Induced-type grouting construction method

A construction method and grouting technology, which are used in infrastructure engineering, soil protection, construction, etc., can solve the problem that the slurry in the closed stratum cannot be fully poured, the grouting effect cannot be achieved, and the slurry in the high-flowing water stratum is easily flowed by groundwater. problems such as flushing and scattering, to achieve the effects of simple operation, high grouting efficiency and high economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

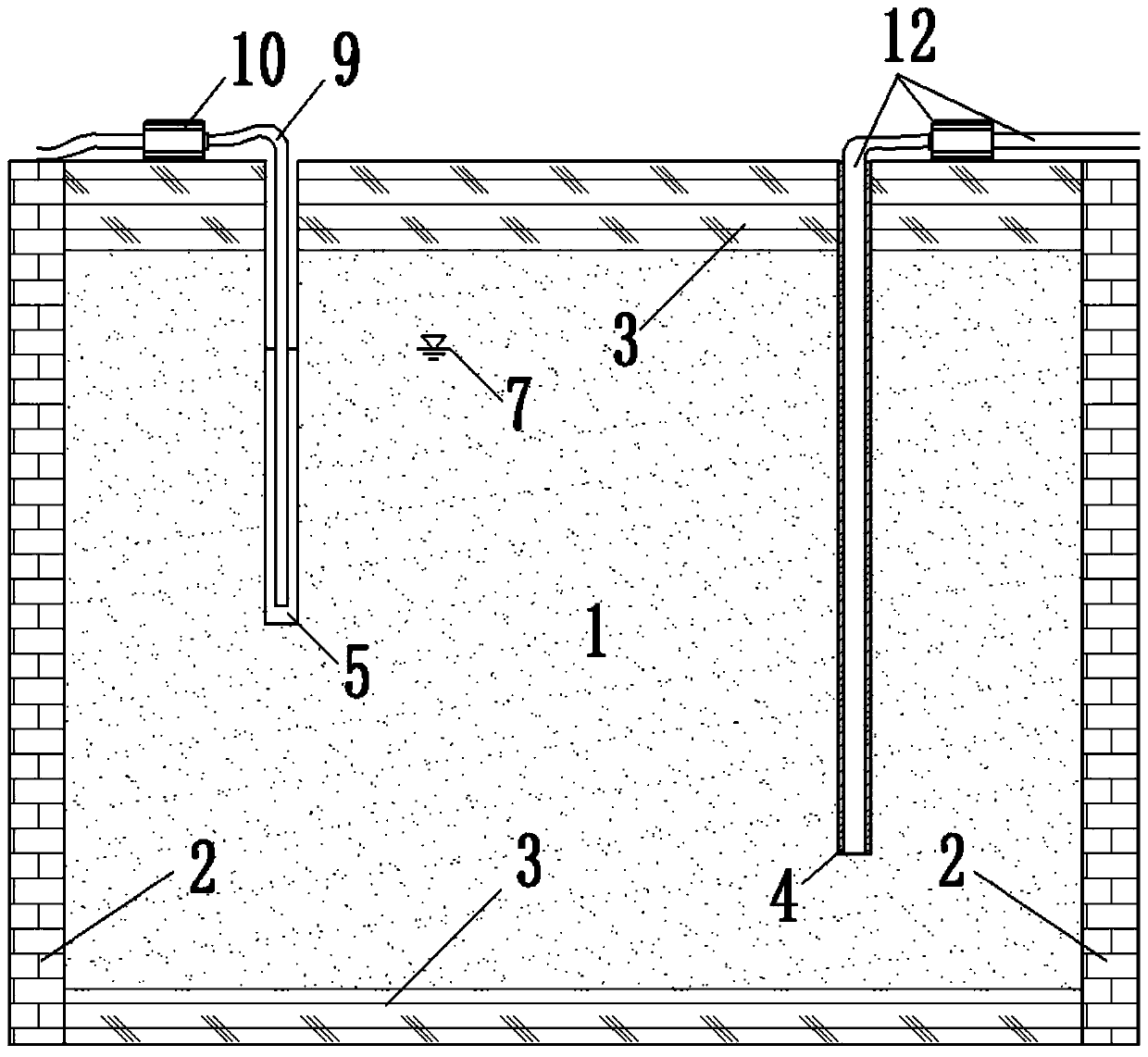

[0045] For such as figure 1 The closed stratum shown in the closed stratum is the stratum in which the four sides of the soil body 1 to be reinforced by grouting are support structures 2, and the upper and lower sides of the soil body 1 to be reinforced by grouting are the strata of the impermeable layer 3. An induced grouting construction method comprises the following steps:

[0046] A, design the grouting hole 4 on the soil body 1 to be grouted and strengthen, set the pumping hole 5 outside the grouting diffusion range of the designed grouting hole 4, and drill the pumping hole 5;

[0047] B, water pumping equipment is set, and described water pumping equipment comprises suction pipe 9 and the suction pump 10 that is connected with it, and described suction pump 10 is arranged on the ground, and described suction pipe 9 stretches in the described suction hole 5, and described suction pipe 9 The water intake of the water tank is lower than the groundwater level7;

[0048] ...

Embodiment 2

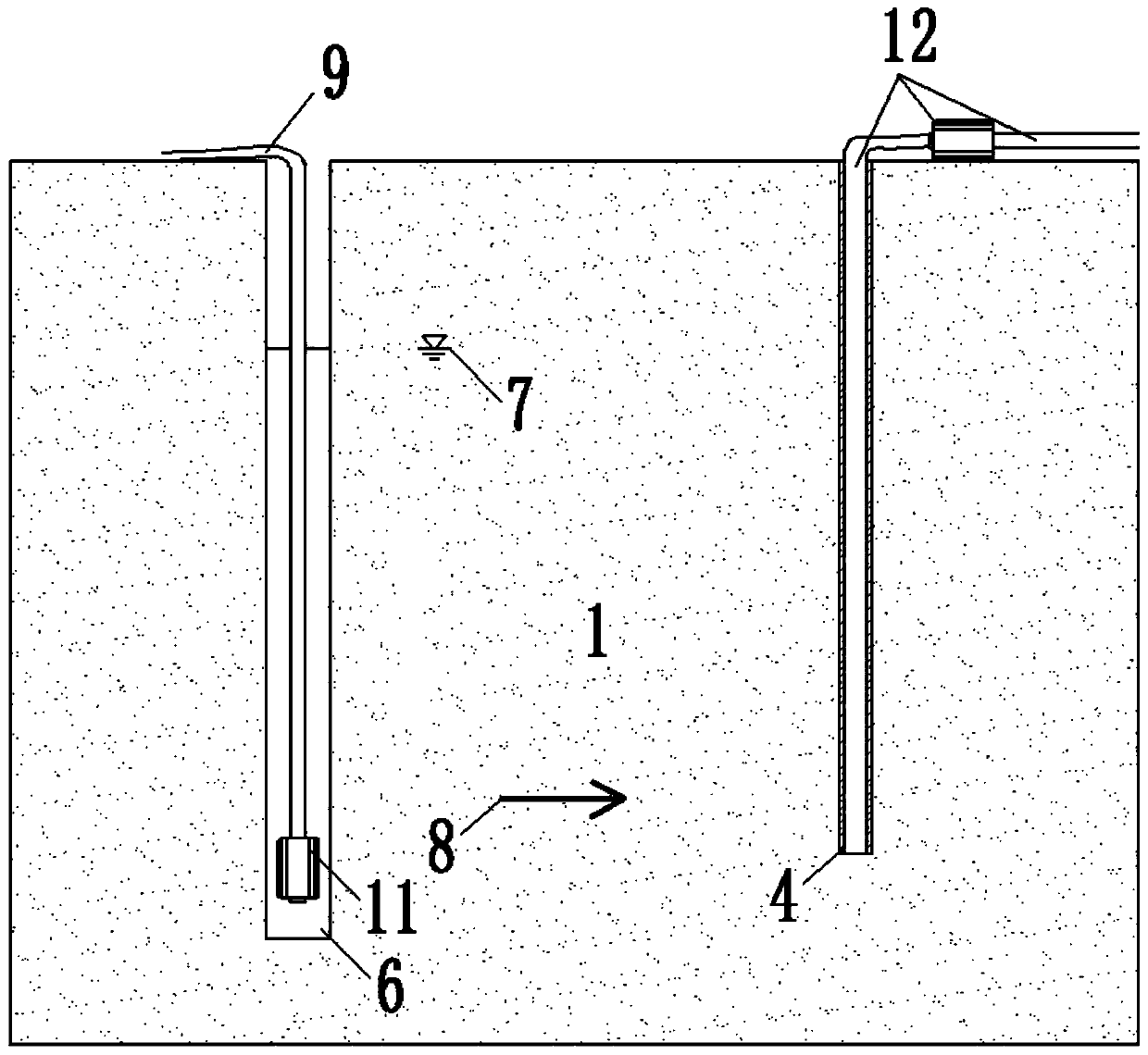

[0054] For such as figure 2 As shown in the high flow water formation, the high flow water formation is the formation where the groundwater flow rate in the soil body 1 is to be grouted and reinforced, and a kind of induced grouting construction method according to the present invention comprises the following steps:

[0055] a, design the grouting hole 4 on the soil body 1 to be grouted and strengthen, set the pumping well 6 outside the grouting diffusion range of the designed grouting hole 4, drill the pumping well 6, along the groundwater flow direction 8, The pumping well 6 is located upstream of the grouting hole 4;

[0056] B, pumping equipment is set, and described pumping equipment comprises suction pipe 9 and the submersible pump 11 that is connected with it, and described submersible pump 11 is arranged in described pumping well 6, and the bottom of the pump of described submersible pump 11 is lower than groundwater level 7 and below the grouting depth;

[0057] c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com