Guiding device for guiding a chain-drawn sword plane

A technology of tow hook planer and chute section, which is applied in the direction of slitting machinery, earthwork drilling and mining, etc., can solve the problems of time-consuming, component position deviation, and reduce the service life or service time of the tow hook planer guide chute section, so as to achieve the guarantee Effect of shape stability and positional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

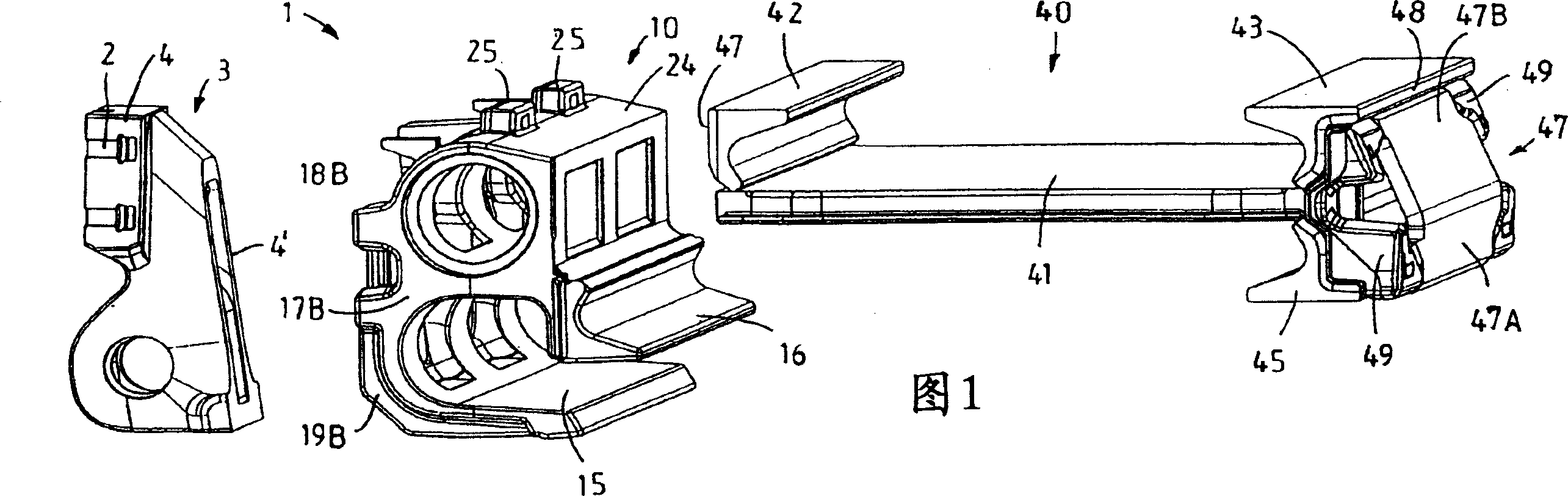

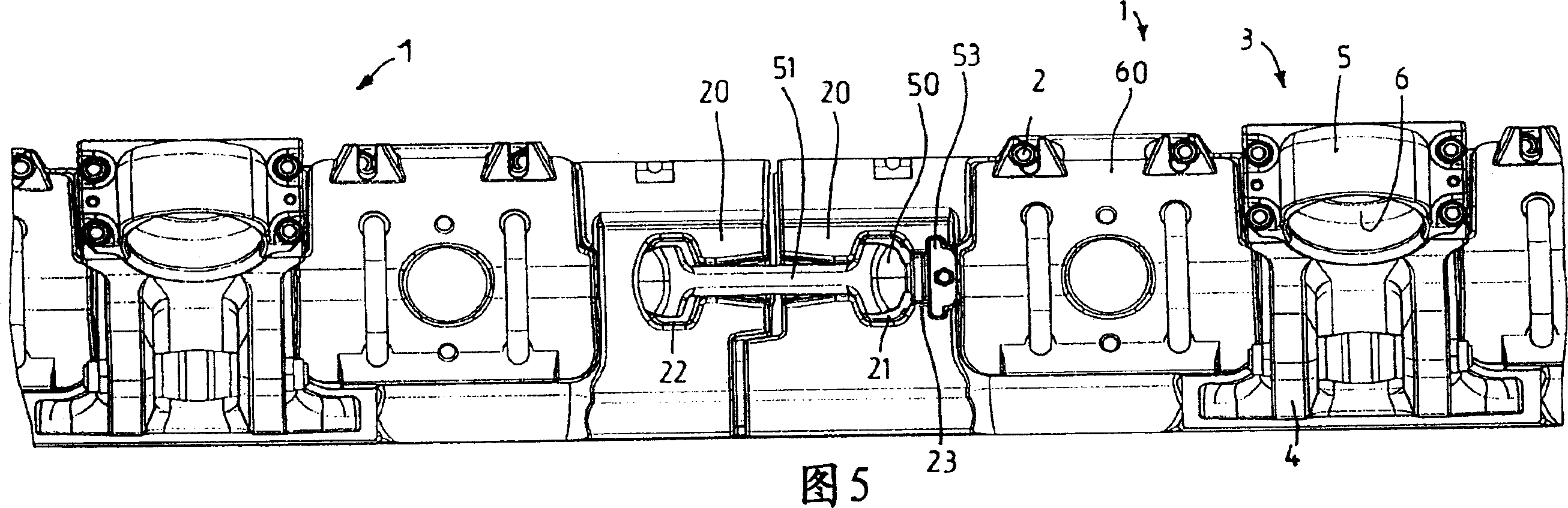

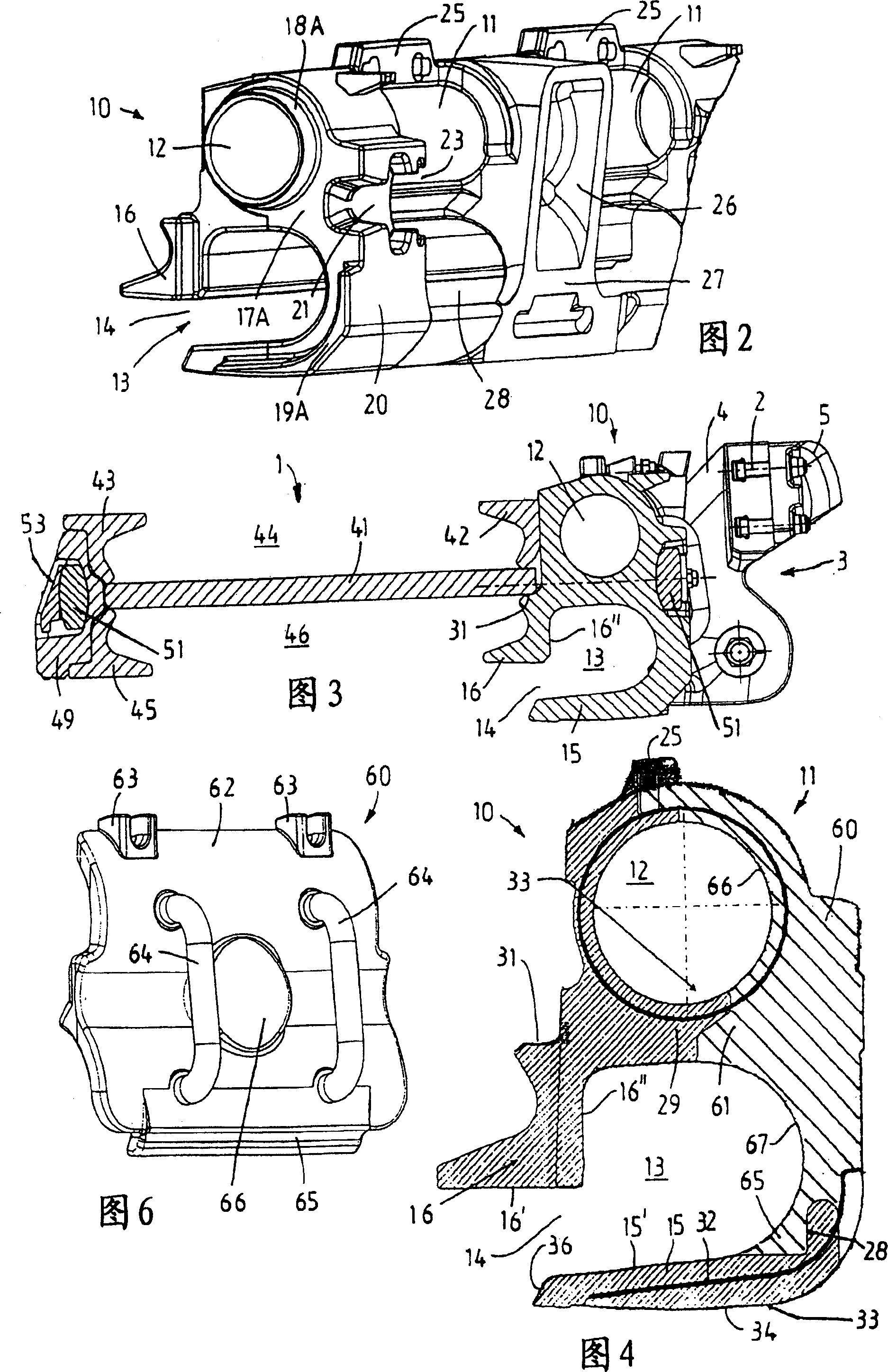

[0021] The tow hook planer guide chute section, generally designated 1 in the figures, can be combined with other, identically designed tow hook planer guide chute sections to form a tow hook planer guide with integrated conveyor. Each towing hook planer guide chute section 1 comprises a guide element 10 formed as a cast part, on which a conveyor chute element 40 formed as a welded structure is welded, the conveyor chute element is formed on the side of the guide element 10 facing the working surface. Welding is performed on the side with the welding face on the filling side. Each tow hook planer guide chute section 1 also includes a multi-piece connecting bracket 3 for articulated reception of the head of a not shown boom cylinder supported on a rear beam. To this end, the connecting bracket 3 comprises a base body 4 welded on the guide element 10 and a locking part 5 detachably connected to the base body via a screw connection 2 , which has a joint socket in the base body 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com