Lithium battery and assembly method

A technology of lithium batteries and batteries, which is applied in the manufacture of lithium batteries, secondary batteries, non-aqueous electrolyte batteries, etc. It can solve problems such as poor bonding between tabs and collector plates, affecting discharge current, and large battery resistance. To achieve the effect of strengthening connection, precise connection and increasing current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

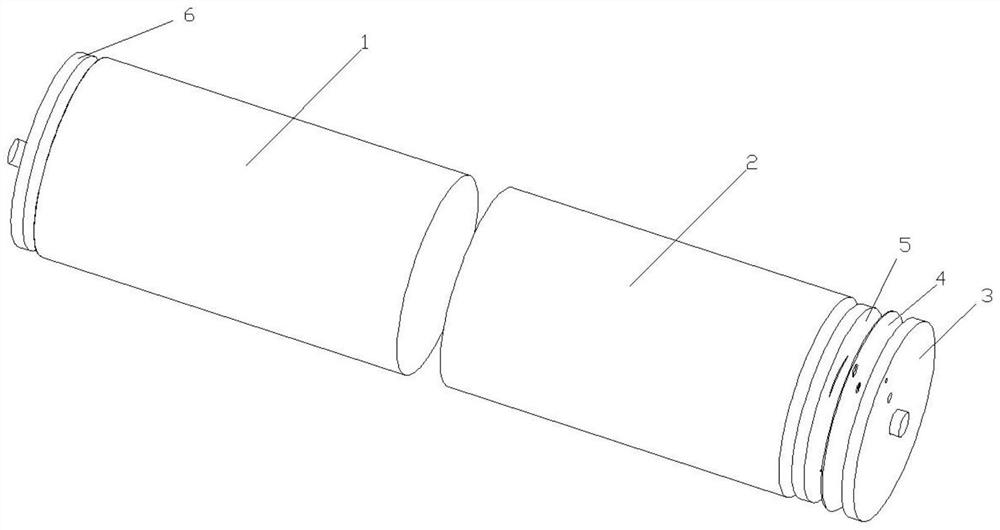

[0057] A lithium battery, characterized in that, comprising:

[0058] Housing 1 with positive and negative poles;

[0059] A cell 2 with a positive side and a negative side;

[0060] Positive cover plate 3;

[0061] Positive insulating sheet 4;

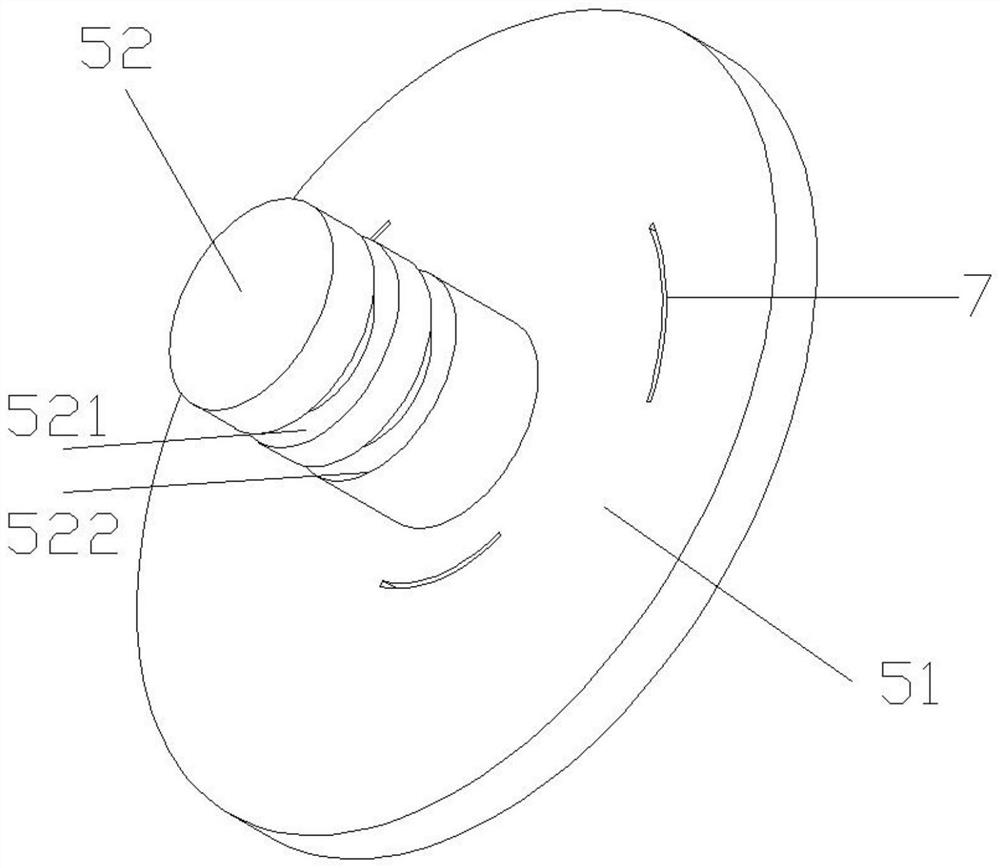

[0062] The positive electrode current collecting structure 5 includes a positive electrode current collecting disk 51 and a positive electrode current collecting column 52;

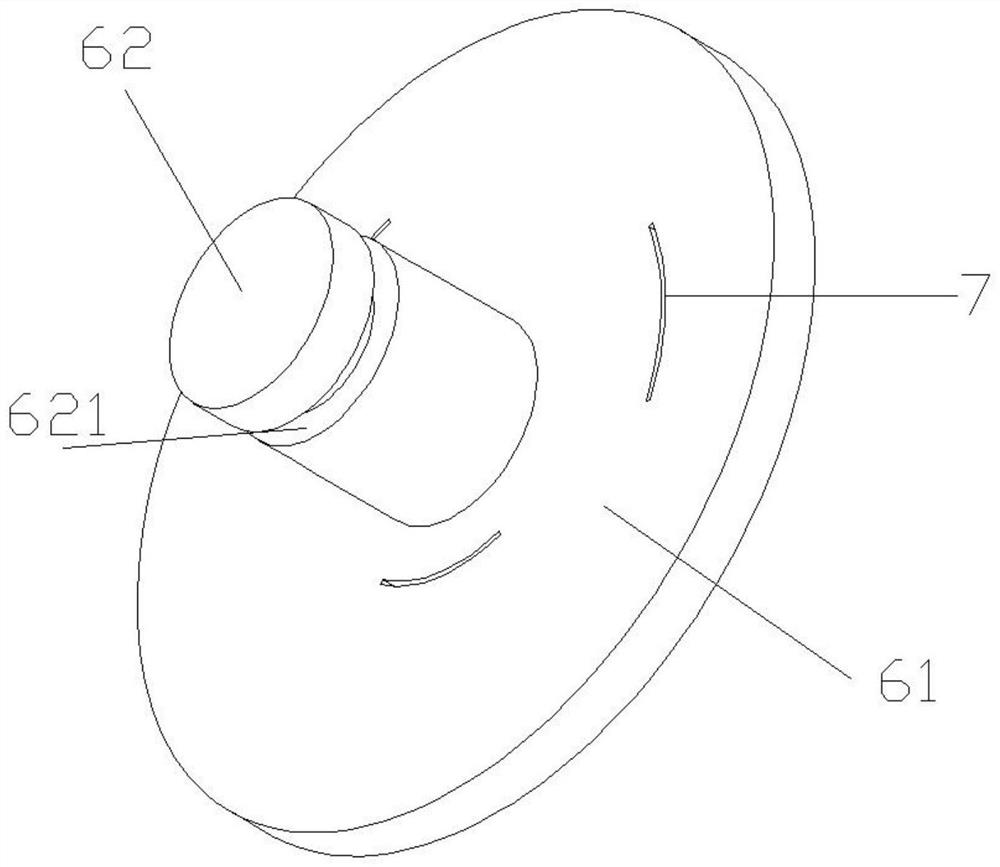

[0063] The negative electrode current collecting structure 6 includes a negative electrode current collecting disk 61 and a negative electrode current collecting column 62;

[0064] The casing 1 is a hollow cylindrical tube, the positive end is open, the negative end is closed, and an assembly through hole A is provided in the center of the surface of the negative end;

[0065] Wherein, the positive electrode current collecting column 52 is arranged in the center of the positive electrode current collecting disk 51, and is connected with the positive electrod...

Embodiment 2

[0074] The positive electrode current collecting disk 51 and the negative electrode current collecting disk 61 both include long arc holes 7, the long arc holes 7 are used for the electrode lugs to pass through, and the distribution positions correspond to the electrode lugs one-to-one.

[0075] In the prior art, the electrode tabs of the battery cores are closely attached along the lower surface of the current collecting plate, and the contacts are spot welded on the upper surface of the current collecting plate by means of laser welding. Since the tabs are located below the collector plate, spot welding is performed from the top of the collector plate during welding, and the tab position is in the blind area of the field of view. To accurately determine the position of the tabs, it is often impossible to weld the tabs on the current collecting plate in all directions, and the battery resistance is large, which affects the discharge current.

[0076] In this embodiment, the...

Embodiment 3

[0079] The positive electrode current collecting column 52 includes a first groove 521 and a second groove 522, and the negative electrode current collecting column 62 includes a third groove 621;

[0080] Wherein, the first groove 521 is used for assembling the positive cover plate 3, the second groove 522 is used for assembling the positive insulating sheet 4, and the third groove 621 is used for assembling the negative terminal of the casing;

[0081] The distance between the first groove 521 and the second groove 522 is 2 mm.

[0082] In this embodiment, grooves are arranged in the current collecting column to make the connection between the current collecting column and the cover plate, the insulating sheet and the casing more stable. During the use of the battery, the internal electrolyte reaction will generate gas and cause the battery to expand. A pressure relief valve is often set on the positive electrode cover plate of the battery. The positive electrode cover plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com