Aluminum alloy door and window achieving hidden type trace water drainage

A hidden technology for aluminum alloy doors and windows, which is applied in windows/doors, condensed water discharge, and condensed water formation prevention, etc. It can solve the problems of easy-to-corrode slide rails, poor drainage effect, and increase user's operating burden, etc., to achieve excellent heat conduction performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

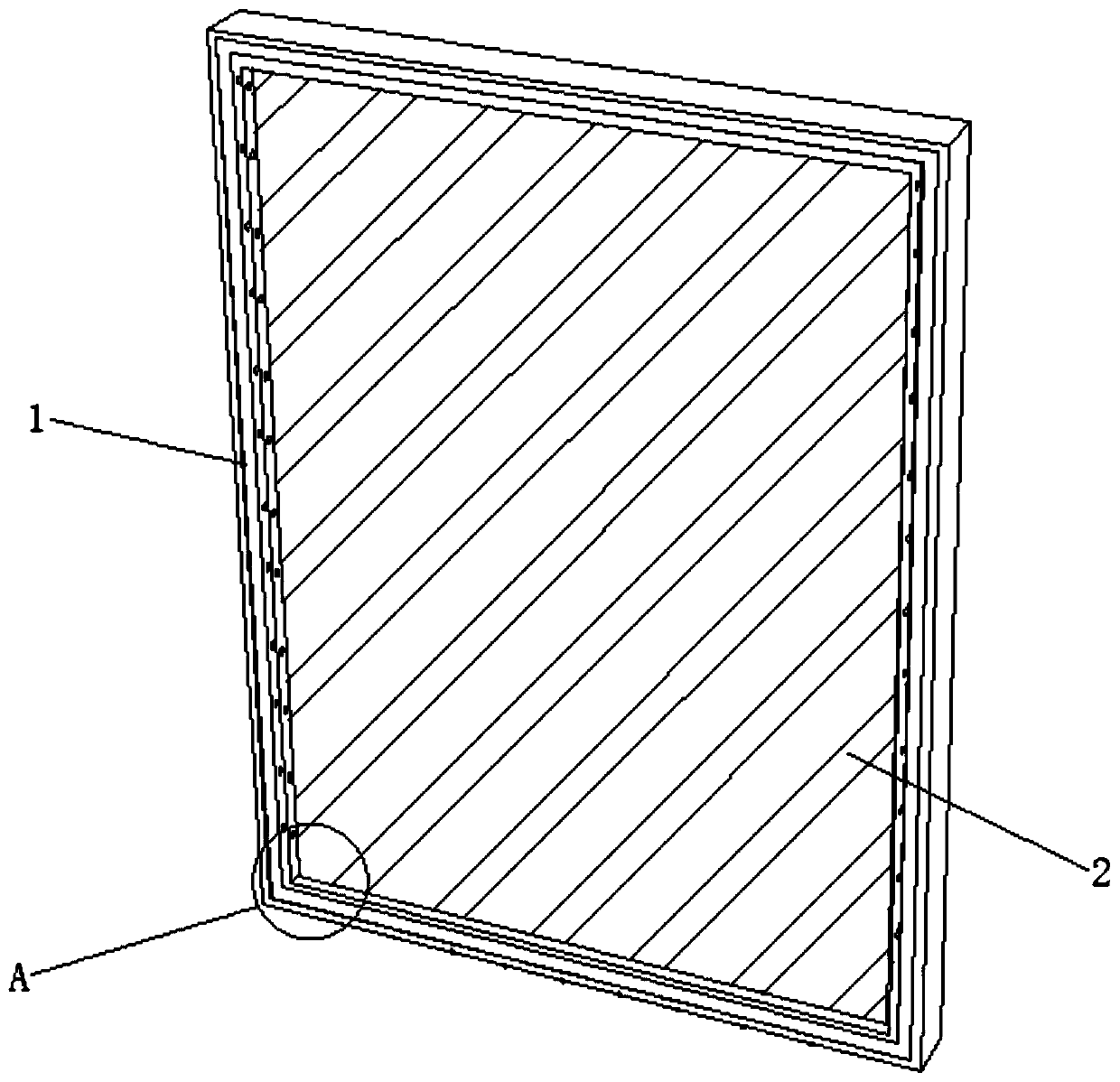

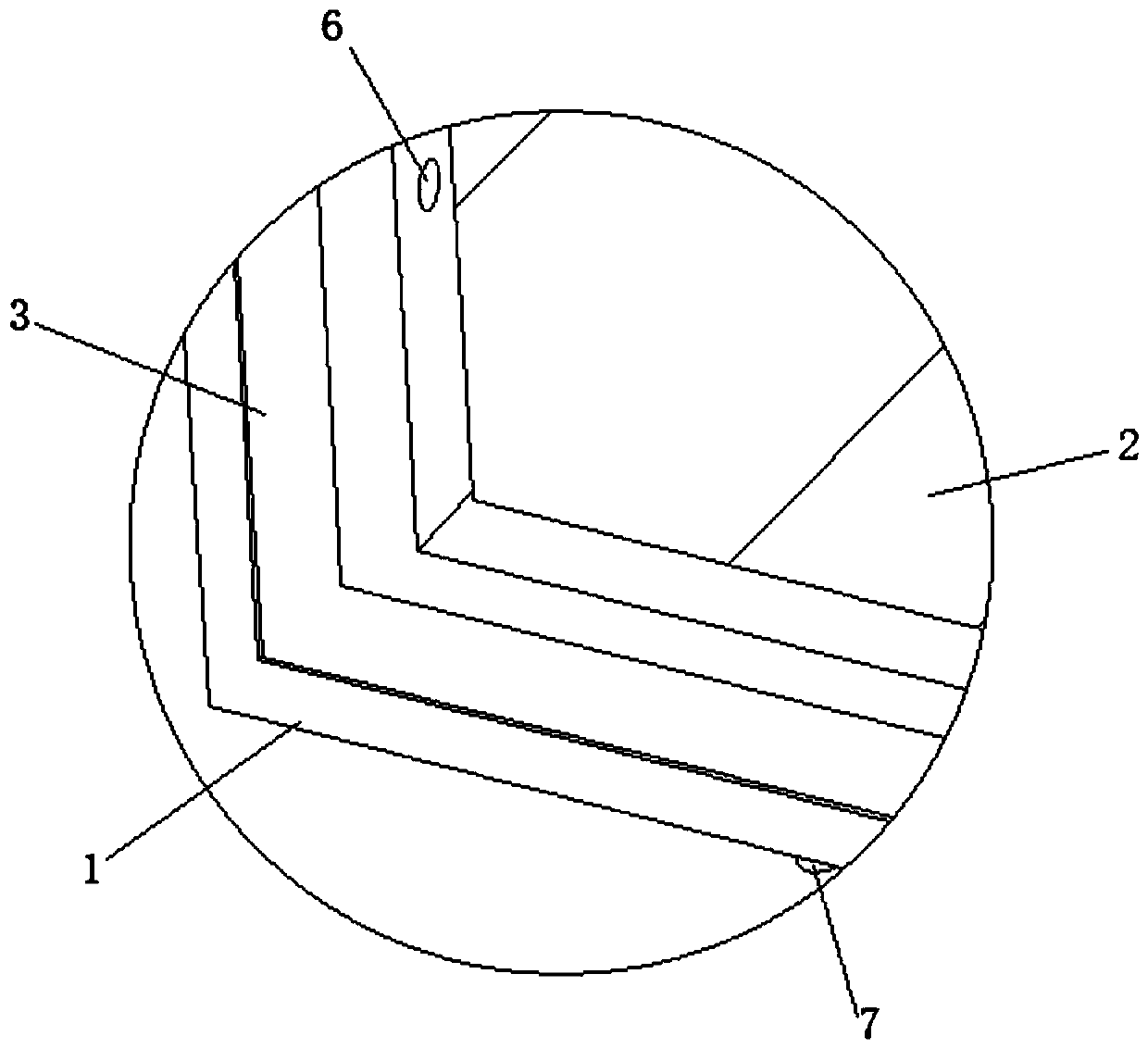

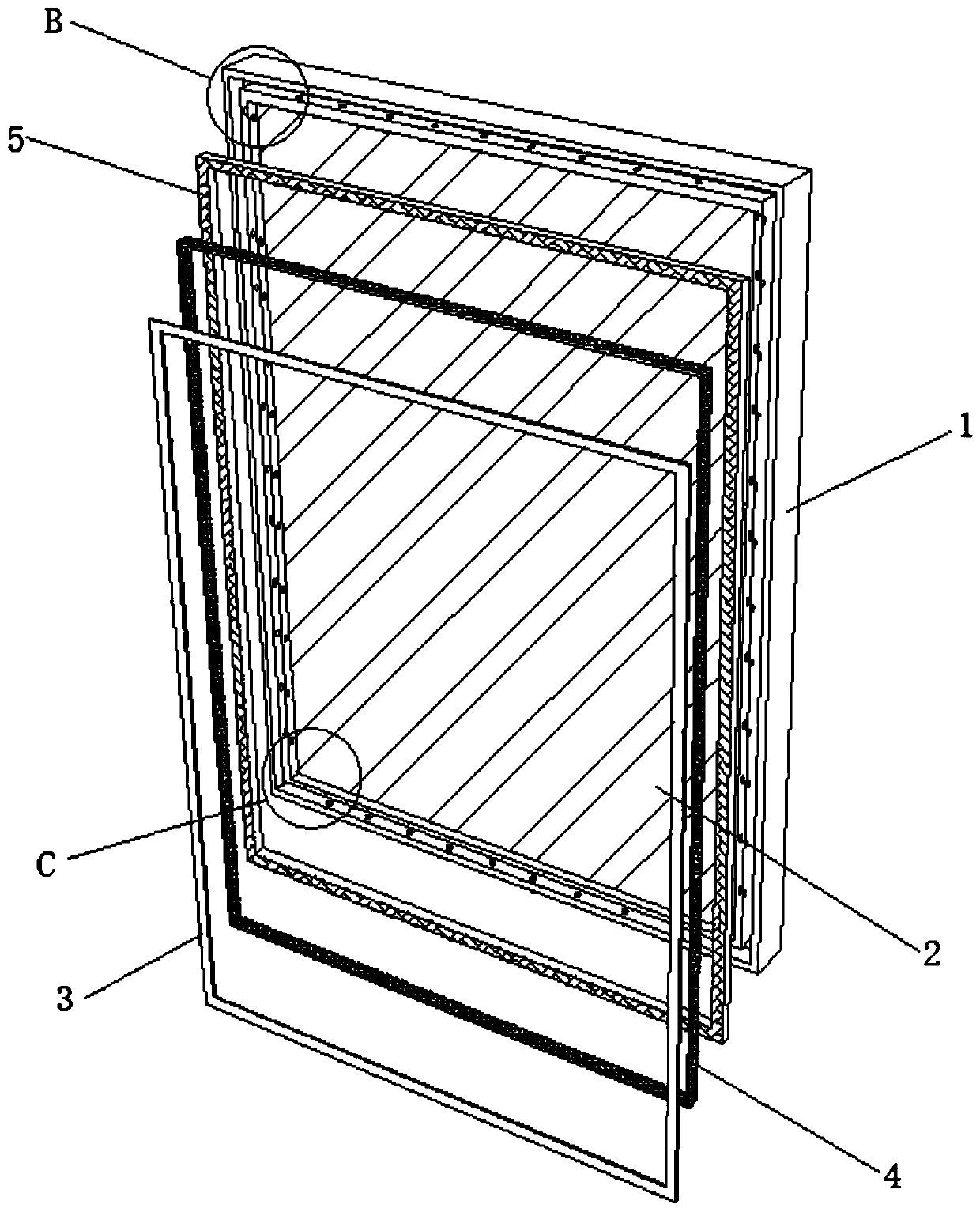

[0046] see figure 1 , image 3 and Figure 6 , an aluminum alloy door and window with hidden micro-drainage, including an aluminum alloy door and window frame 1 with a glass plate 2 installed inside, see image 3 , Figure 4 and Figure 5 , the front end of the aluminum alloy door and window frame 1 has a hidden drainage groove 8, and a water absorption frame 5 is arranged in the hidden drainage groove 8, please refer to figure 2 , the notch of the hidden drainage tank 8 is connected with a sealing cover frame 3, please refer to Figure 5 The lower end of the aluminum alloy door and window frame 1 is evenly dug with a plurality of water guide holes, and the embedded water absorbing rod 7 is fixedly connected to the water guide hole, and the upper end of the embedded water absorbing rod 7 extends to the inner side of the hidden drainage groove 8 and connects with the water absorbing frame 5 In contrast, the lower end surface of the embedded water-absorbing rod 7 exceeds t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com