Modular efficient wire welding device

A modular and welding wire technology, applied in the field of modular high-efficiency welding wire devices, to achieve the effects of easy control, high efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

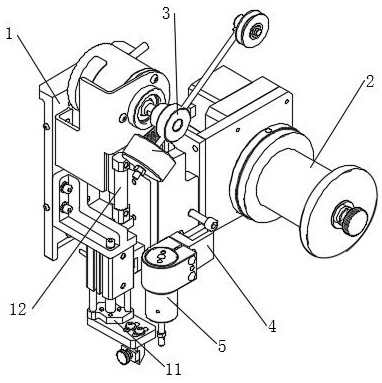

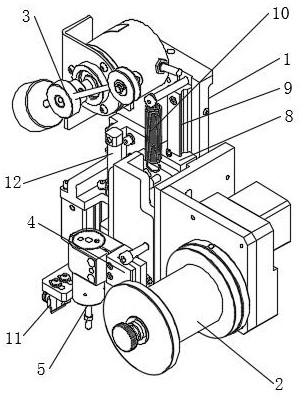

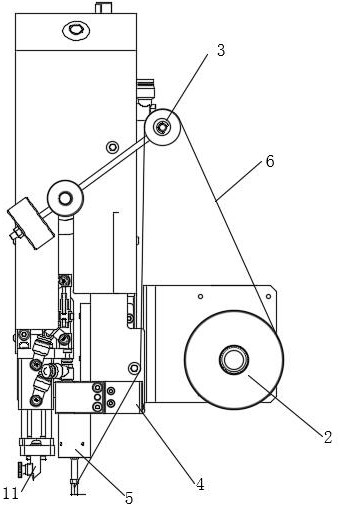

[0031] like Figures 1 to 3 and Figure 12 Shown is a schematic structural diagram of the present invention, a modular high-efficiency welding wire device, which is characterized in that it includes a mounting plate 1 on which a wire feeding module 2, a tensioning module 3, and a wire clamping module 4 are installed in sequence. , the liftable welding wire module 5 and the wire breaking module 11,

[0032] The wire feeding module 2 is responsible for feeding the wire 6;

[0033] The tensioning module 3 tensions the wire 6;

[0034] The wire clamping module 4 is responsible for clamping the wire 6;

[0035] The welding wire module 5 is responsible for welding the metal wire 6 to the material;

[0036] The wire breaking module 11 is responsible for cutting the metal wire 6 .

[0037] The specific action principle is as follows: the wire feeding module 2 transports the wire 6, and the tension module 3 tensions the wire 6, and then the wire 6 passes through the wire clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com