Stirring head for friction stir welding

A friction stir welding and stirring head technology, used in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of easily damaged connecting parts, uncompact structure, difficult control, etc., to reduce the spindle unit structure, improve The effect of welding stability and simple spindle structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to more fully explain the implementation of the present invention, implementation examples of the present invention are provided. These implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

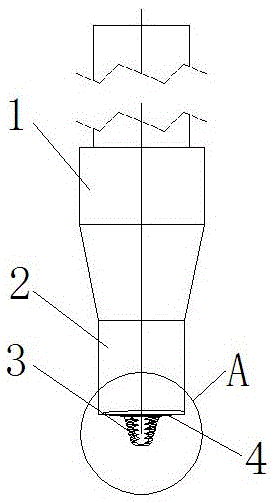

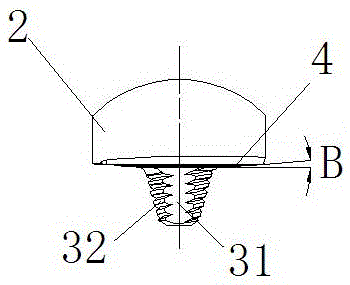

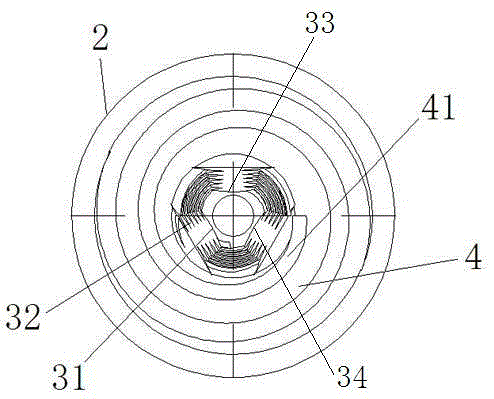

[0012] A further detailed explanation of the present invention is given in conjunction with the accompanying drawings. In the accompanying drawings, each mark is: 1: the clamping part of the stirring head; 2: the shaft shoulder of the stirring head; 3: the stirring needle; 31: the bevel a on the stirring needle; 33: the stirring needle 34: slope c on the stirring needle; 32: spiral groove on the stirring needle; 4: bottom surface of the stirring head shoulder; 41: involute spiral groove; as shown in the attached figure, a friction stirring The welding stirring head includes a stirring head clamping part 1 and a stirring head shoulder 2, a stirring needle 3 is located below the stirring head shoulder 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com