Breaker interlocking mechanism

A circuit breaker and interlocking technology, which is applied in the direction of switchgear, pull-out switchgear, electrical components, etc., can solve the problems of easy loss, unsightly appearance, and high cost, and achieve the effects of reducing carbon dioxide emissions, simplifying the number of parts, and avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

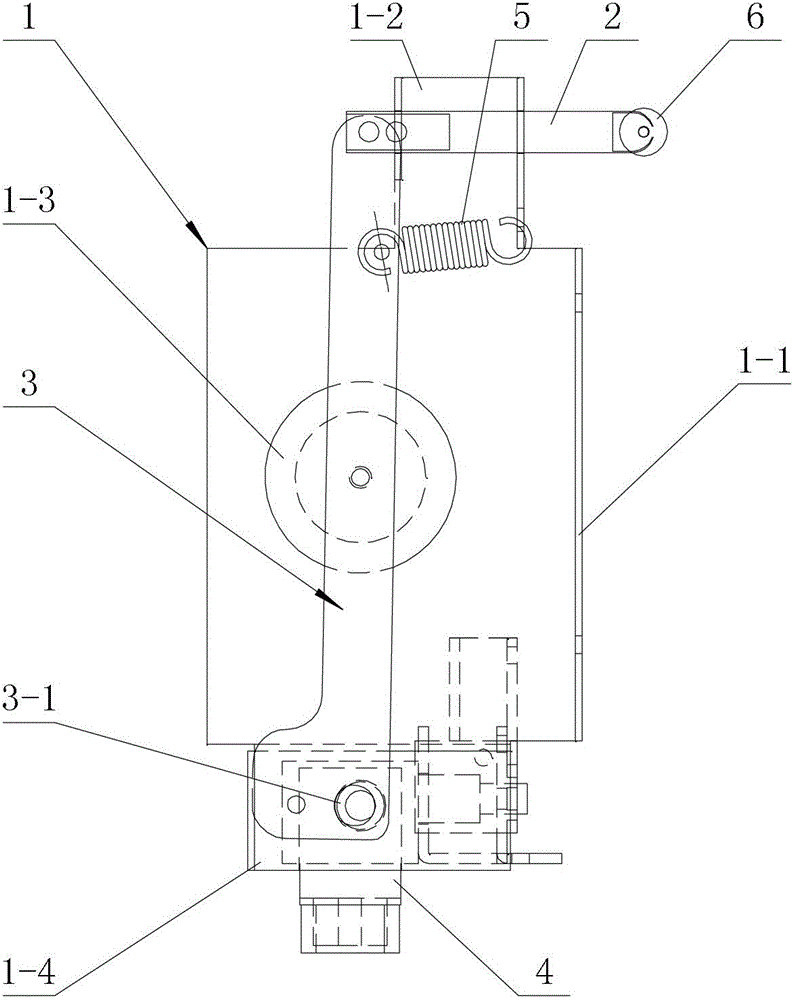

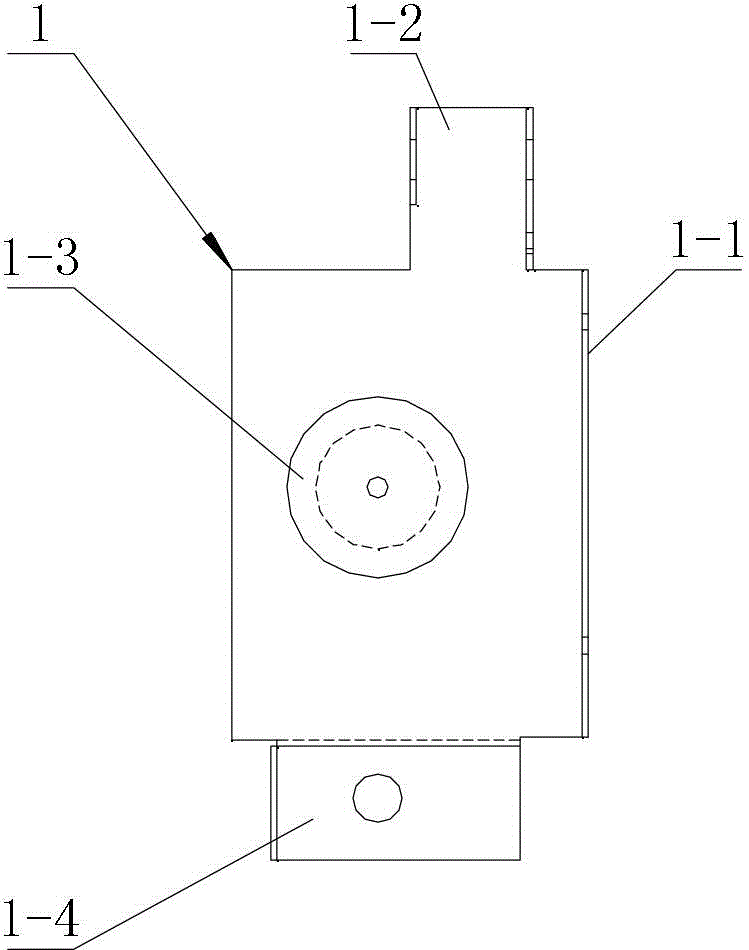

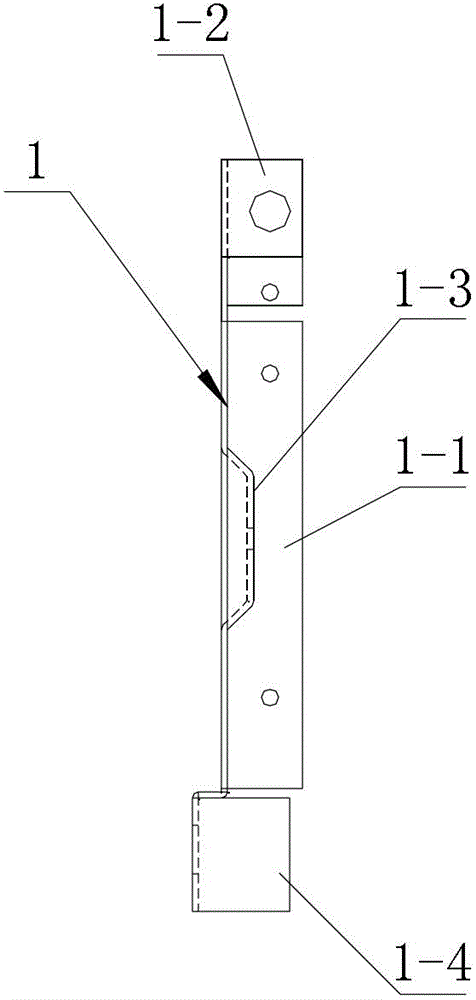

[0012] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0013] see Figure 1-Figure 3 , a circuit breaker chain mechanism, including a chain body 1, a lock rod 2, a chain drive plate 3, a lock body 4 and a return spring 5, the chain body 1 is an integrated structure formed by bending a steel plate, and the chain body 1 is a chain mechanism The supporting carrier of each component in it. The chain body 1 has a fixing part 1-1 for connecting with the handcart, and the chain body 1 and the handcart are connected by fasteners. The lock body 1 has a lock rod installation part 1-2 for installing the lock rod 2, that is, the lock rod 2 is movably fitted on the lock rod installation part 1-2, so as to realize the lock rod 2 stretching on the side of the handcart. The interlocking body 1 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com