Molybdenum and silicon substrate welding method in field emission device

A field emission device, silicon substrate technology, used in welding equipment, electric solid state devices, semiconductor devices, etc., can solve the problems of silicon wafer tearing, low welding strength, large deformation, etc., so that the connection will not break, improve Welding strength and the effect of blocking solder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Perform high-temperature vacuum annealing on the molybdenum sheet, the annealing temperature is 1000°C, and the annealing time is 20 minutes;

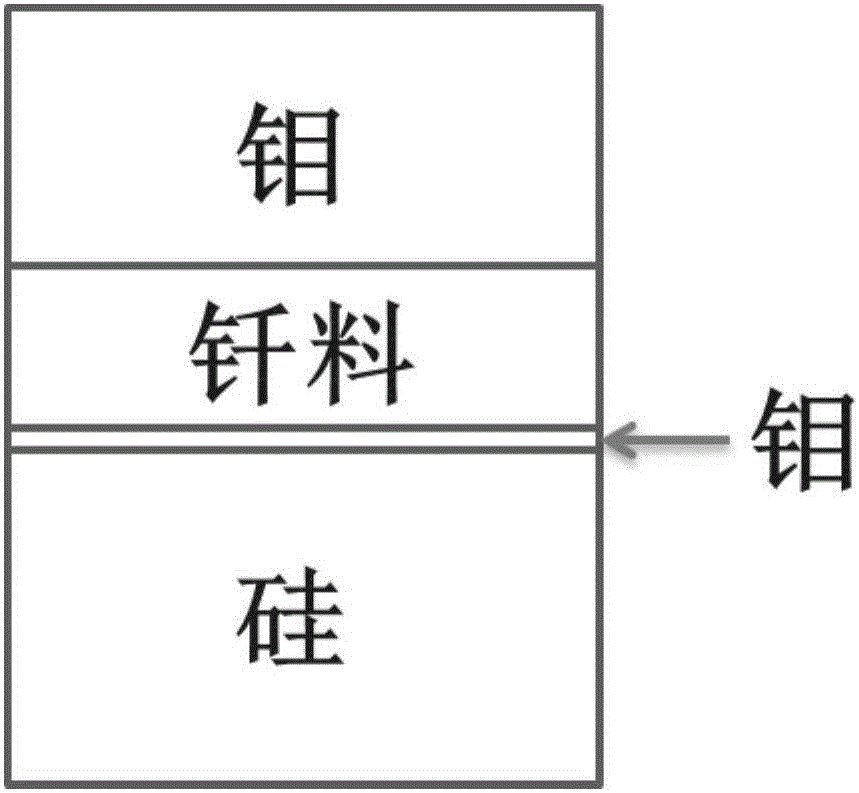

[0028] (2) Evaporate molybdenum thin film on silicon substrate by conventional thin film deposition method, and the system vacuum degree is 5×10 -4 Pa, molybdenum film thickness is 600nm;

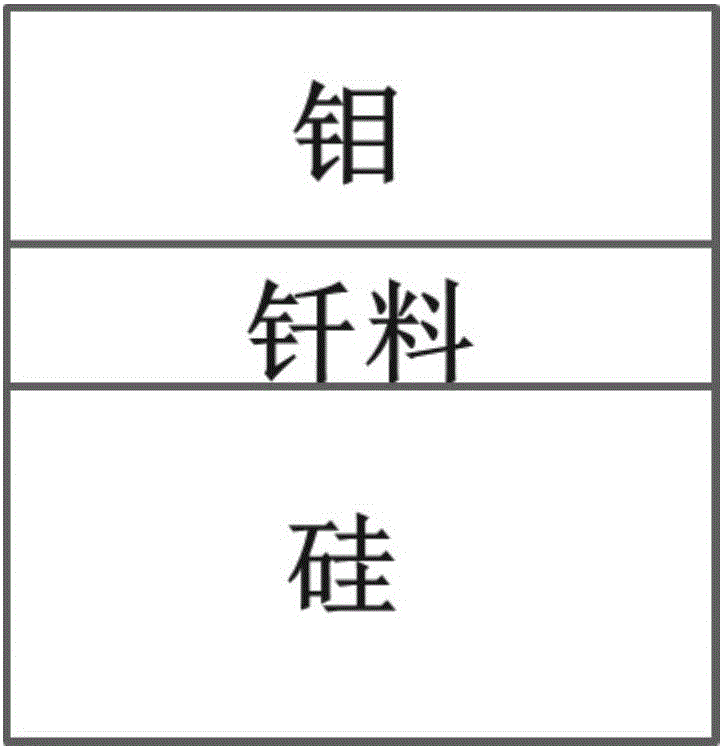

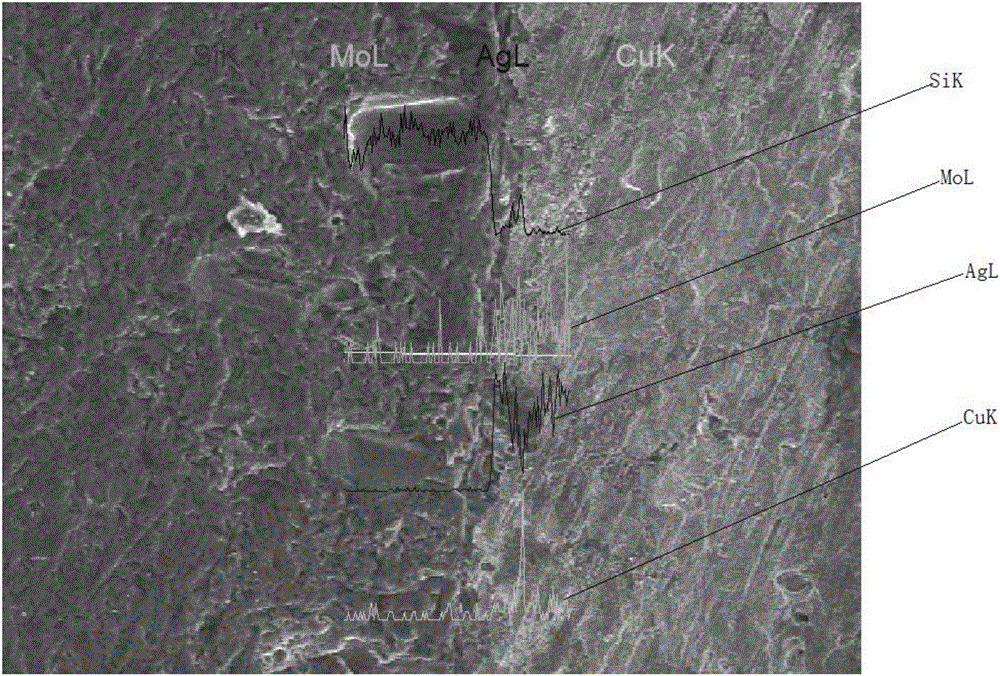

[0029] (3) The silicon substrate, copper-silver alloy sheet (silver-copper 28 welding sheet), and molybdenum sheet after molybdenum plating are stacked in sequence in a sintering furnace for high-vacuum sintering with a vacuum degree of 6×10 -4 Pa, the sintering temperature is 700°C, the holding time is 2min, the thickness of the silver-copper alloy is 0.03mm, and the thickness of the molybdenum sheet is 0.01mm.

Embodiment 2

[0031] (1) Carry out high-temperature vacuum annealing on the molybdenum sheet, the annealing temperature is 1200°C, and the annealing time is 60min;

[0032] (2) A molybdenum film was evaporated on a silicon substrate by a conventional film deposition method, and the vacuum degree of the system was 4×10 -4 Pa, molybdenum film thickness is 600nm;

[0033] (3) The silicon substrate, copper-silver alloy sheet (silver-copper 28 welding sheet), and molybdenum sheet after molybdenum plating are stacked in sequence in a sintering furnace for high-vacuum sintering with a vacuum degree of 4×10 -4 Pa, the sintering temperature is 800°C, the holding time is 2min, the thickness of the silver-copper alloy is 0.09mm, and the thickness of the molybdenum sheet is 0.09mm.

Embodiment 3

[0035] (1) Carry out high-temperature vacuum annealing on the molybdenum sheet, the annealing temperature is 1100°C, and the annealing time is 30min;

[0036] (2) Evaporate molybdenum thin film on silicon substrate by conventional thin film deposition method, the system vacuum degree is 2×10 -4 Pa, molybdenum film thickness is 600nm;

[0037] (3) The silicon substrate, copper-silver alloy sheet (silver-copper 28 welding sheet), and molybdenum sheet after molybdenum plating are stacked in sequence in a sintering furnace for high-vacuum sintering with a vacuum degree of 5×10 -4 Pa, the sintering temperature is 800°C, the holding time is 2min, the thickness of the silver-copper alloy is 0.05mm, and the thickness of the molybdenum sheet is 0.04mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com