Cab hood structure, railway vehicle and production process

A preparation process and cab technology, applied in the field of vehicle engineering, can solve the problems of scrapped hood, high scrap rate, and difficult molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment provides a rail vehicle, for example, it can be a rail vehicle such as a subway or a high-speed rail, wherein the rail vehicle includes an underframe and a driver's cab hood structure, and the bottom of the driver's cab hood structure is installed on the underframe , and then installed on the track through the chassis.

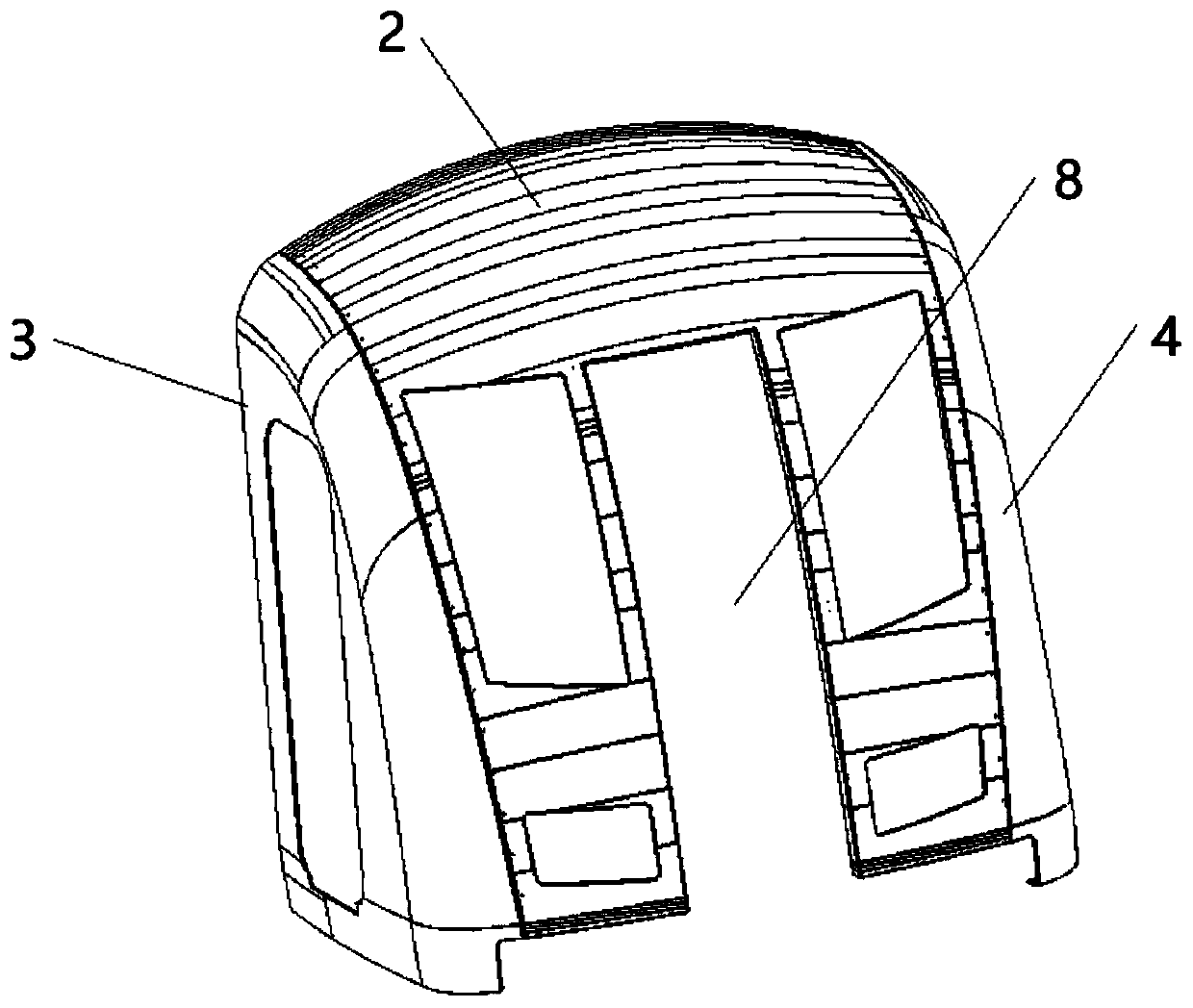

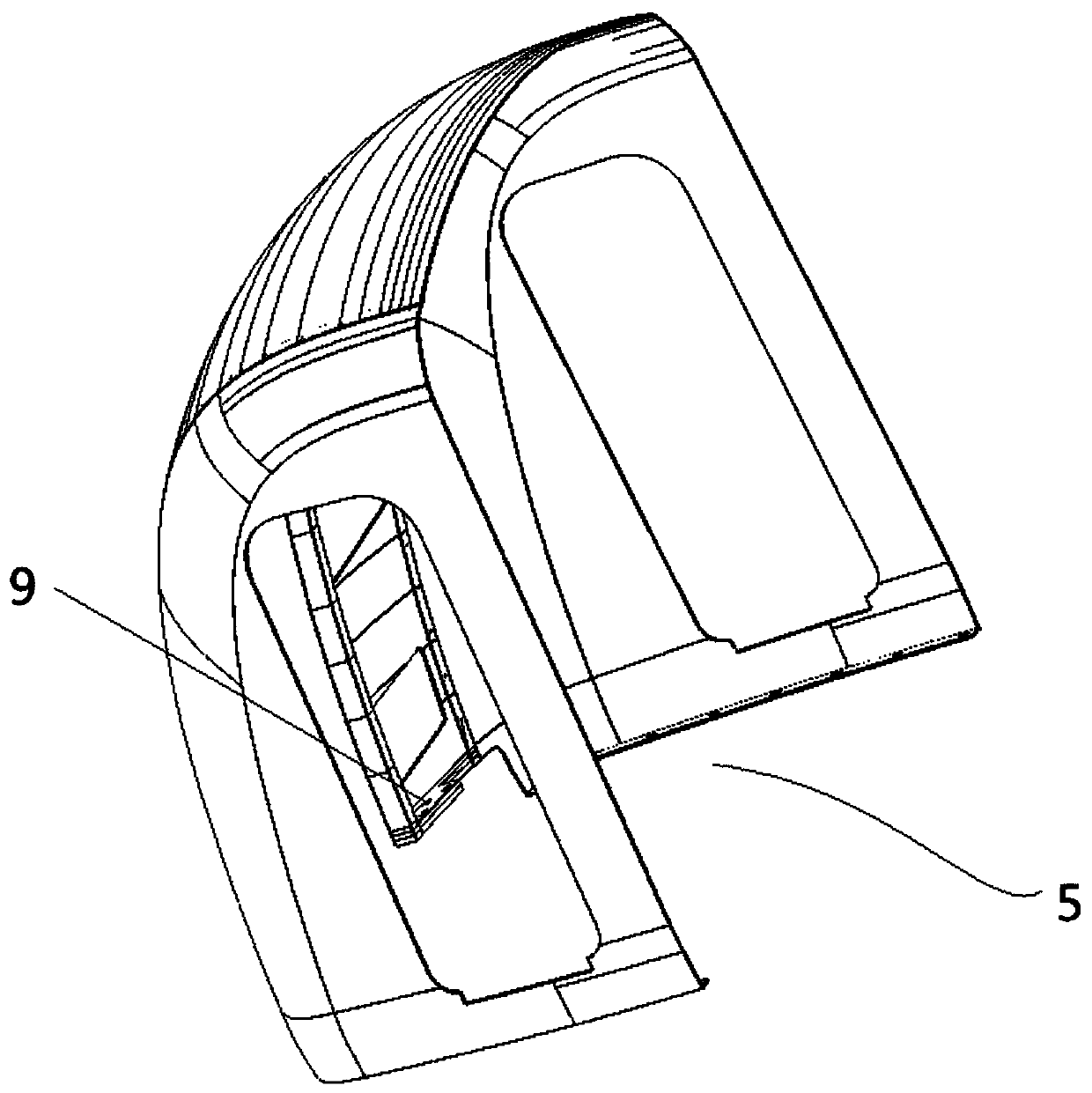

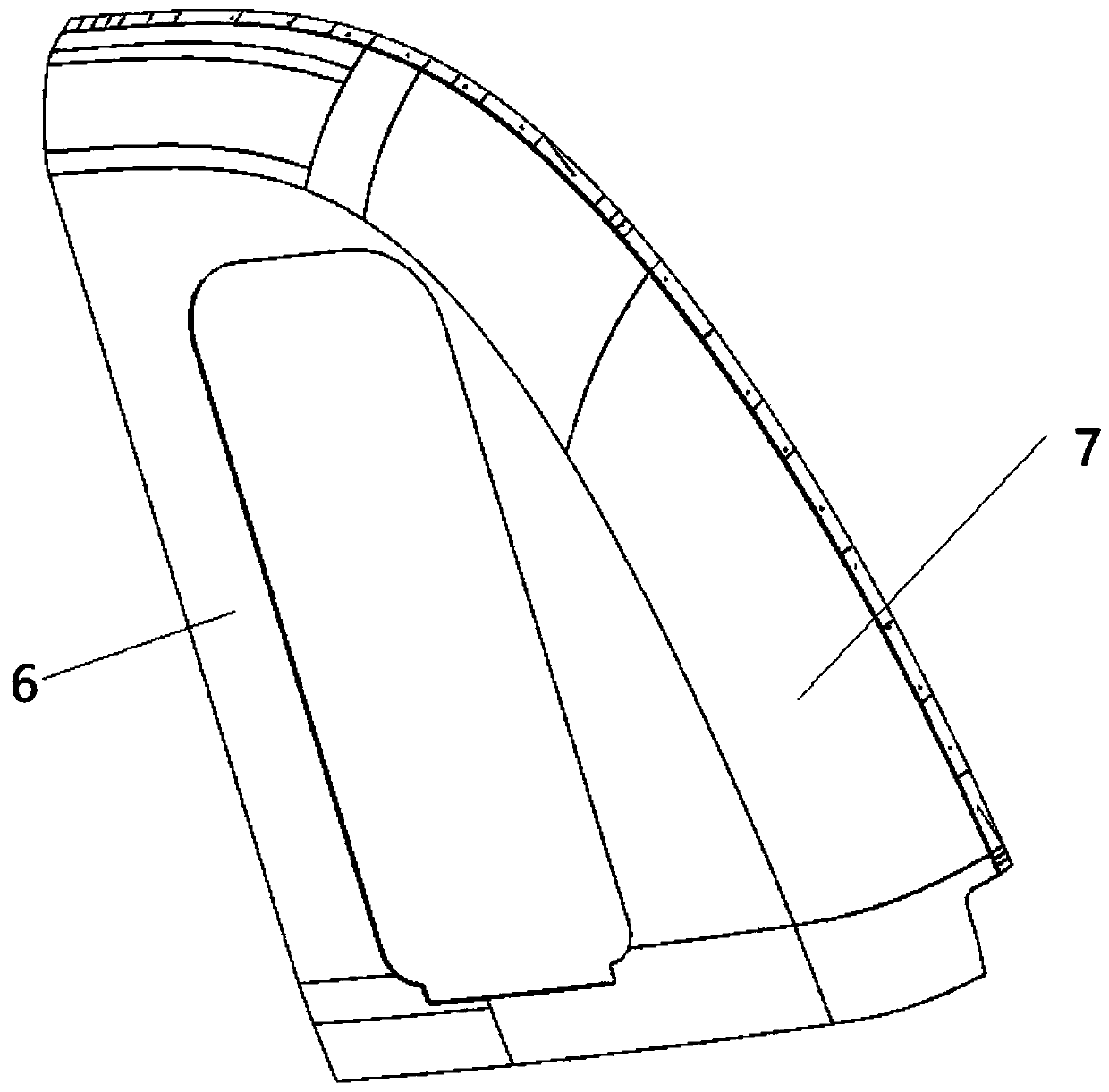

[0058] In this embodiment, the above-mentioned driver's cab hood structure includes at least two cover panels, and all the cover panels form the hood structure after being enclosed and fixed. Specifically, the cover panels can be set as a composite structure, which includes a body and At least one carbon fiber layer (not shown in the figure) and at least one toughening layer, the toughening layer and the carbon fiber layer are laid alternately, and then the resin body is filled in the holes of the carbon fiber layer and wrapped in all the alternate layers. Outside the carbon fiber layer and the toughening layer laid out, specifically, th...

Embodiment 2

[0065] This embodiment provides a preparation process for the structure of the driver's cab hood, which is used to prepare such as figure 1 In the driver's cab hood structure shown, each cover plate is formed first, which can be the above-mentioned main cover plate 2, left cover plate 3 and right cover plate 4, wherein the cover plate is a composite structure, specifically, aramid fiber fabric and The carbon fiber layers are laid alternately and are wrapped by the resin body to form a composite structure, in which the resin can be filled into the holes of the carbon fiber layers. The specific molding steps are as follows:

[0066] First of all, it is necessary to shape each cover plate, specifically, lay aramid fiber fabric and carbon fiber layer alternately on the inner wall surface of the lower mold, and secondly, clamp the lower mold and the upper mold so that the upper mold and the lower mold A cavity is formed between the upper carbon fiber layer and the aramid fiber fabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com