Full-automatic numerical control welding method and equipment

A welding equipment and fully automatic technology, applied in the field of machinery, can solve the problems of slow manual welding, labor-intensive, high energy consumption, and achieve the effects of good stability and uniformity, reducing welding costs, and reducing welding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

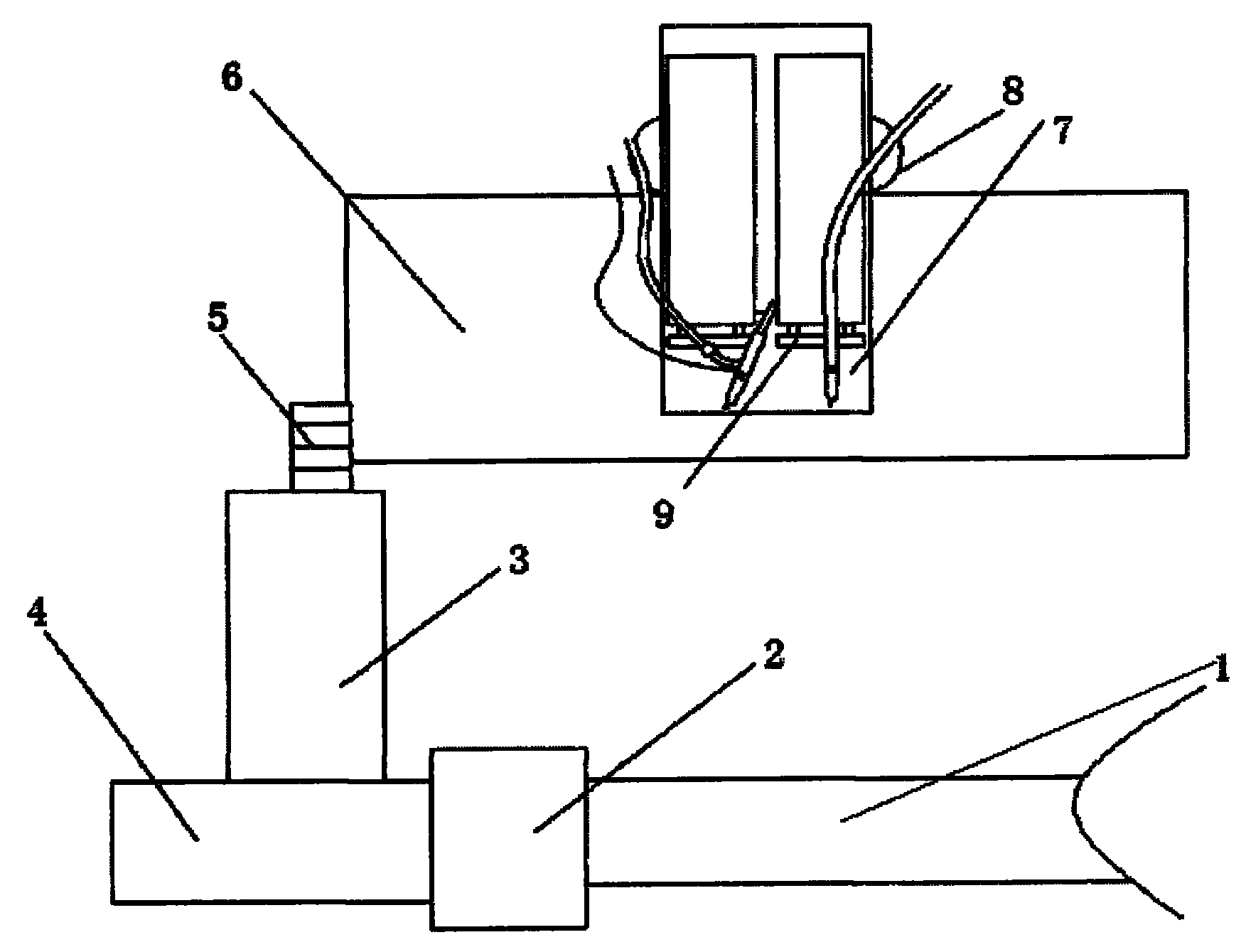

[0023] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

[0024] A fully automatic numerical control welding equipment is characterized in that it includes a positioning device, the positioning device includes an XYZ three-way moving device, includes a welding torch that can move with the positioning device, and also includes a grabbing device 2 with a clip at one end and a clamp at the other end. With the motor 4, the gripping device 2 can rotate. Therefore, in addition to precise positioning, the arc surface can also be controlled by rotation.

[0025] The torch includes two torches, namely a carbon dioxide shielded welding torch and an argon arc welding torch. Each contains an automatic switch, that is, opening and supplying air and stopping air can be automated.

[0026] The following provides two implementations of the XYZ three-way mobile device:

[0027...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com