Rock-socketed hollow precast pile and rock-socketed construction method using precast pile

A technology of prefabricated piles and hollow piles, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of steep inclination of bedrock surface, uneconomical, complicated procedures, etc. Good quality controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

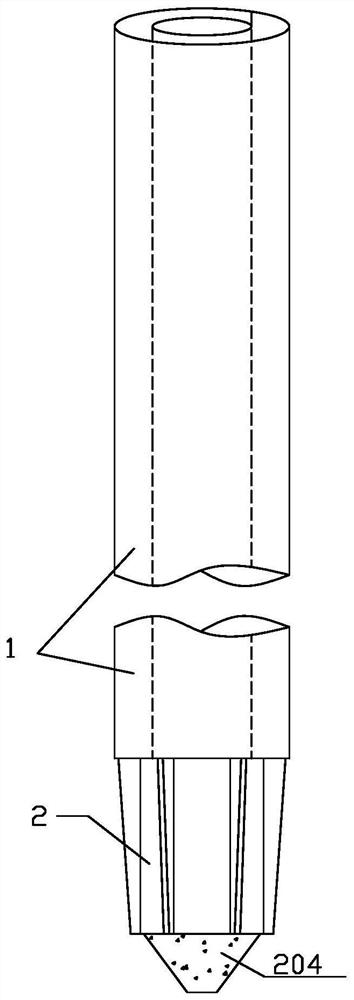

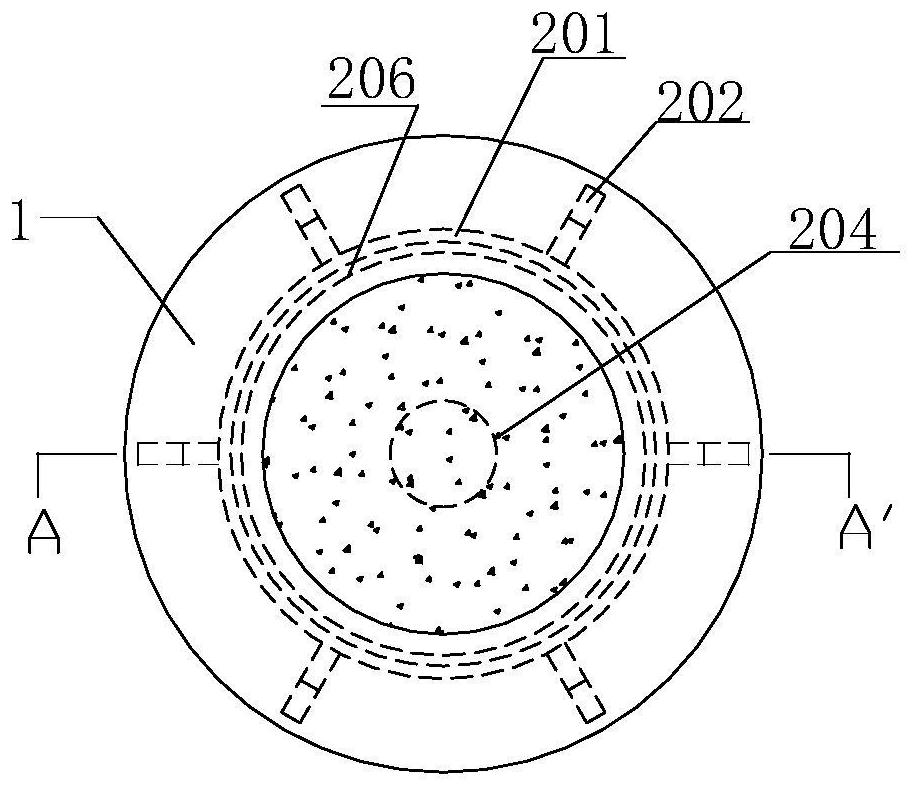

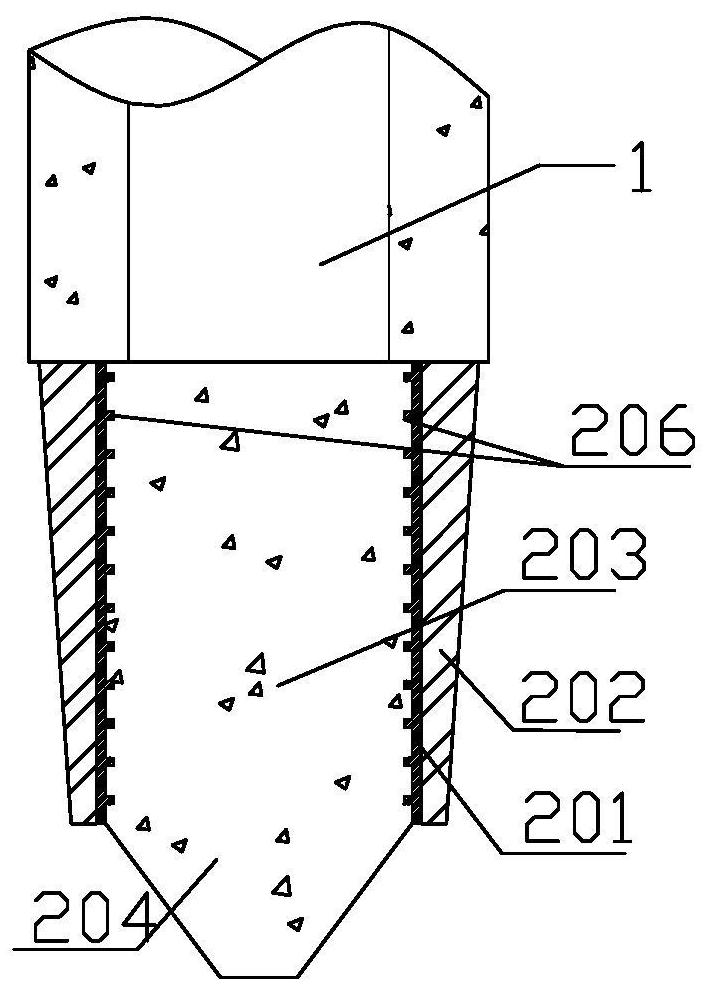

[0064] The rock-socketed construction method provided in Example 1 is to use hammering pile sinking equipment, prefabricated pipe piles use prestressed pipe piles, and the force-transmitting skeleton adopts steel reinforcement skeletons. Marine silt, gravel residual soil, hard bedrock. Concrete implementation steps are as follows:

[0065] (1) Excavate large rocks in the replacement site, level the site, and assemble hammering pile sinking equipment;

[0066] (2) Factory custom-made the first pile section with hollow prefabricated pile rock-socketed pile tips, cured until the strength reaches the design value, transported to the site, aligned according to the designed pile position, and adjusted the verticality;

[0067] (3) Hammer sinking into the first pile, when the top of the first pile is 50-100cm away from the ground surface, the pile is ready to be connected, and the pile is fully welded by air pressure shielded welding;

[0068] (4) Hammer pile-sinking piles section ...

Embodiment 2

[0073] The rock-socketed construction method provided in Example 2 is to use hammering pile sinking equipment, the prefabricated piles adopt prestressed pipe pile type, and the force transmission frame adopts the post-socketed rock-socketing method of steel skeleton (or steel cage). To throw and fill block rock soil, marine silt, pebble gravel residual soil, and hard bedrock, the specific implementation steps are as follows:

[0074] (1) Excavate large rocks in the replacement site, level the site, and assemble hammering pile sinking equipment;

[0075] (2) Factory custom-made the first pile section with hollow prefabricated pile rock-socketed pile tips, cured until the strength reaches the design value, transported to the site, aligned according to the designed pile position, and adjusted the verticality;

[0076] (3) Hammer sinking into the first pile, when the top of the first pile is 50-100cm away from the ground surface, the pile is ready to be connected, and the pile is ...

Embodiment 3

[0083] Embodiment 3 is a rock-socketing construction method after prefabricated reinforced concrete framework of hammering prestressed pipe piles, which is suitable for strata still filled with rocky soil, marine silt, pebble and gravel residual soil, and hard bedrock. The specific implementation steps as follows:

[0084] (1) Excavate large rocks in the replacement site, level the site, and assemble hammering pile sinking equipment;

[0085] (2) Factory custom-made the first pile section with hollow prefabricated pile rock-socketed pile tips, cured until the strength reaches the design value, transported to the site, aligned according to the designed pile position, and adjusted the verticality;

[0086] (3) Deeply prefabricate the inner core reinforced concrete (or steel reinforced concrete, or steel pipe concrete) force transmission framework according to the design requirements. The outer diameter of the force transmission framework is 40-80mm smaller than the nominal inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com