Grouting pipe with improved grouting effect and grouting process

A technology of grouting effect and grouting pipe, which is applied in the direction of shaft lining, tunnel lining, underground chamber, etc., can solve the problems of easy collapse, broken rock mass, unknown grout where to go, etc., to achieve firm installation, avoid grout loss, and ensure The effect of the grouting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

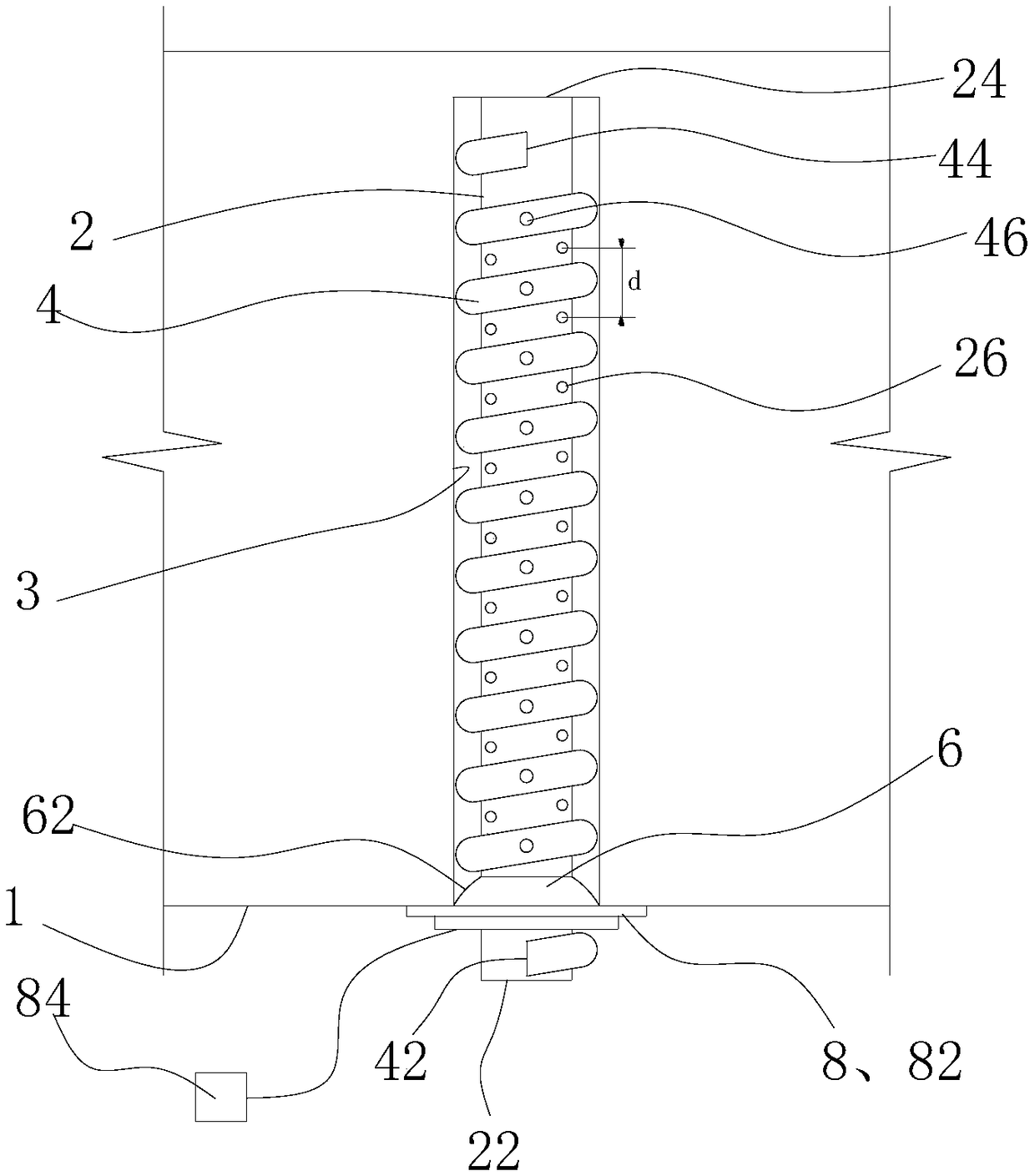

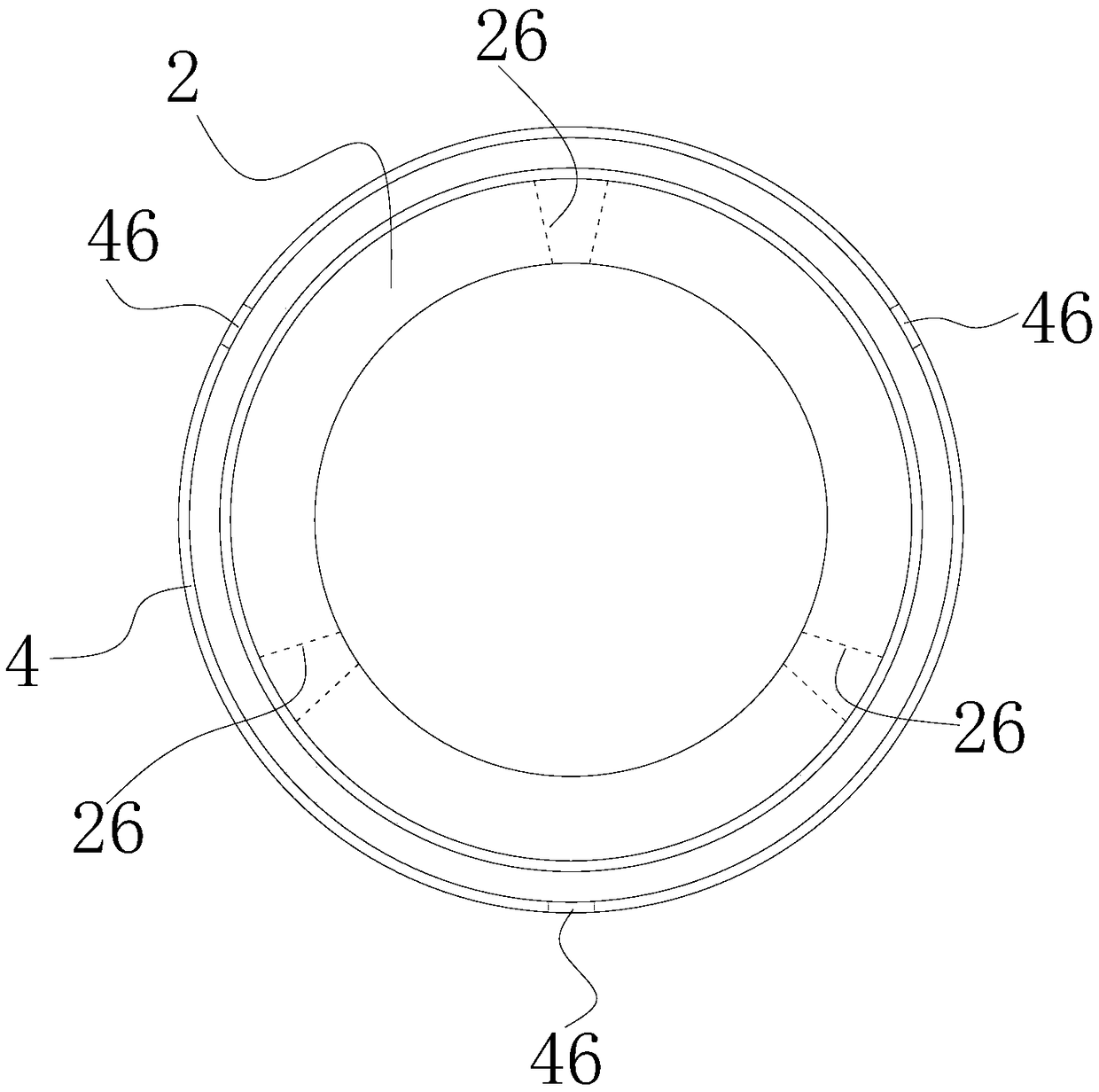

[0052] like Figure 1-4 As shown, a grouting pipe for improving the grouting effect includes a hollow tubular body 2, one end is a grouting port 22, and the other end is a grouting port 24. In addition, the side of the body 2 is also provided with a number of holes capable of releasing the grout. The first slurry outlet 26. In addition, the grouting pipe also includes a branch pipe 4 that spirally surrounds the outside of the body 2. One end of the branch pipe 4 near the grout inlet 22 of the body 2 is also provided with a branch pipe grout inlet 42, and the other end is a branch pipe outlet 44. A plurality of second slurry outlets 46 capable of releasing slurry to the outside are provided on the pipe body.

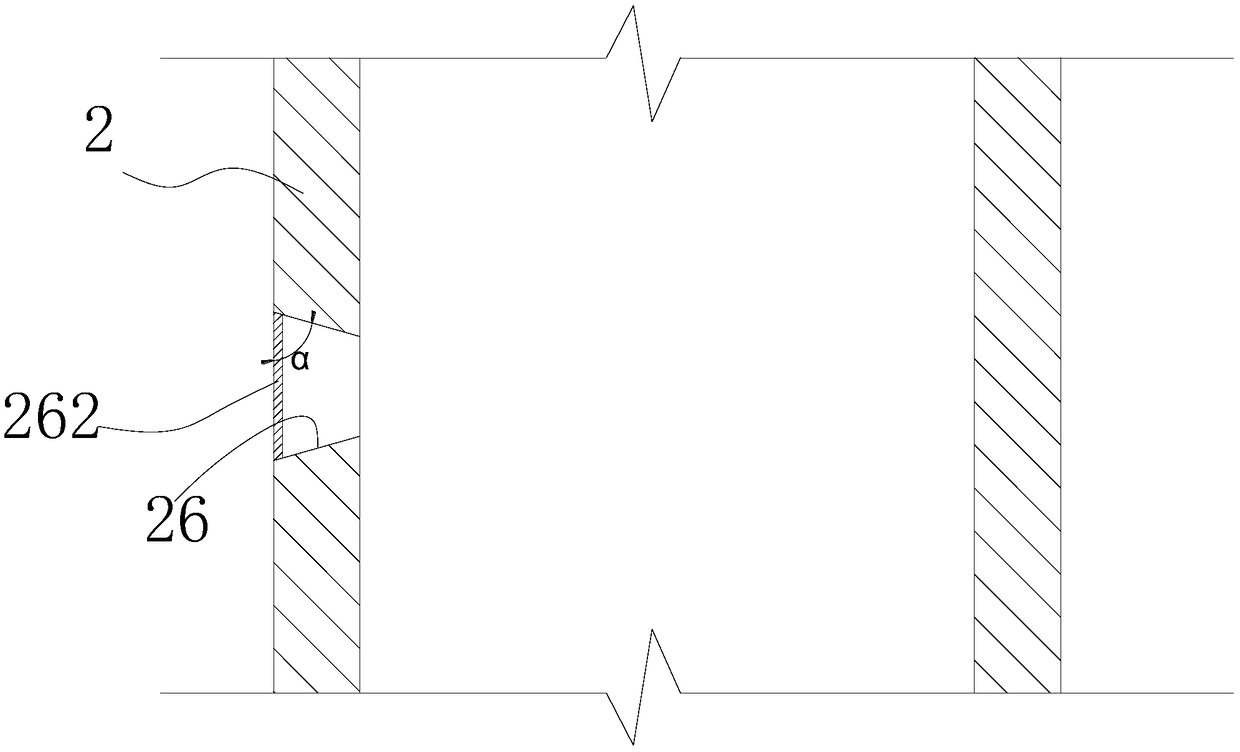

[0053] Specifically, the first grout outlet 26 is provided with a layer of thin wall 262 that can be broken through by the grouting pressure, and the second grout outlet 46 is also provided with a layer of thin wall 462 that can be broken through by the grouting pressure...

Embodiment 2

[0062] like Figure 2-7 As shown, a grouting pipe for improving the grouting effect is different from Embodiment 1 in that: the grouting pipe body 2 includes a plurality of tubular body units 28 connected end-to-end in the axial direction, and two adjacent body units 28 are detachably inserted Connected together, there is an overlapping portion 282 , and the first pulp outlet 26 is opened on the overlapping portion 282 . A tubular connecting piece 29 is also embedded in the first pulp outlet 26 on the overlapping portion 282 , and the two ends of the tubular connecting piece 29 have flanges respectively so as to connect the two body units 28 together. Specifically, the flanging at one end of the tubular connector 29 is a fixed annular flanging 292, and the other end is a separate three to four independent flanging 294, and the flanging 294 is a foldable metal or plastic sheet, which adopts the common When in use, the flange 294 is opened to be parallel to the axial direction ...

Embodiment 3

[0066] A kind of tunnel grouting process of the present invention, comprises the steps:

[0067] (1) Preparatory work, processing the grouting hole 3 at the target position of the tunnel;

[0068] (2) insert the grouting pipe of embodiment 1 in the grouting hole 3;

[0069] (3) Push the grout stopper 6 into the grouting hole 3, check the seal, and fix the grouting pipe on the operation target through the vacuum adsorption device 8;

[0070] (4) Inject mortar through the body 2 of the grouting pipe, and inject quick-setting agent through the branch pipe 4. Specifically, the grouting should be performed slowly first, so that the inner end of the grouting pipe is filled first, and then the entire cavity of the grouting pipe is gradually filled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com