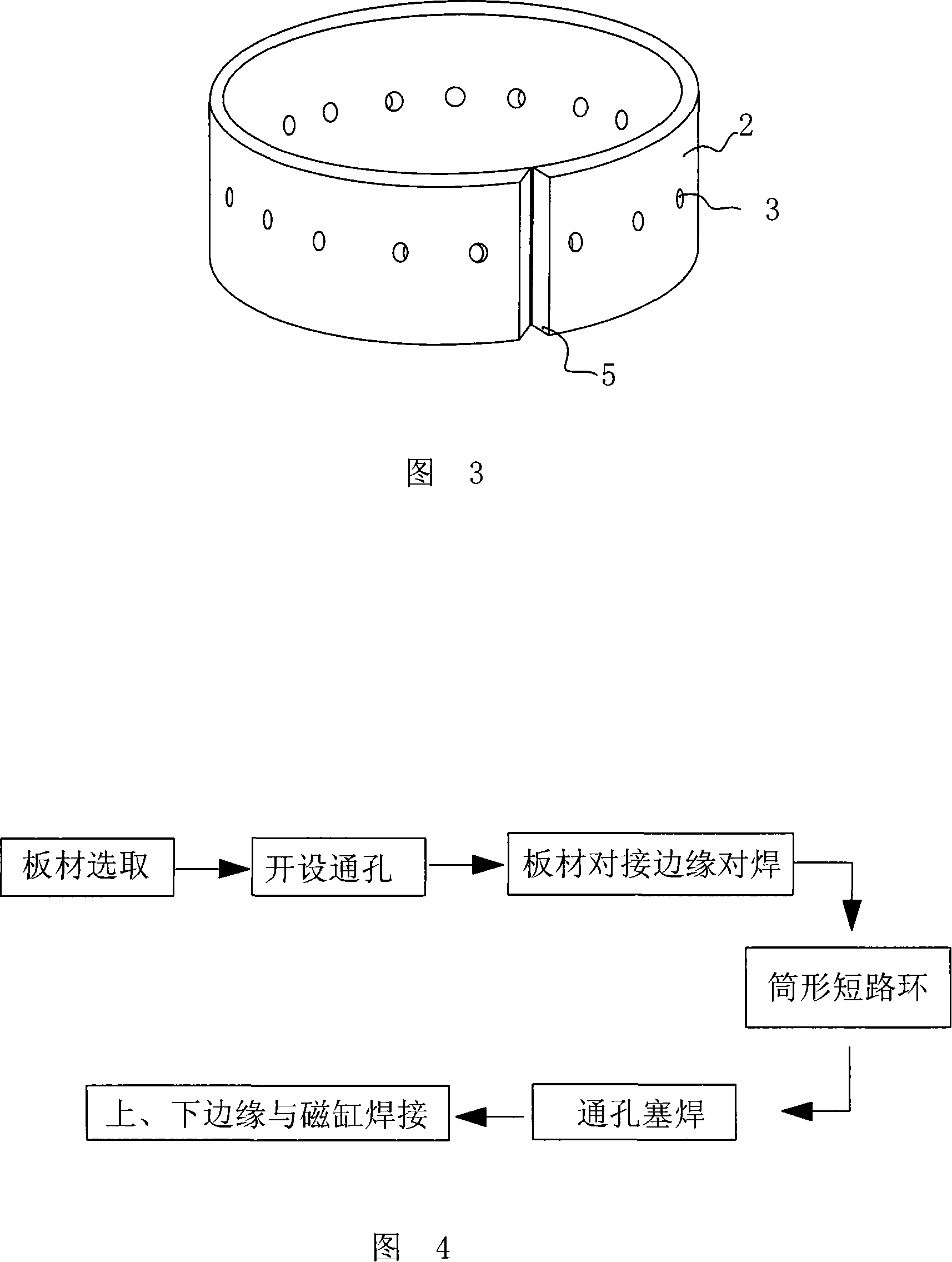

[0035] Embodiment 2 Fig. 3 shows the block diagram of the steps of the preparation of the second short-circuit ring and its welding and fixing method, and the specific steps are as follows:

[0036] Plate selection: choose a copper plate with a relatively low resistivity as the short-circuit ring material. The thickness of the copper plate is 3mm. It is a rectangular plate, and the two side edges of the plate are used as the butt end faces.

[0037] Opening of through holes: Drill holes on the copper plate. The through holes are tapered holes with a maximum inner diameter of about 50mm. The through holes are evenly arranged and distributed along the middle of the plate. For the magnetic core cleaning of plates, welding wires and vibrating tables, the cathodic cleaning method is used to remove the oxide film on the surface of the short-circuit ring and welding wire, to prevent bubbles and slag during welding, and to remove the grease, coating and processing on the surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com