Radiating device

A technology of heat dissipation device and heat dissipation fins, which is applied to heat exchange equipment, indirect heat exchangers, lighting and heating equipment, etc. Stable performance and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

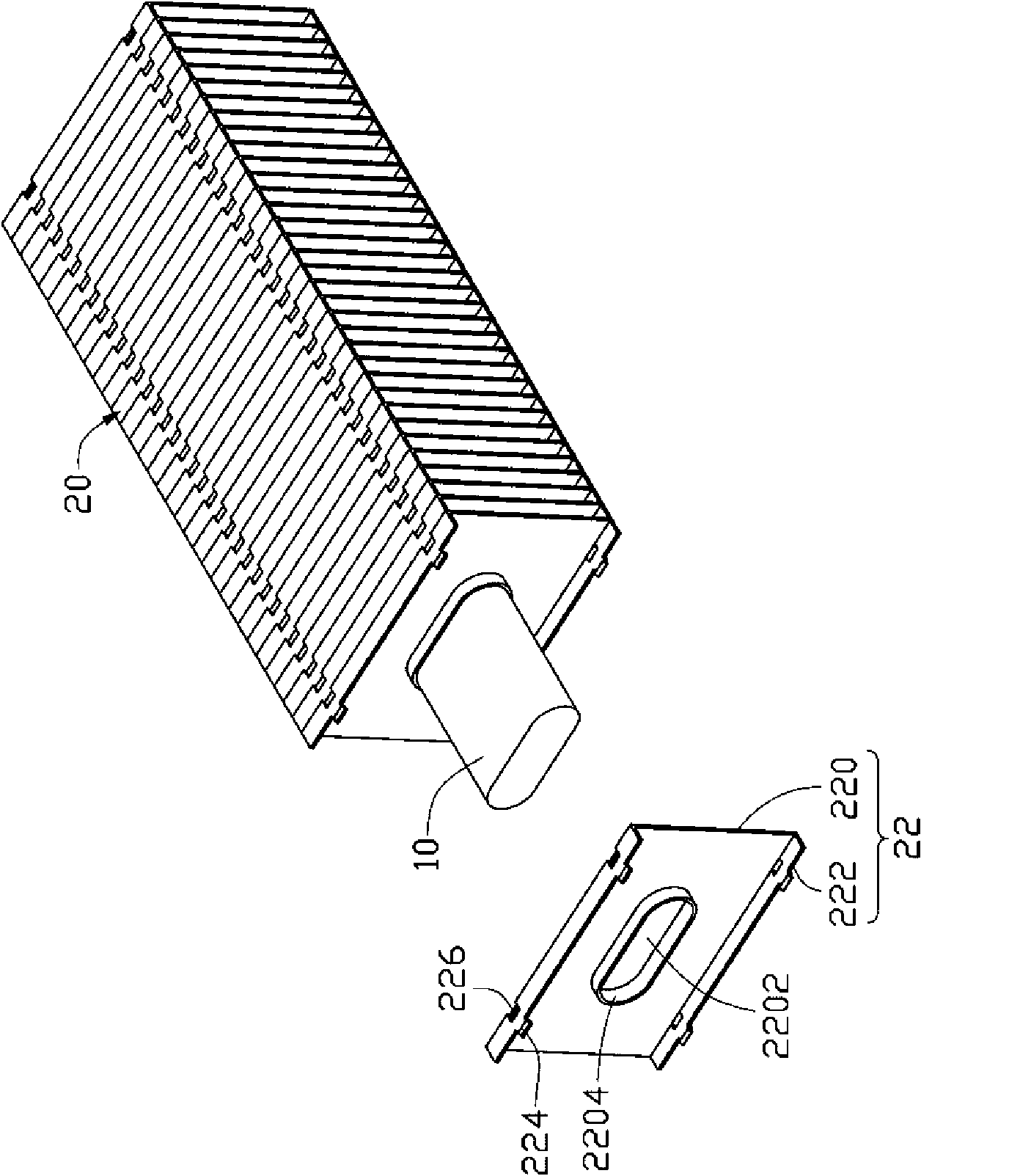

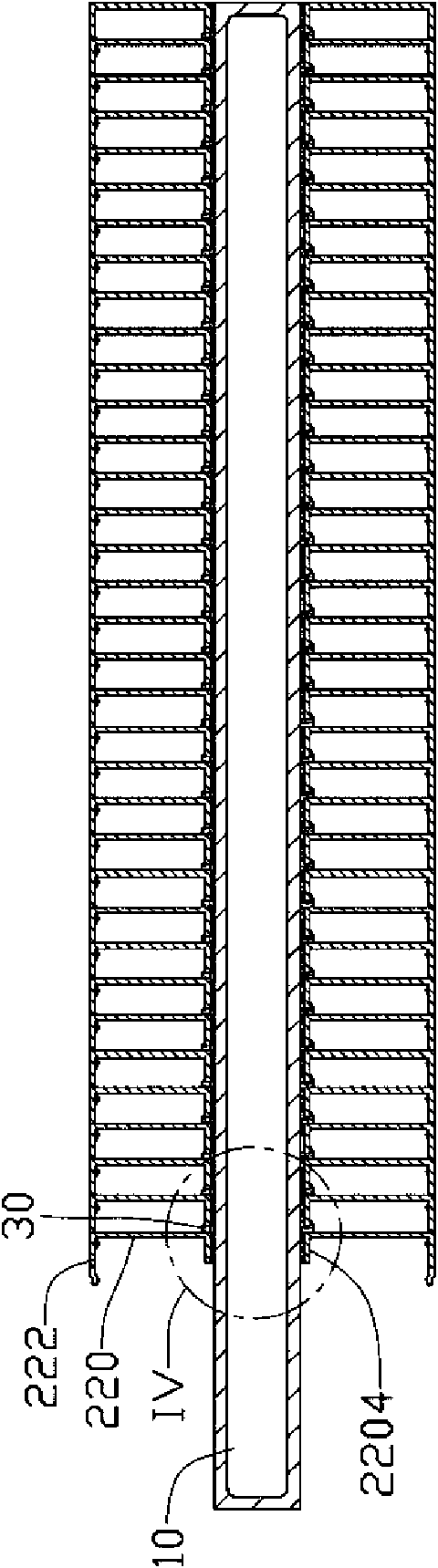

[0015] like figure 1 and figure 2 Shown is the first embodiment of the heat dissipation device of the present invention. The heat dissipation device includes a heat dissipation fin set 20 and a heat pipe 10 passing through the heat dissipation fin set 20 .

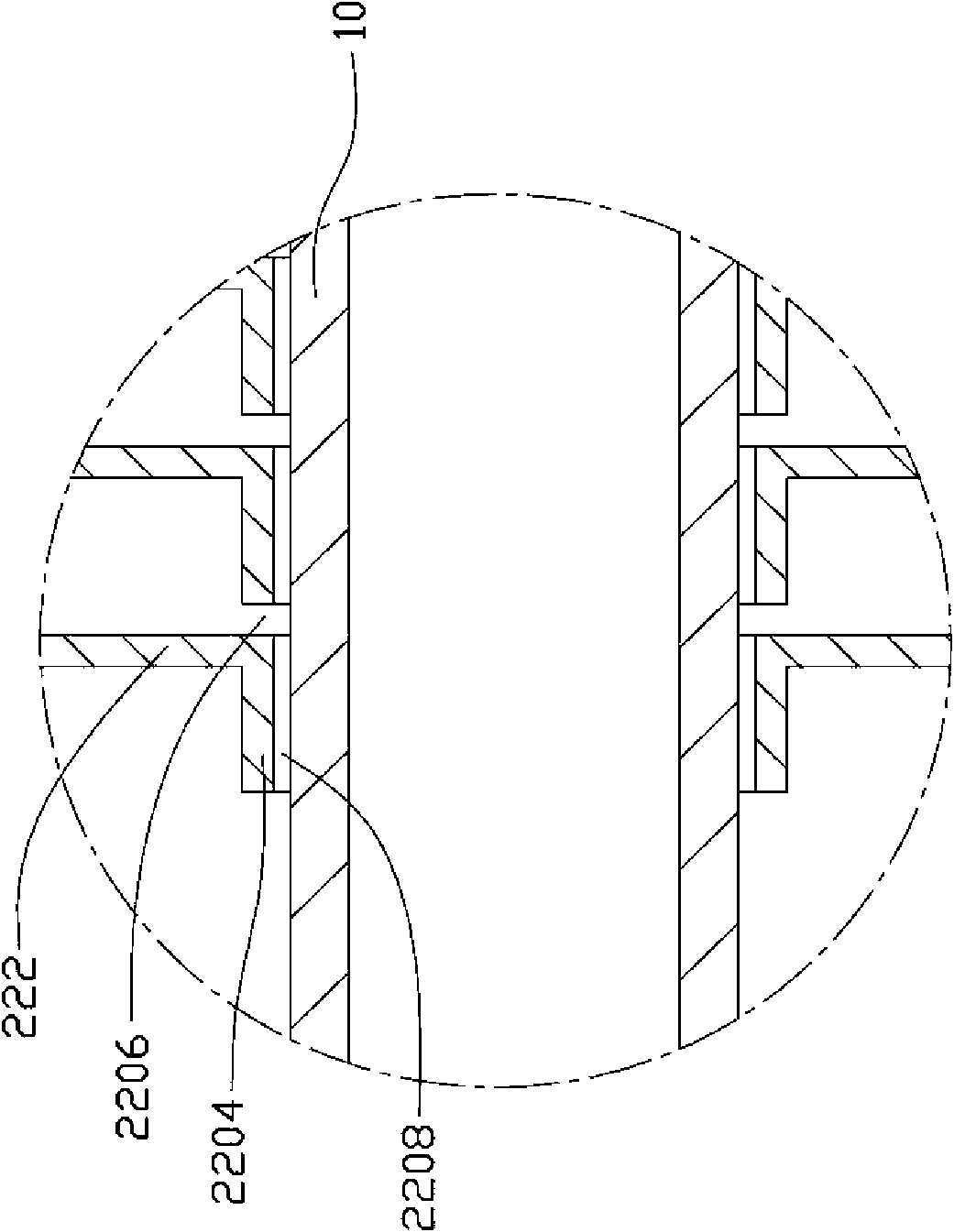

[0016] The heat pipe 10 is a flat heat pipe.

[0017] The heat dissipation fin set 20 is formed by a plurality of heat dissipation fins 22 arranged in sequence. The heat dissipation fins 22 are parallel to each other, and every two adjacent heat dissipation fins 22 are spaced an equal distance from each other to form an airflow channel. Each cooling fin 22 includes a body 220 and two folded edges 222 respectively bent from the top and bottom of the body 220 to one side. The folded edges 222 are perpendicular to the body 220. Each folded edge 222 includes a fixed end connected to the main body 220 and a free end extending outward from the fixed end. The widths of the two folded edges 222 are equal. The side 222 has a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com